Wet clutch

A wet clutch and clutch technology, applied in the field of clutches, can solve the problems of long clutch disengagement time, unstable clutch combination, easy damage to the sealing ring, etc., so as to simplify the design and processing technology, simplify the installation and assembly technology, and improve the sealing area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

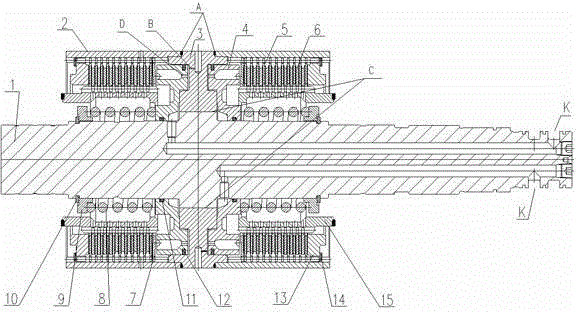

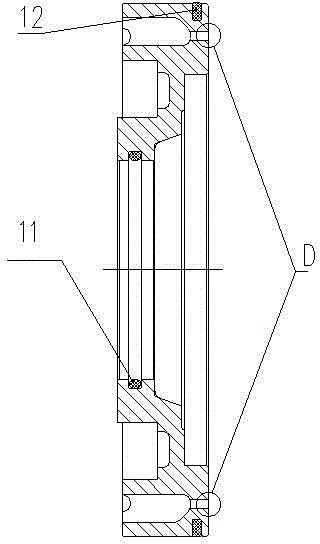

[0022] As shown in the figure, a wet clutch includes a main shaft 1, a clutch piston cylinder 3, a clutch outer hub 2 and a clutch inner hub 15. The clutch piston cylinder 3 is fixedly connected to the main shaft 1. In order to ensure the reliability of the connection, increase the To transmit torque, simplify the design and processing technology, reduce the production cost and simplify the installation and assembly process, this embodiment adopts taper interference fit connection, and the taper can be any one of 1:10~1:50.

[0023] The clutch outer hub 2 is fixedly connected to the clutch piston cylinder 3. In this embodiment, the clutch outer hub 2 and the clutch piston cylinder 3 are fixedly connected by laser welding. The laser welding method can minimize the deformation of the clutch hub, and improve production efficiency and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com