Magnetic sensing device and sensing method and preparation technology thereof

A preparation process and magnetic sensing technology, which are applied in the manufacture/processing of electromagnetic devices, measurement devices, and resistors controlled by magnetic fields, etc., can solve the problem of inability to manufacture triaxial sensors at the same time, and achieve obvious price competitiveness and excellent The effect of performance, good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

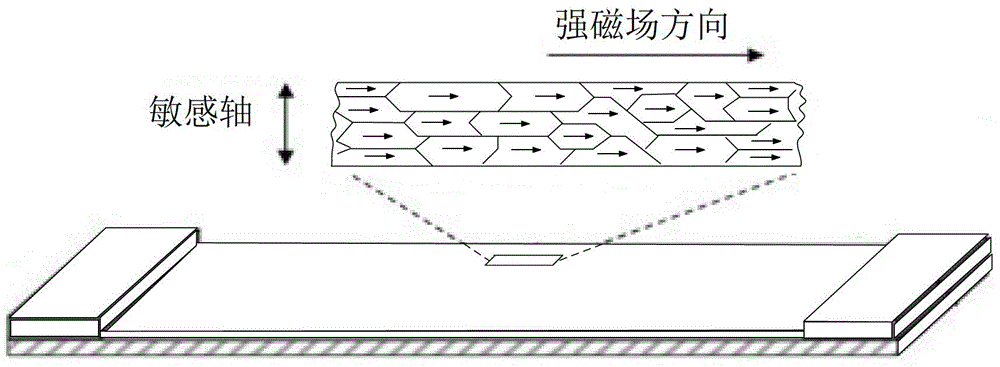

[0065] see Figure 6 , Figure 7 , the present invention discloses a magnetic sensing device, the magnetic material is perpendicular to the surface of the substrate (the angle between the substrate and the substrate is not strictly 90 degrees, which can be between 60 degrees and 90 degrees), so the Z-axis can be sensed direction, the magnetic sensing device includes: a substrate 100, a first electrode layer, a groove 130, a magnetic material layer 120, connection vias, connection wires, a pressurization module, and a magnetic field measurement module.

[0066] The first electrode layer is disposed on the substrate 100, including n first electrodes, where n is an integer; the first electrode layer is the electrode E1 in turn. 0 , Electrode E1 1 , Electrode E1 2 , ..., electrode E1 n-1 . In this embodiment, n=3, and the first electrode layer includes first electrodes 101 , 102 , and 103 arranged at equal intervals; of course, the distance between adjacent first electrodes m...

Embodiment 2

[0087] see Figure 15 , Figure 16 The difference between this embodiment and Embodiment 1 is that, in this embodiment, the magnetic material layer is deposited on both sides of the one trench.

[0088] The advantage of this embodiment is that both sides of the trench are used, which improves the efficiency of the substrate, increases the density of the device, and is beneficial to reduce the cost per unit area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com