Device and process for removing lead and zinc elements from iron ore

An iron ore, lead-zinc technology, applied in the field of removal of impurity elements in iron ore, can solve problems such as unsatisfactory effect and uneven material layer temperature, and achieve the goal of reducing the content of lead and zinc, protecting the environment and being easy to realize Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

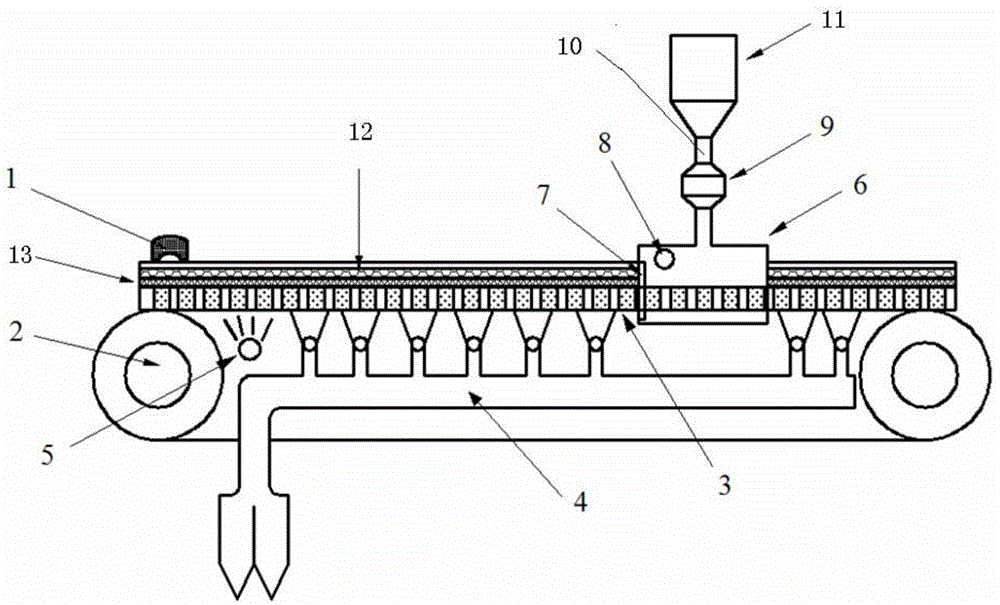

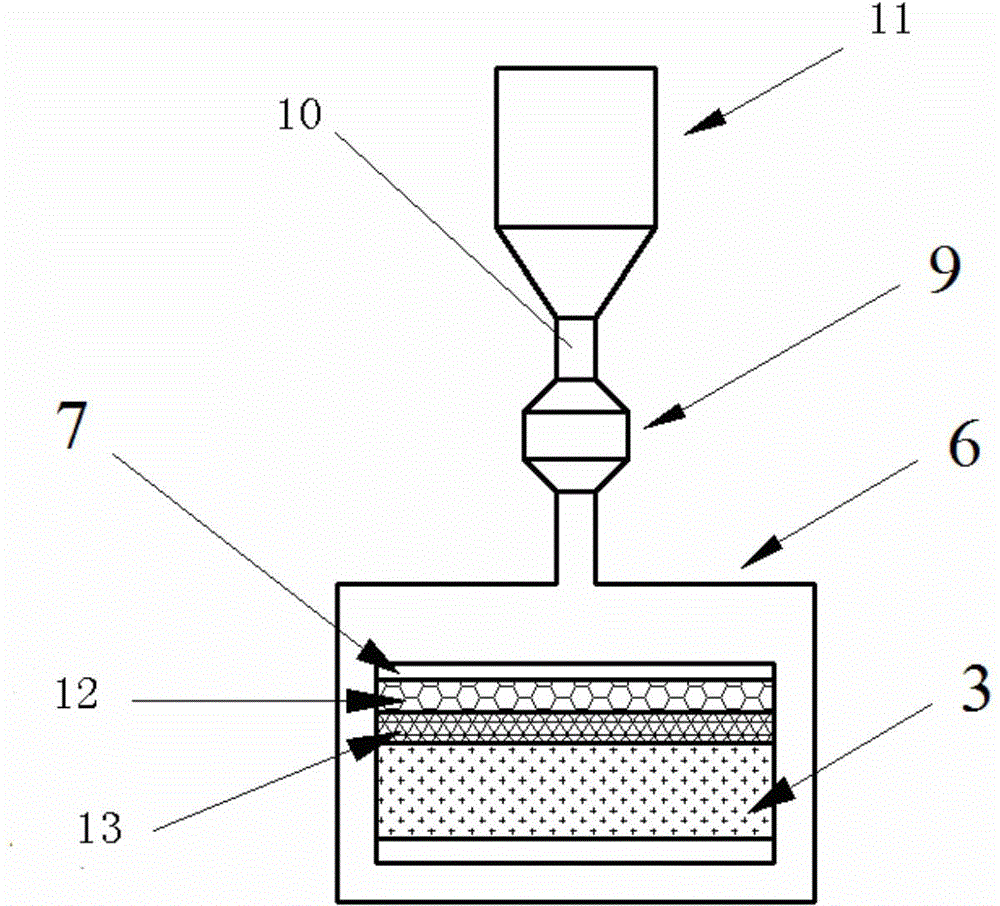

[0031] like Figure 1-2 As shown, a lead and zinc removal device in iron ore of the present invention includes a sintering machine and a heating device. A device for removing lead and zinc elements in iron ore, the device includes a sintering machine, a sealed heating device, a spraying device, an exhaust device, a cooling device and a bag for dust removal;

[0032] The sealing heating device is installed at the tail of the sintering machine, the spraying device is installed under the sintering machine, the dust removal bag is connected to one end of the exhaust device through the cooling device, and the exhaust device The other end communicates with the sealed heating device;

[0033] The sealed heating device includes a sealed furnace body, a heat storage layer, a burner and a gas supply device. The inner wall of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com