Magnetic sensing device and manufacturing technology thereof

A preparation process and magnetic sensing technology, applied in the field of magnetic sensing, can solve the problems of inability to manufacture triaxial sensors at the same time, poor sensitivity, complex triaxial magnetic sensor preparation process, etc., to achieve obvious price competitiveness and improve sensitivity , the effect of good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

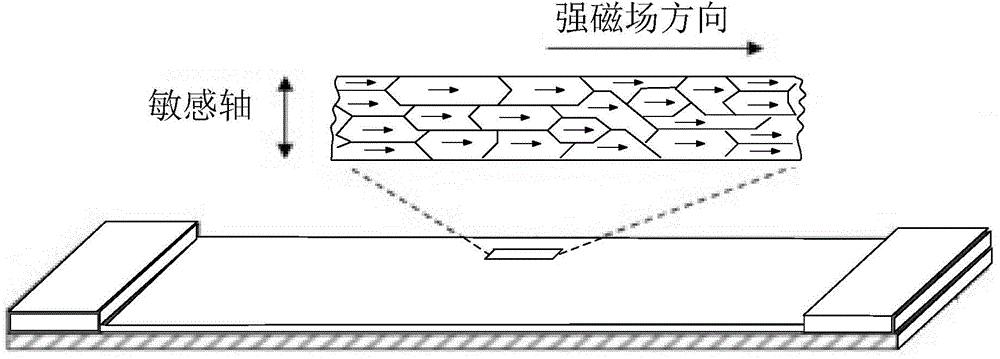

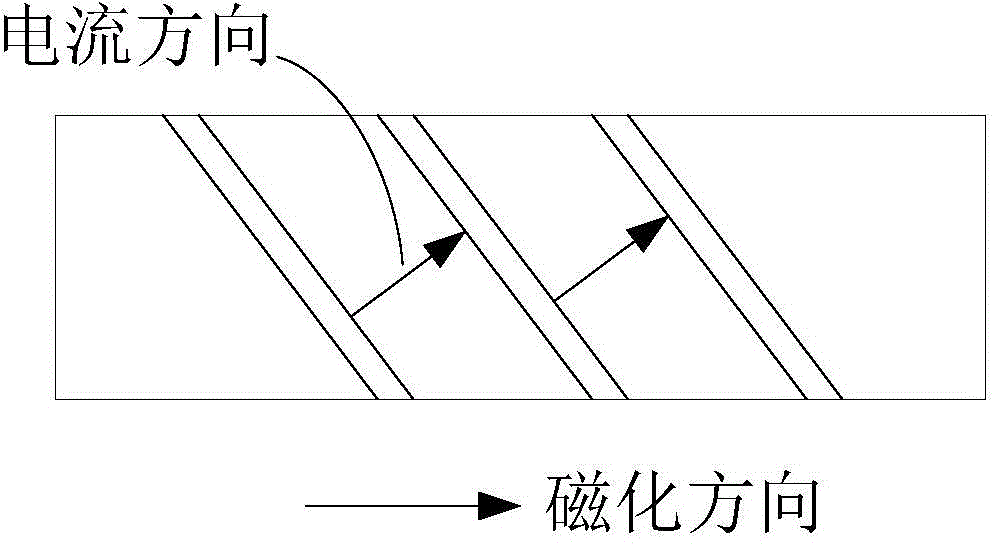

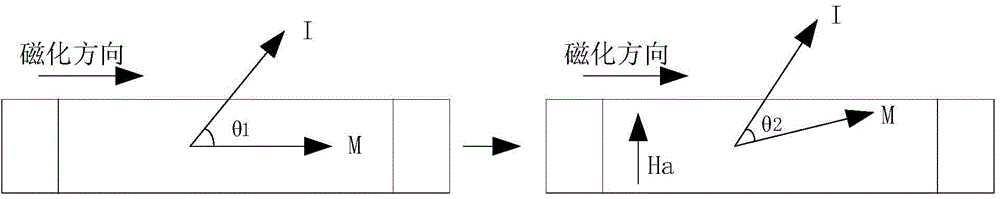

[0056] see Figure 9 , Figure 10 , the present invention discloses a magnetic sensing device, the device includes a vertical direction (as the third direction, of course, it can also be other third directions) magnetic sensing components, the vertical direction magnetic sensing components include: a substrate, a first A dielectric layer 10 , a second dielectric layer 20 , a magnetic conduction unit 31 , an induction unit 32 , and protective material layers 41 and 42 . Of course, the second dielectric layer 20 may not be provided, and the sensing unit 32 may be provided directly on the first dielectric layer 10; the first dielectric layer 10 and the second dielectric layer 20 may also be regarded as a part of the substrate.

[0057] The first dielectric layer 10 is arranged on the surface of the substrate, and groove groups are arranged on it, and one group of groove groups includes a plurality of grooves 11 arranged in parallel (such as Figure 9 As shown, a set of groove g...

Embodiment 2

[0074] In this embodiment, the magnetic sensing device includes a third directional magnetic sensing component, and the third directional magnetic sensing component includes: a substrate, a magnetic conduction unit, and an induction unit.

[0075] Groove groups are formed on the surface of the base, and a group of groove groups includes several parallel grooves. Part of the magnetic conduction unit is arranged in several grooves of the groove group, and part of the groove is exposed to the surface of the substrate, and the magnetic conduction units arranged in adjacent grooves in a groove group are connected; the magnetic conduction unit is used The magnetic signal in the third direction is sensed, and the magnetic signal is output to the sensing unit for measurement. The induction unit is arranged on one side of the corresponding groove group, and there is a gap between the magnetic conduction unit; the induction unit measures the magnetic field in the first direction or / and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com