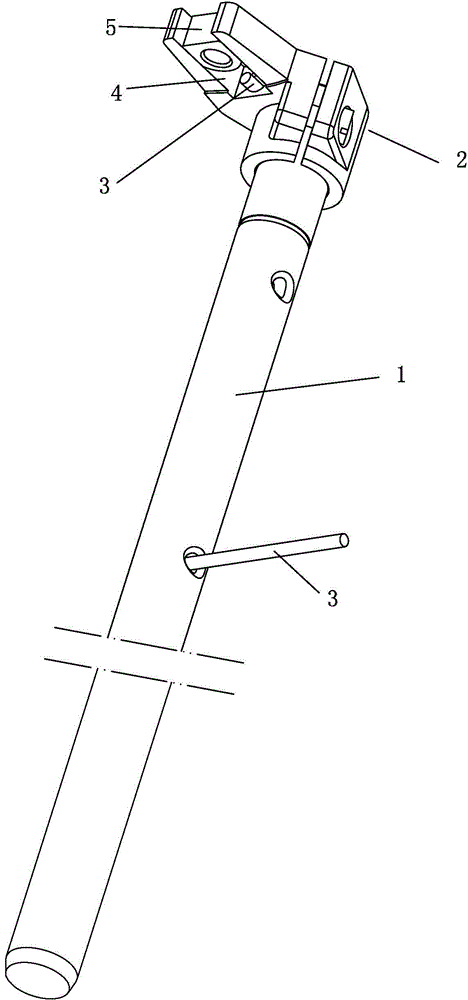

Modified forked feed lifting rock shaft crank

A fork-shaped and crank technology is applied in the field of improved fork-shaped tooth-lifting cranks, which can solve the problems of inconvenient processing and complex structure, and achieve the effects of low cost, simple processing technology and simplified structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

