Self-adaptive follow-up device for open type grating reading head

A technology of a grating reading head and a follow-up device, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problem of reducing dimensional tolerances and shape and position tolerances, difficult to automatically adjust the grating reading head, and difficult to adapt to external factors. Changes and automatic adjustment and other problems, to achieve the requirements of reducing dimensional tolerances and geometric tolerances, the effect of safe and stable movement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with specific implementation examples.

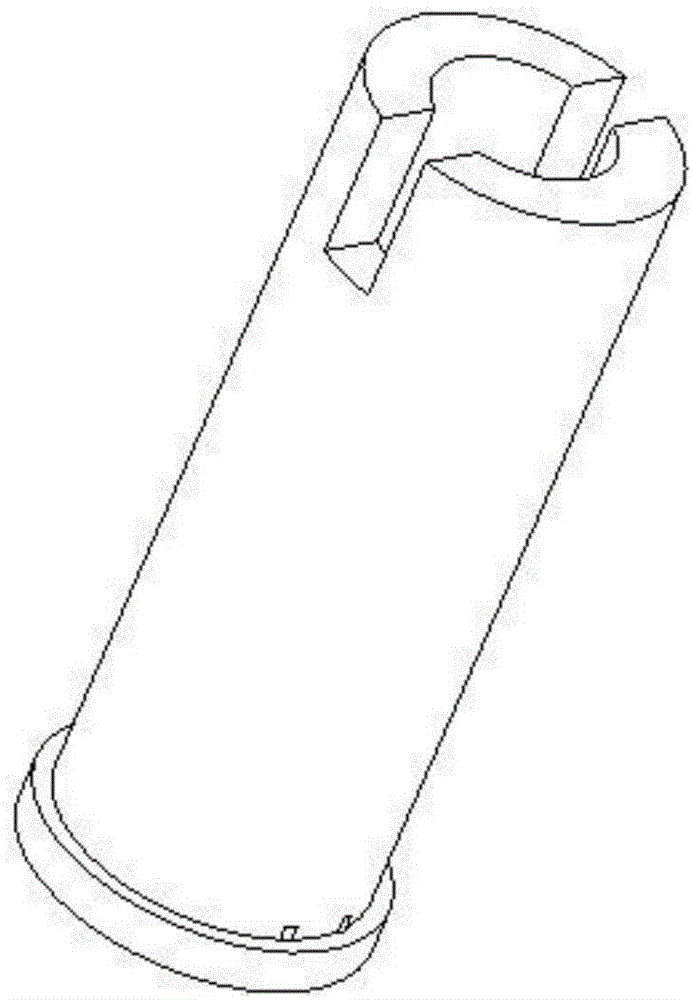

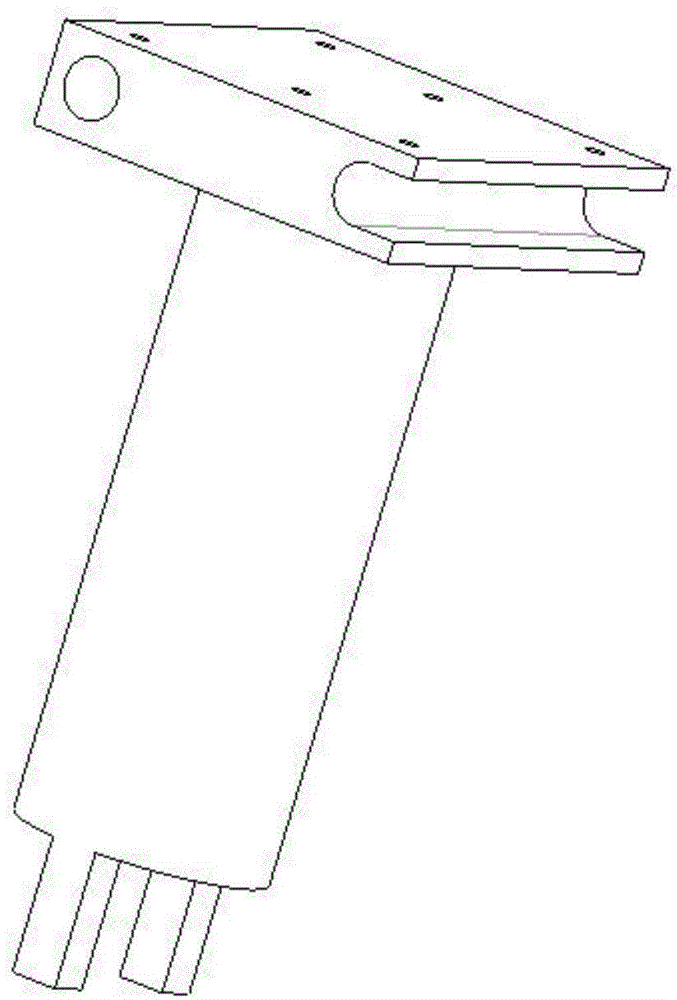

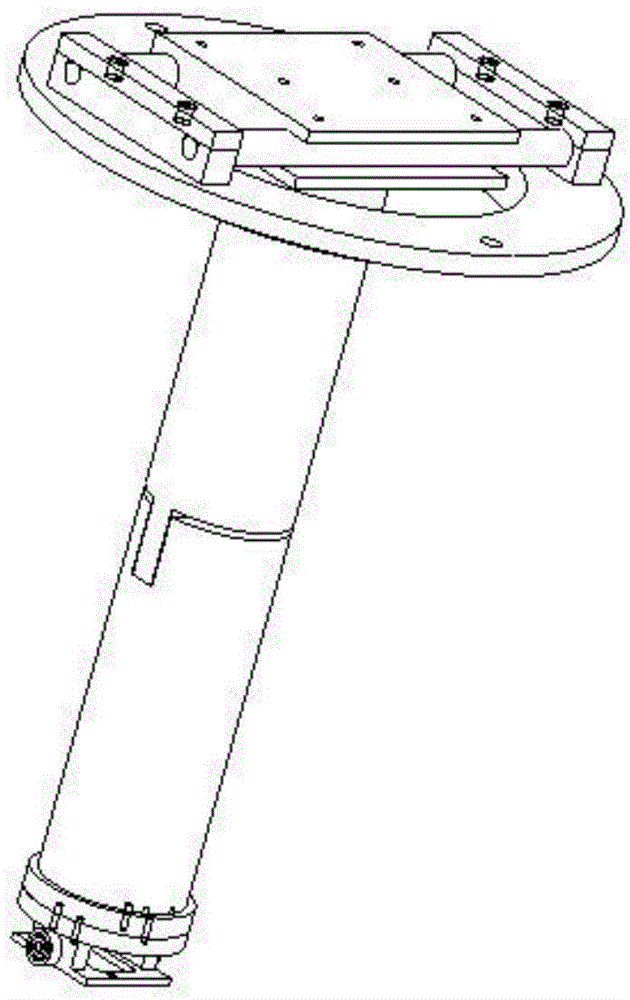

[0022] 1. see Figure 3-Figure 6 , the present invention designs an adaptive servo device for an open grating reading head, including a roller 2, a roller shaft 3, a reading head bracket 4, a bracket connection plate 5, a grating reading head 6, a guide sleeve 9, a retaining ring 10, Guide column 11, spring 13, anti-rotation sliding shaft 14, guide bar support seat 16, reading head protective cover 17, guide bar pressing plate 19, guide bar 23, etc.; On the head bracket 4, the roller 2 and the roller shaft 3 are installed on the reading head bracket 4, the bracket connecting plate 5 is fixed on the reading head bracket 4 by screws 8, and the guide sleeve 9 is fixed on the bracket connecting plate 5 by screws 12. The retaining ring 10 is installed between the guide sleeve 9 and the guide post 11, and steel balls are installed in the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com