Energy-saving phase gear torsion increasing device for engine

A phase gear and energy-saving device technology, which is applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of no air guide function, loss of air intake, large work power, etc., and achieve low fuel power and mechanical efficiency The effect of improving and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

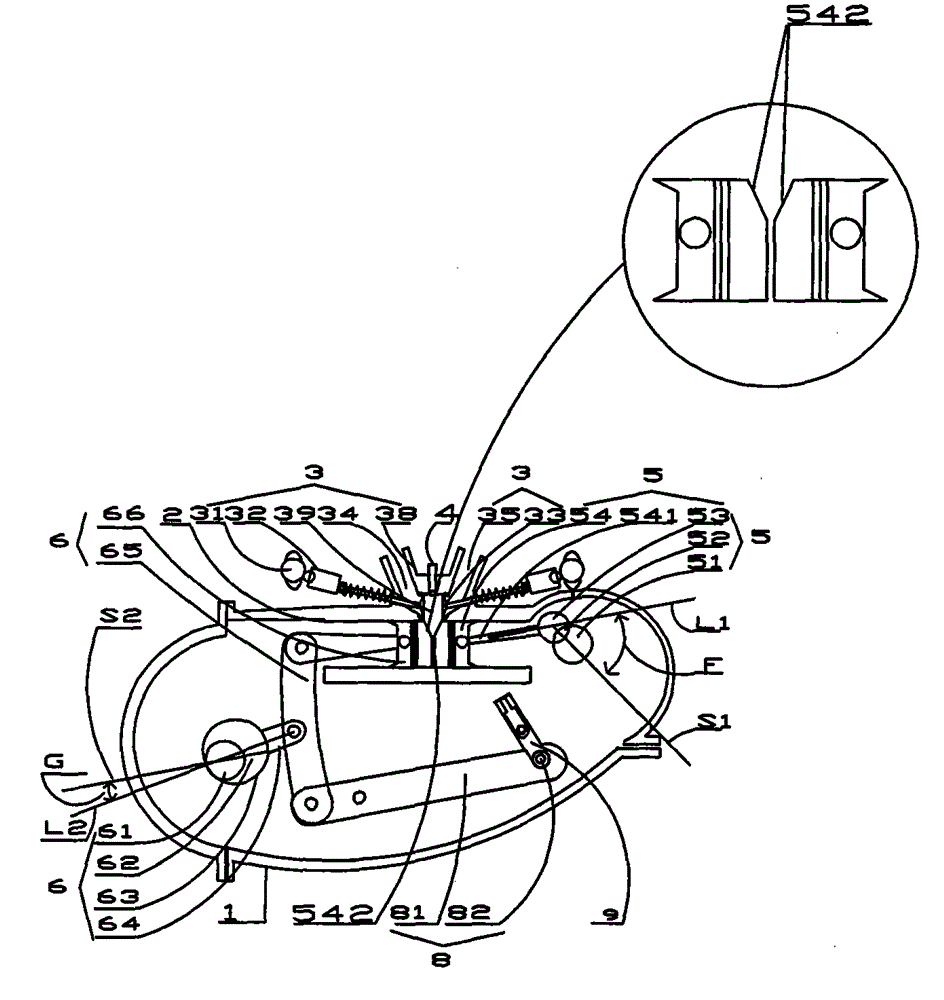

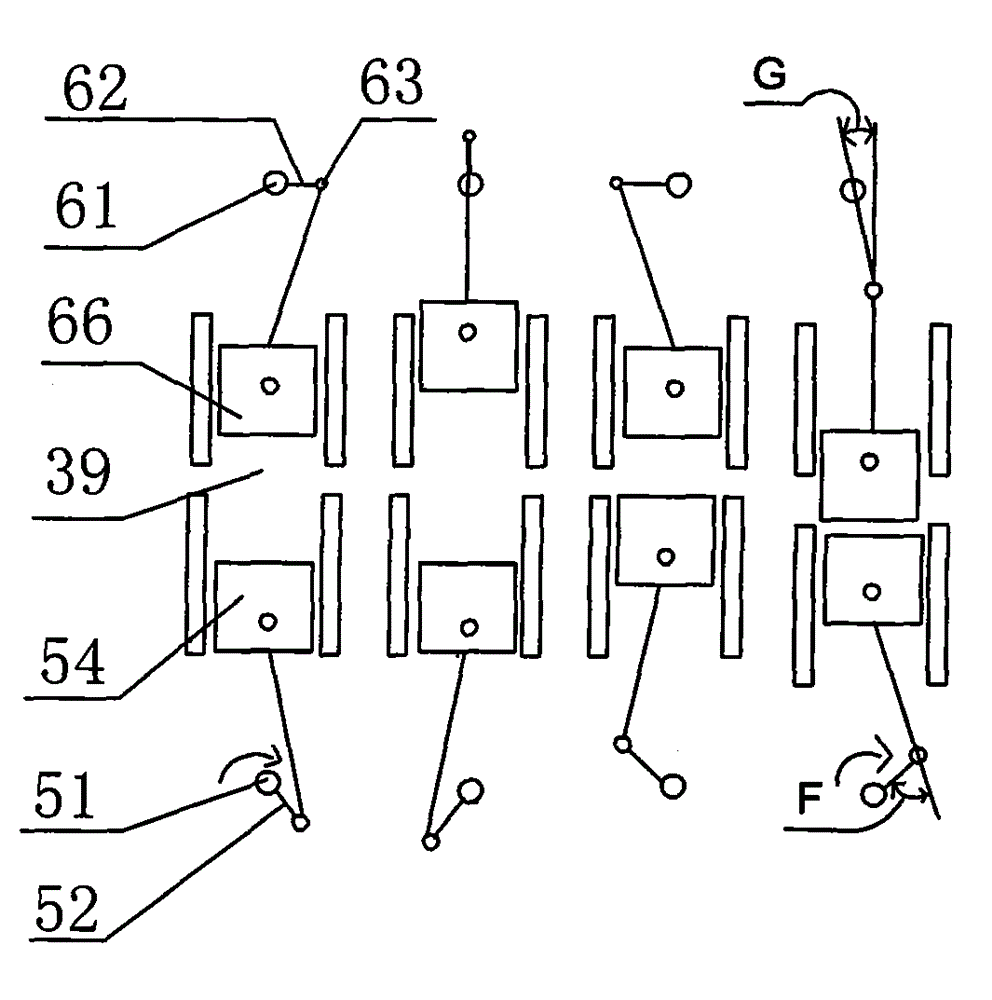

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

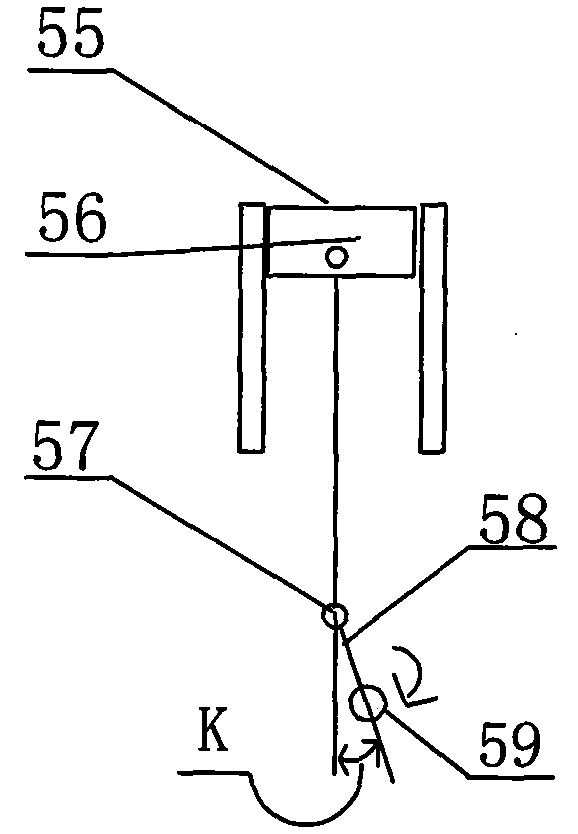

[0031] Such as Figure 2-Figure 4 Shown, a kind of engine phase gear is used to increase the torque energy-saving device, comprising body 1, cylinder 2, intake and exhaust valve mechanism 3, crankshaft air guide piston linkage 5, crankshaft air guide piston acceleration arm linkage 6, and The ignition mechanism 4, the ignition mechanism 4 can be a fuel nozzle or a spark plug or a fuel nozzle and a spark plug which are more commonly used at present, or compression ignition without ignition. The crankshaft gas pilot piston connecting rod mechanism 5 and the crankshaft gas pilot piston accelerating arm connecting rod mechanism 6 are respectively connected with the intermeshing phase gear 7 through shafts to ensure the crankshaft gas pilot piston connecting rod mechanism 5 and the crankshaft accelerating arm connecting rod mechanism 6 to opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com