Condensing device for vacuum coating equipment

A condensing device and vacuum coating technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve problems affecting the smoothness of steam circulation and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

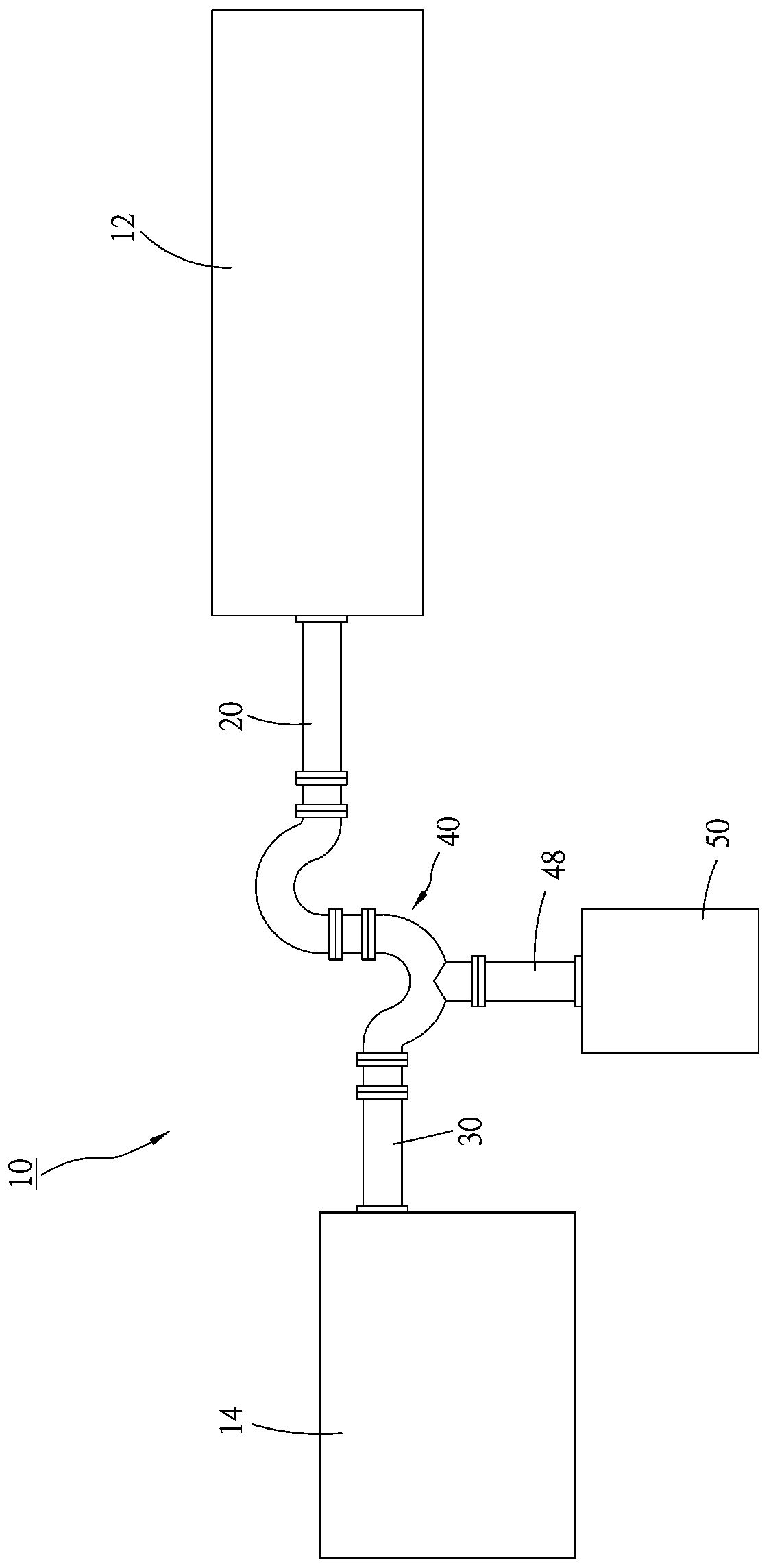

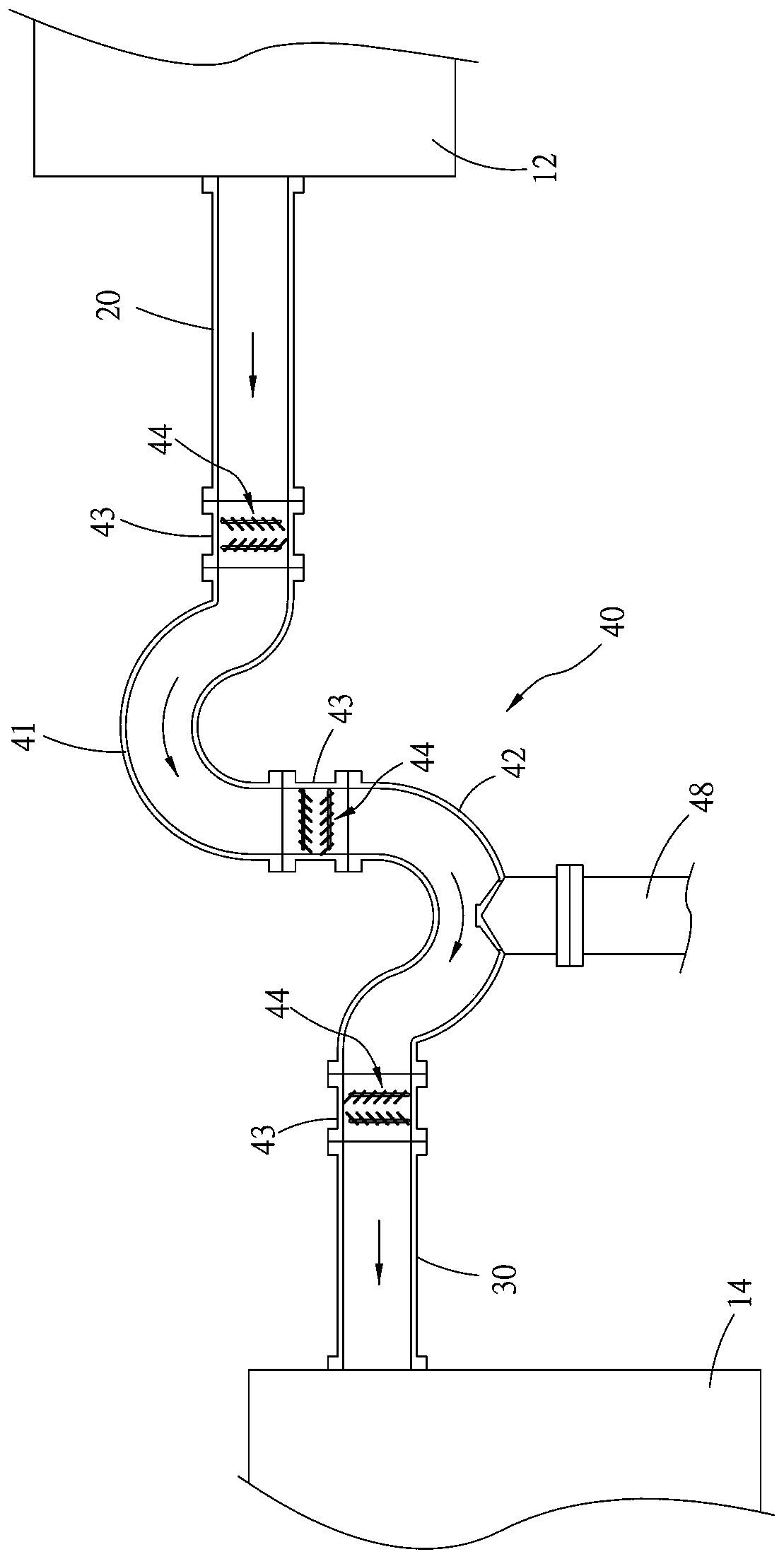

[0011] see figure 1 and 2 The condensing device 10 of the present invention is installed between a chamber 12 and a vacuum pump 14 of the vacuum coating equipment, and includes an inlet pipe 20 connecting the chamber 12, an outlet pipe 30 connecting the vacuum pump 14, and a gas outlet pipe 20 located at the inlet pipe 20. and the cold trap assembly 40 between the air outlet pipe 30.

