Manufacturing method and device of vanadium titanium smelting raw materials

A technology for preparing equipment and raw materials, which is applied in the field of vanadium-titanium smelting, can solve the problems of poor uniformity of iron content, agglomeration of waste materials, waste of mineral resources, etc., and achieve the effect of stable iron content, good uniformity and process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

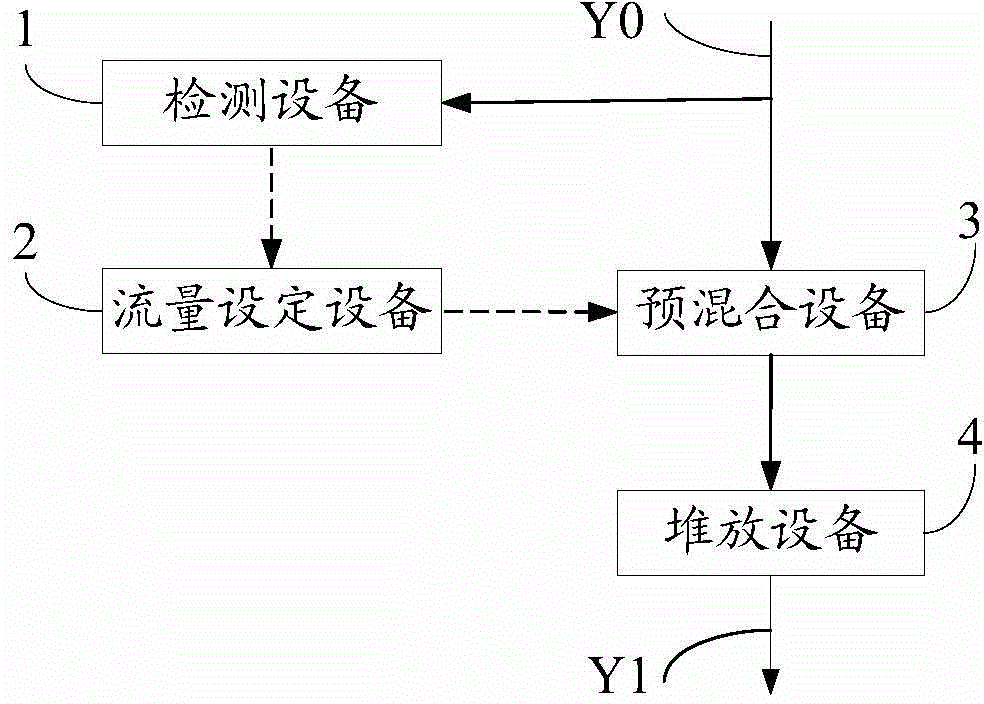

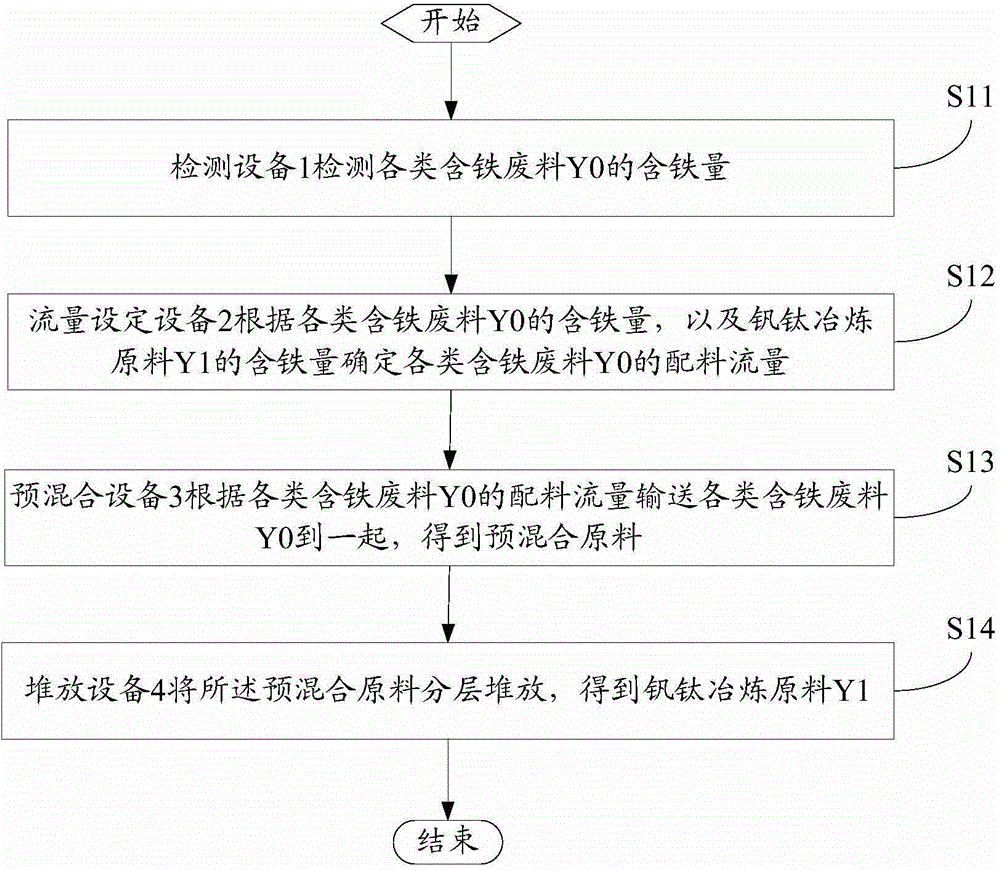

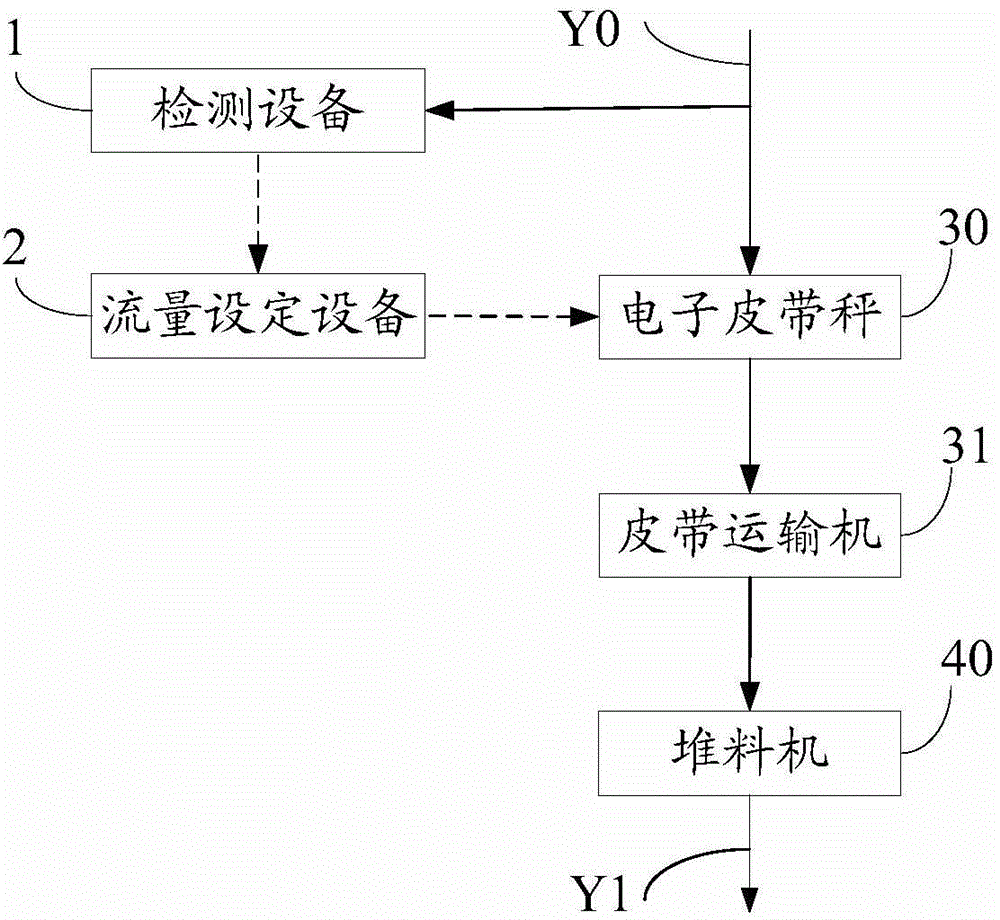

Method used

Image

Examples

Embodiment 1

[0035] In the first embodiment, various types of iron-containing waste Y0 are four kinds of iron-containing waste materials, which are steelmaking sludge, desulfurization slag, gravity ash, and dust ash. After testing, the iron content of various iron-containing waste Y0 is 50% iron content in steelmaking sludge, 50% iron content in desulfurization slag, 20% iron content in gravity ash, and approximately 35% iron content in dust removal ash.

[0036] In step S12, the flow setting device 2 determines the batching flow of various iron-containing waste materials Y0 according to the iron content of the various iron-containing waste materials Y0 and the iron content of the vanadium-titanium smelting raw material Y1.

[0037] The batching flow rate of the various types of iron-containing waste Y0 refers to the batching flow rate corresponding to each of two or more unmixed iron-containing waste materials. In combination with Example 1, according to the production requirements, the iron c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com