Magnetic sensing device, and magnetic sensing method and manufacturing technology thereof

A magnetic sensing and magnetic sensor technology, applied in the field of electronic communication, can solve the problems that the three-axis sensor cannot be manufactured at the same time, and achieve the effect of obvious price competitiveness, excellent performance and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

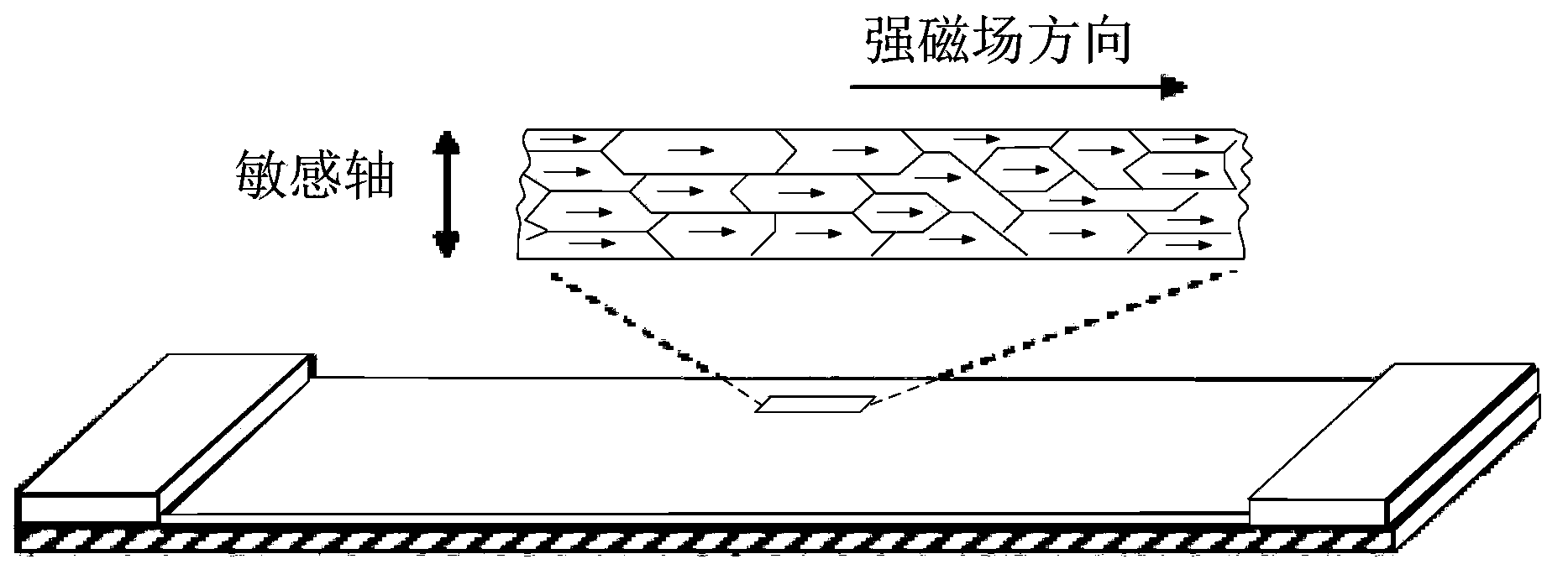

[0064] see Image 6 , Figure 7 ,in, Figure 7 Yes Image 6 The projection along the A-A direction; the present invention discloses a magnetic sensing device, which includes a Z-axis magnetic sensing component, and the Z-axis magnetic sensing component includes: a base 10, a magnetic conduction unit 20, and an induction unit; the base 10 may include CMOS peripheral circuits.

[0065] The surface of the substrate 10 has a dielectric layer, and a groove 11 is opened in the dielectric layer. The substrate is provided with one row or several rows of grooves. In this embodiment, one row of grooves includes several sub-grooves 11 .

[0066] The main part of the magnetic conduction unit 20 is disposed in the groove 11 , and a part is exposed from the groove 11 to the surface of the substrate for collecting the magnetic signal along the Z-axis and outputting the magnetic signal to the sensing unit.

[0067] The induction unit is disposed on the surface of the base to receive the ...

Embodiment 2

[0085] The difference between this embodiment and Embodiment 1 is that in this embodiment, multiple magnetic permeable structures can share the same groove; please refer to Figure 9 The grooves 11 on the substrate 10 can be arranged in one or more rows, and one row of grooves 11 can be arranged as a long and narrow groove for shared use by multiple magnetic components.

[0086] In addition, in this structure, the magnetic conduction unit can be connected with the sensing unit, that is, the distance is 0um.

Embodiment 3

[0088] In this embodiment, the magnetic sensing device of the present invention further includes a CMOS chip, and the substrate described in Embodiment 1 is disposed on the CMOS chip. That is, the magnetic sensing device has the functions of the existing CMOS chip. That is to say, there are both CMOS chips and sensing devices on a single chip, which has a high degree of integration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com