Manufacturing technology of magnetic sensing device

A manufacturing process and magnetic sensing technology, applied in the manufacturing/processing of electromagnetic devices, measuring devices, measuring magnetic variables, etc., can solve the problem of not being able to manufacture three-axis sensors at the same time, and achieve obvious price competitiveness, excellent performance, The effect of good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

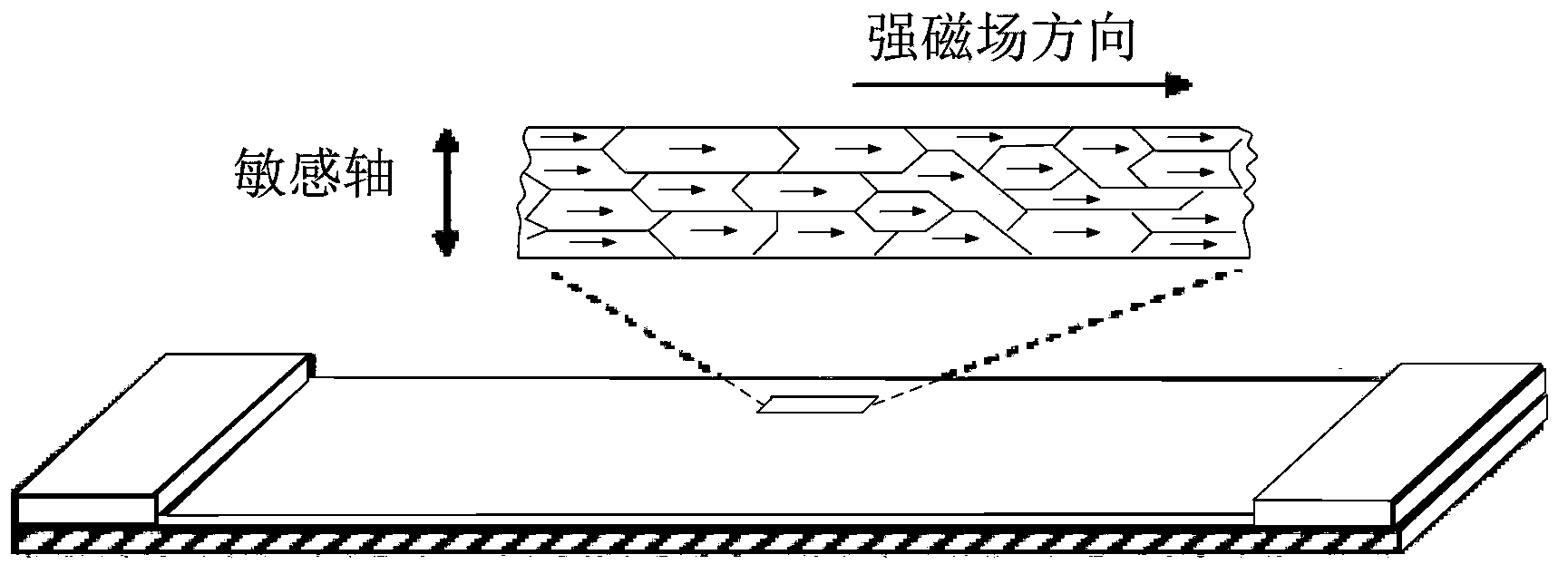

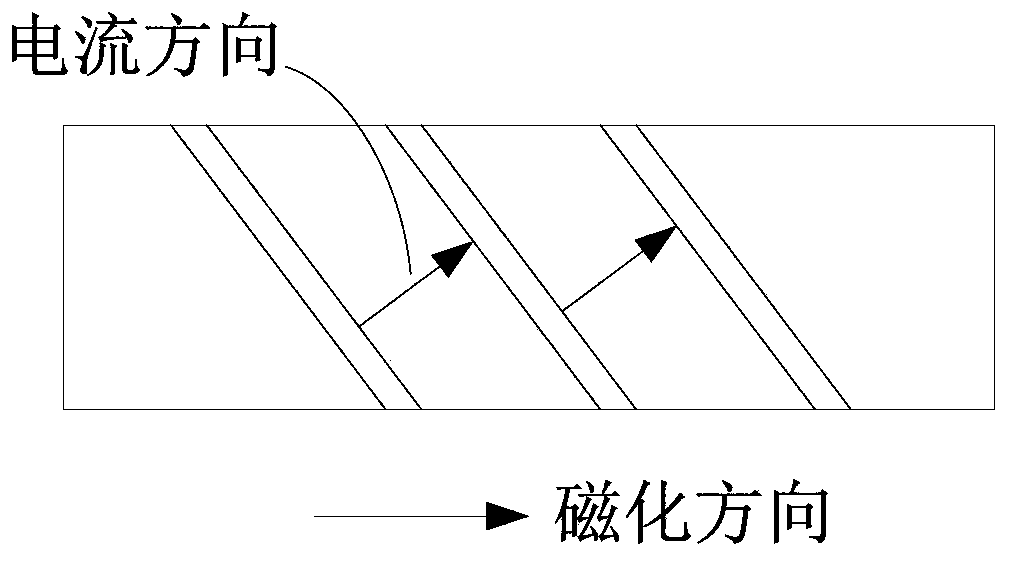

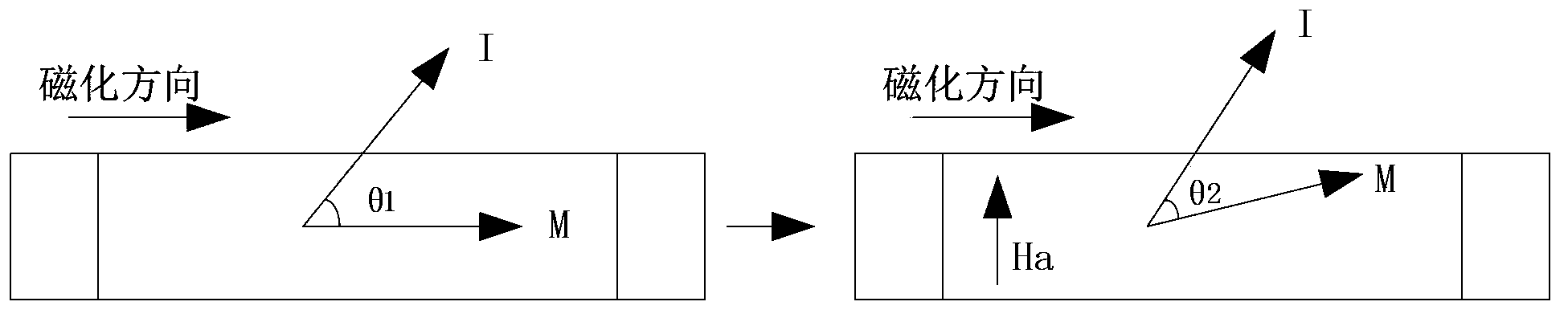

Method used

Image

Examples

Embodiment 1

[0069] see Image 6 , Figure 7 ,in, Figure 7 yes Image 6 The projection along the A-A direction; the present invention discloses a magnetic sensing device, which includes a Z-axis magnetic sensing component, and the Z-axis magnetic sensing component includes: a substrate 10, at least one pair of magnetic sensing devices that cooperate Module; the magnetic sensing module includes a magnetic conduction unit 20 and an induction unit. The substrate 10 may include CMOS peripheral circuits. After each pair of matching two magnetic sensing modules is set up, it can directly offset the magnetic field interference of each pair of magnetic sensing modules in the X-axis direction or / and Y-axis direction, and obtain a pure Z-axis signal, so there is no It needs to use peripheral circuits for signal processing, accurate measurement and high precision.

[0070] The surface of the substrate 10 has a dielectric layer, and a groove 11 is opened in the dielectric layer. The substrate i...

Embodiment 2

[0105] see Figure 10 The difference between this embodiment and Embodiment 1 is that in this embodiment, the third direction magnetic sensing component includes a first magnetic sensing module 101, a second magnetic sensing module 102, and a third magnetic sensing module 103 , the fourth magnetic sensing module 104 . The magnetic sensing modules are arranged in parallel, or the centers are on the same straight line; that is, the magnetization directions of the magnetic material layers of the sensing units in the magnetic sensing modules are the same or opposite, and the grooves of the magnetic sensing modules are parallel or coincident.

[0106] The first end of the first magnetic sensing module 101 and the first end of the second magnetic sensing module 102 are grounded, and the second end of the first magnetic sensing module 101 is connected to the first end of the fourth magnetic sensing module 104 , the second end of the second magnetic sensing module 102 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com