Bench vice with five degrees of freedom

A technology of bench vise and degree of freedom, applied in the direction of vise, clamping, support, etc., can solve the problems of personal casualties, large investment in CNC machining center equipment, unstable bench vise, etc., to achieve convenient operation, stable lifting, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

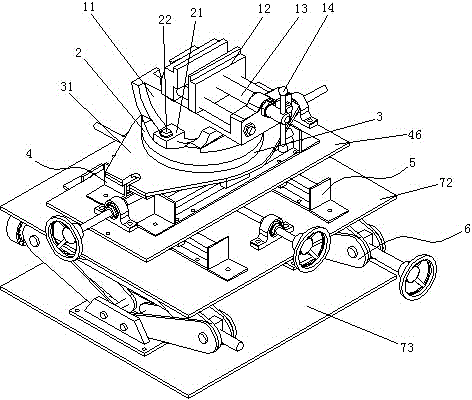

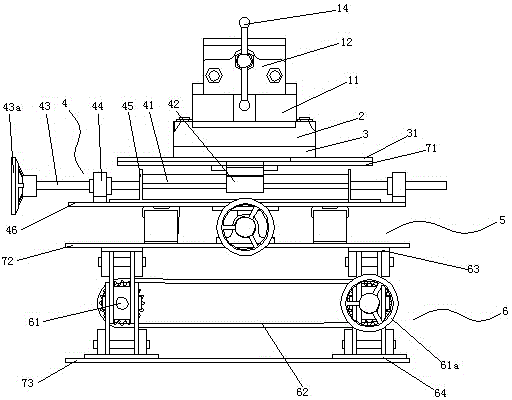

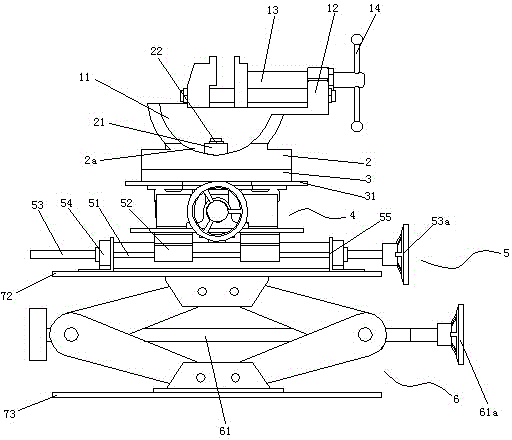

[0026] Such as Figure 1 to Figure 4 Shown is the structural representation of the present invention,

[0027] The reference signs therein are: bench vise clamp body 11, movable clamp table 12, clamp body screw rod 13, rocker handle 14, rotating disc 2, arc-shaped groove 2a, pressing block 21, fixing bolt 22, rotating base 3. Clamp base plate 31, X-axis moving mechanism 4, first guide rail 41, first guide rail slider 42, first screw rod 43, first hand wheel 43a, first bearing seat 44, first limit baffle 45 , support plate 46, Y-axis moving mechanism 5, second guide rail 51, second guide rail slider 52, second screw mandrel 53, second hand wheel 53a, second bearing seat 54, second limit baffle 55, lift Mechanism 6, control screw mandrel 61, control hand wheel 61a, transmission chain 62, jack top cover 63, jack bottom plate 64, upper bottom pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com