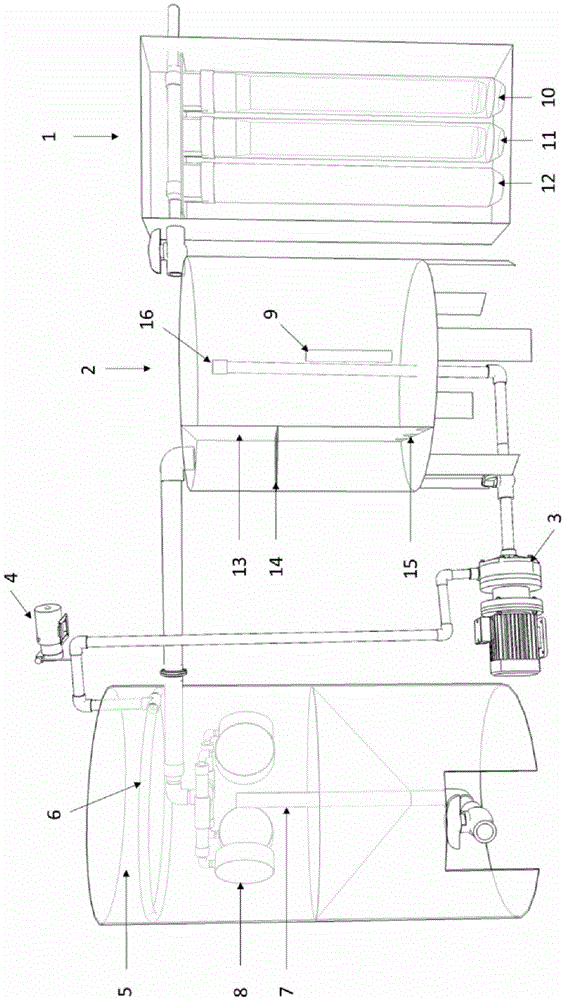

A high-density breeding system for large-scale oyster seedlings

A high-density seedling technology, applied in climate change adaptation, fish farming, application, etc., can solve the problems of large labor operation, low bait utilization rate, and large floor area, and overcome the large floor area , Improve the utilization rate of bait, and remove the effect of dead angle of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