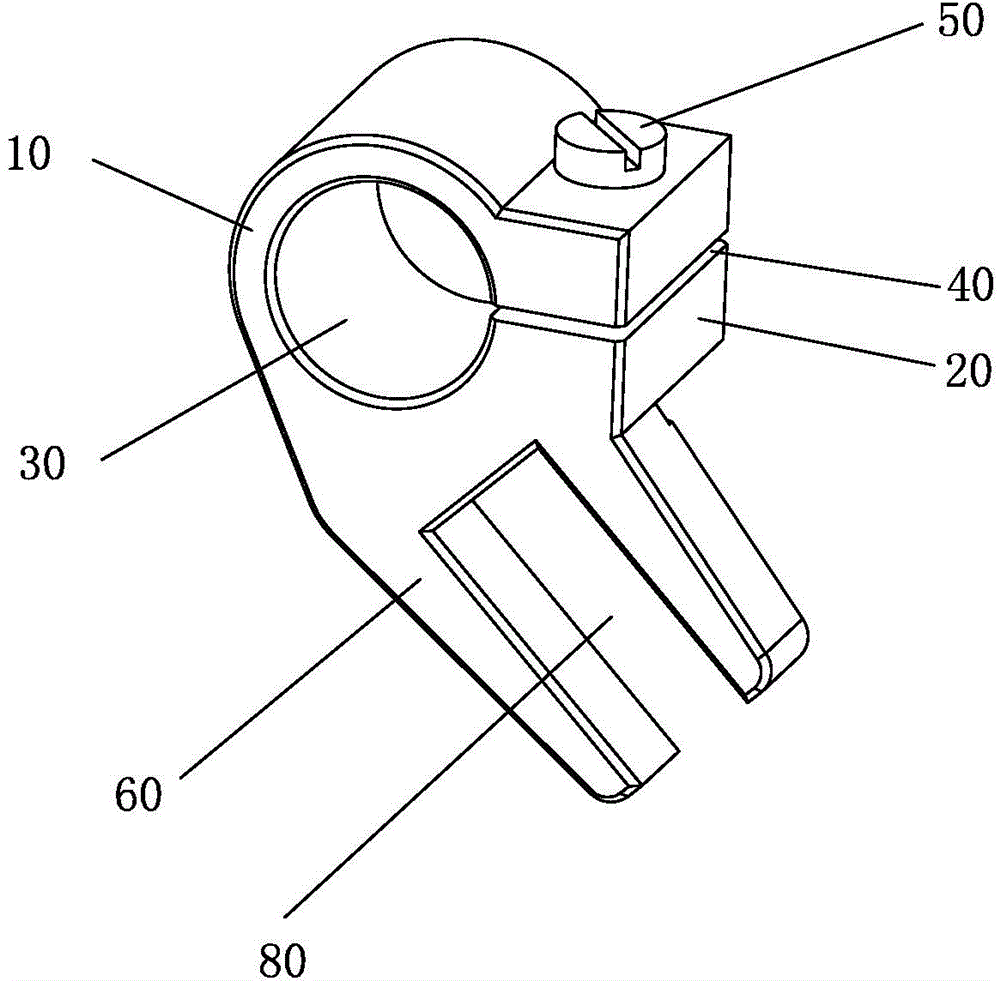

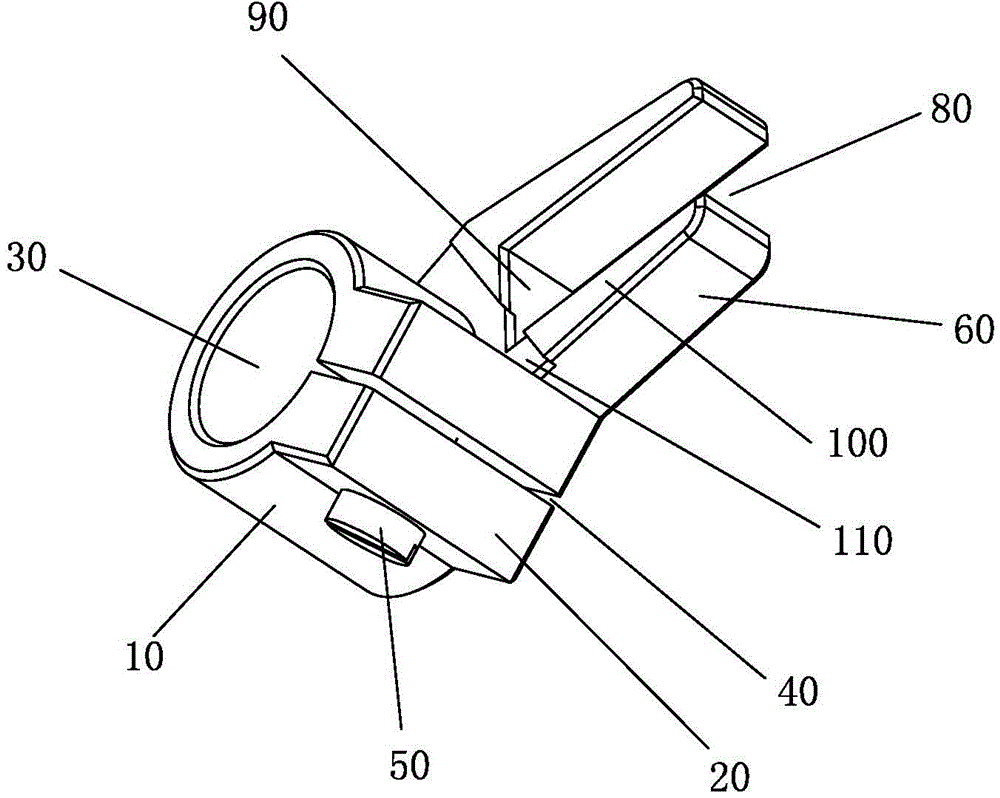

[0025] The present invention will be further described below with specific embodiment, see figure 2 —3:

[0026] An improved fork-shaped tooth-lifting crank, a protrusion 20 is axially provided on one side of the outer cylindrical surface of the cylinder 10, and an opening 40 communicating with the central hole 30 of the cylinder 10 is arranged on the protrusion 20. 20 is provided with a fastening screw 50 passing through the opening 40, and a fork-shaped plate 60 is arranged radially on the cylinder 10 on one side of the protrusion 20. The fork-shaped plate 60 includes a fork 80 for setting the slider 70, The bottom 90 of the fork 80 is a solid body, and the cylinder body 10, the bump 20 and the fork-shaped plate 60 are made of oil-containing powder metallurgy.

[0027] A side surface of the above-mentioned fork-shaped plate 60 close to the protruding block 20 is a stepped surface, and the plane 100 on the outside of the stepped surface is lower than the plane 110 on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com