Probe Holder for Modular Scanning Probe Microscopes

A scanning probe and microscope technology, applied in the field of scanning probe testing, can solve the problems of lack of precise positioning and clamping structure, affecting the clamping effect of the probe, changing the scanning area of the sample, etc., achieving good clamping effect and improving test accuracy And test efficiency, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

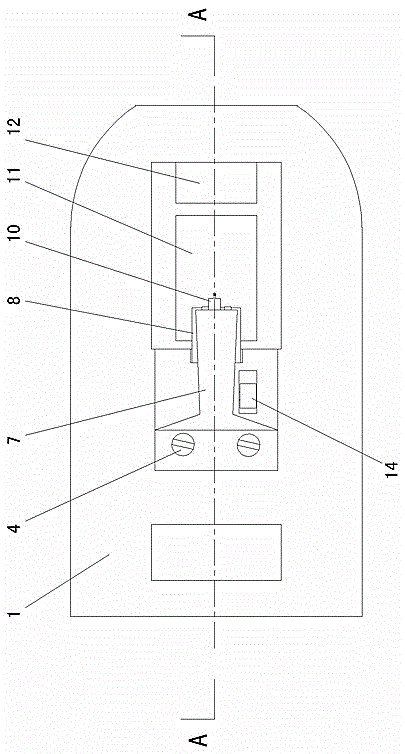

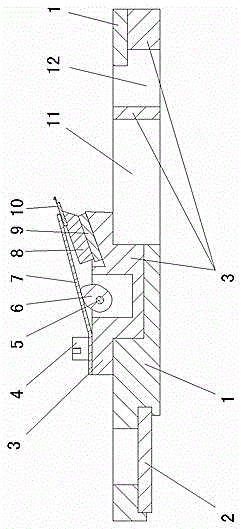

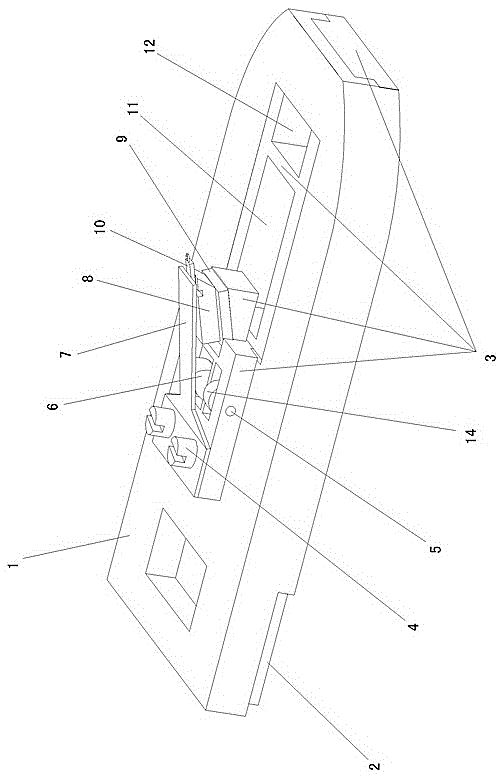

[0018] Such as figure 1 , 2 , shown in 3: 1 support, there is circuit board 2 at one end of support 1, between circuit board 2 and support 1 is the slot-type connection structure, promptly is processed with the slot that coincides with circuit board 2 on support 1, The circuit board 2 can be inserted from the side of the bracket 1 .

[0019] On the bracket 1, there is a clamping frame 3 for installing the probe 10, and the connection between the clamping frame 3 and the bracket 1 is a slot type, that is, the gap between the clamping frame 3 and the bracket 1 is split and the clamping frame 3 is inserted Inside the bracket 1 , the clamping frame 3 and the bracket 1 form a mosaic structure. There is a hollow on the bracket 1, and a signal window 11 for transmitting signals such as laser light and a hand-held frame 12 for easy installation and removal are provided on the clamping frame 3. The signal window 11 and the hand-held frame 12 are just located at the aforementioned hol...

Embodiment 2

[0025] Such as Figure 6 As shown: 1 bracket, there is a circuit board 2 at one end of the bracket 1, and the connection structure between the circuit board 2 and the bracket 1 is a slot type connection structure, that is, a slot matching the circuit board 2 is processed on the bracket 1, and the circuit board 2 Insert it from the side of bracket 1. On the bracket 1, there is a clamping frame 3 for installing the probe 10, and the connection between the clamping frame 3 and the bracket 1 is a slot type, that is, the gap between the clamping frame 3 and the bracket 1 is split and the clamping frame 3 is inserted Inside the bracket 3 , the clamping frame 3 and the bracket 1 form a mosaic structure. A hand-held frame 12 for easy installation and removal is provided on the clamping frame 3 . Probe installation holes 23 are processed on the holder frame 3 . The probe frame for a modular scanning probe microscope of the invention is suitable for a scanning tunneling microscope. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com