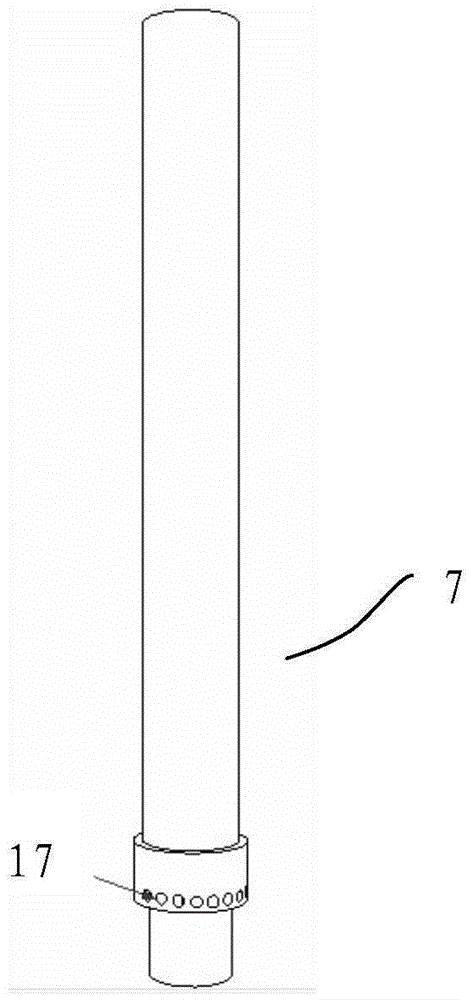

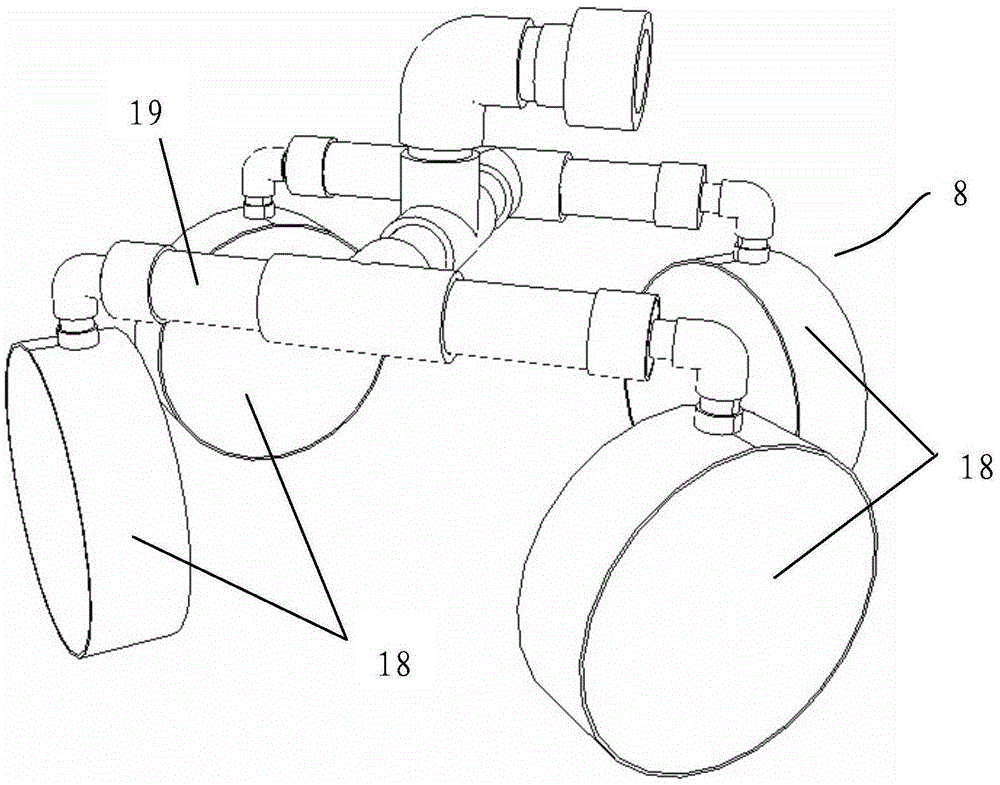

Method used

Image

Examples

experiment example 1

[0035] Breeding facility parameters: 500L of effective breeding water, 200L of water in the purification pool, air oxygenation DO maintained above 6.1mg / L, salinity 30-32, water temperature 21°C-27°C, pH 8.1-8.3.

[0036] The fertilized eggs of Portuguese oyster (Crassostrea angulata) after dissection, fertilization and egg washing were hatched to D-shaped larvae at a density of 80 / ml in the hatching bucket, and the shell length was about 70 μm at this time. Continue to cultivate for about 12 hours. After the shells of larvae harden and reach a shell length of 75 μm, they are collected, washed with purified seawater, and then transferred to the system of the present invention for cultivation. The initial stocking density is 52 / ml. After 30 days of cultivation, the larvae grow to an average shell length of 290 microns, and the survival rate is 91%. At this time, about 30% of the larvae have eye spots and can be transferred to the attached seedling pond for seedling picking. The...

experiment example 2

[0038] Parameters of breeding facilities: 500L of effective breeding water, 200L of purification pool water, air oxygenation DO maintained above 6.1mg / L, salinity 30-32, water temperature 26°C-29°C, pH 8.1-8.3.

[0039] The pretreatment process of the larvae is the same as in Example 1. The initial density of breeding is set at 100 / ml. After 23 days of cultivation, the larvae grow to an average shell length of 290 microns, and the survival rate is 65%. At this time, about 30% of the larvae have eyes. point, it can be transferred to the attached seedling pond for seedling picking. Feed dosage reference in the breeding process Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com