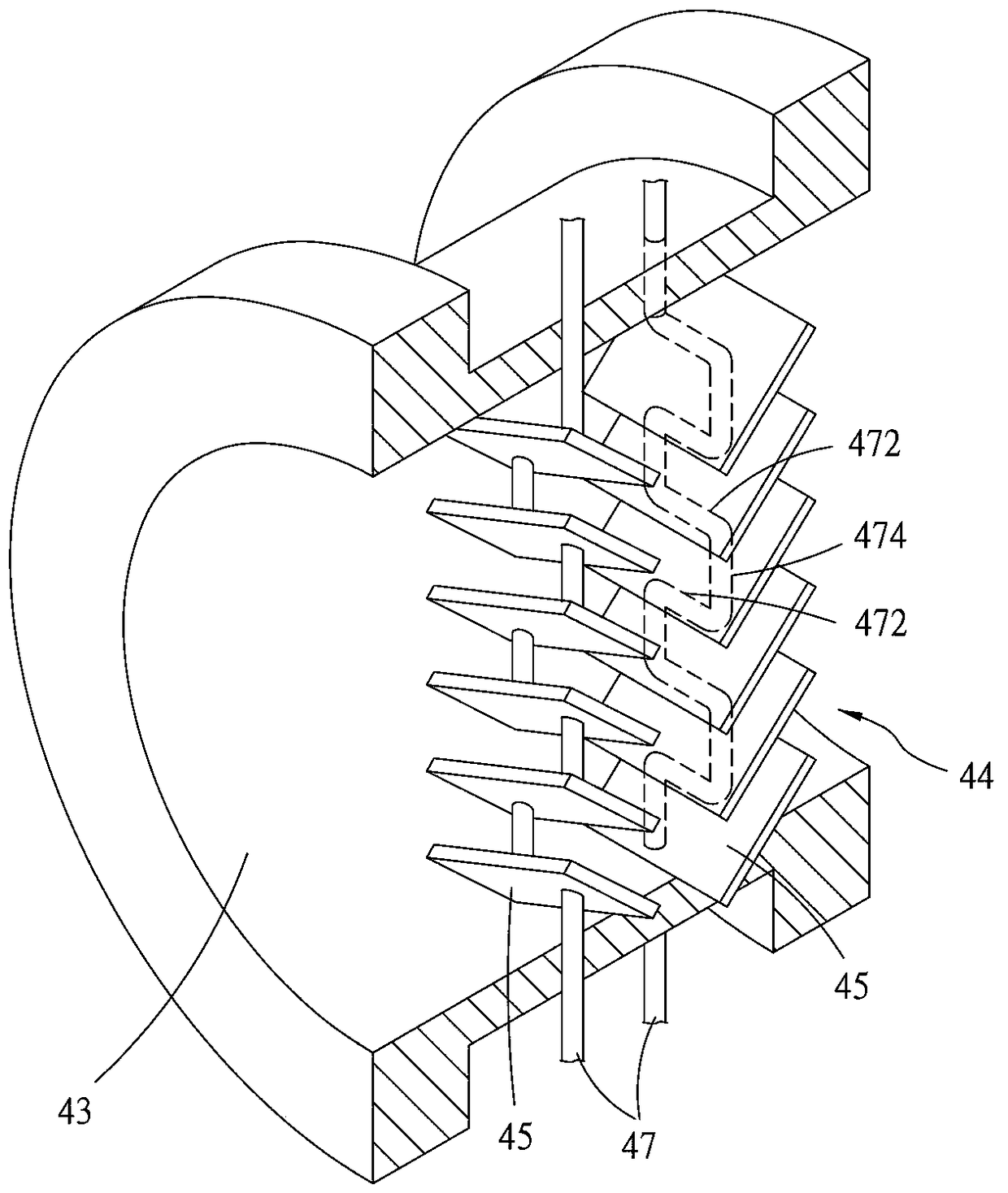

[0012] The cold trap assembly 40 has a first curved pipe 41 and a second curved pipe 42 . Between the first curved pipe 41 and the inlet pipe 20, between the first and second curved pipes 41, 42, and between the second curved pipe 42 and the air outlet pipe 30, there is a cold trap pipe respectively. 43 and connected two by two, and the first and second curved pipes 41, 42 have opposite bending directions, so that the first and second curved pipes 41, 42 form an S-shape after connection aisle. Furthermore, the cold trap assembly 40 has six baffle plate groups 44, and these baffle plate group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com