Method for electrode of satellite-borne electrostatic forming membrane reflector unfolding antenna

A technology of electrostatic forming and reflective surface, which is applied in the direction of antennas, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

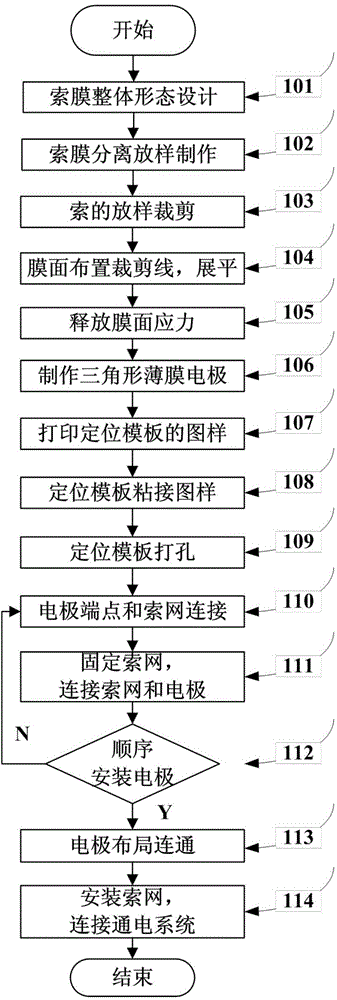

[0063] like figure 1 As shown, a method for deployable antenna electrodes on a space-borne electrostatic forming film reflector, at least includes the following steps:

[0064] Step 101: The high-voltage electrode is made of a flexible film material and laid on the front cable net of the astromesh structure. The cable net structure supporting the electrode and the flexible electrode are called an electrode system. The electrode system is a typical tensioned cable-membrane flexible structure, which relies on the pre-stress of the film and the pre-tension of the cable net to provide the stiffness required to maintain the shape of the structure. Therefore, the overall shape design of the cable-membrane composite structure should be carried out first according to the shape and stiffness requirements of the electrodes.

[0065] Step 102: According to the structural design results of the cable-membrane composite structure, the cable-net and the film are separated and staked out;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com