Linear quadratic fault-tolerant control method of batch process optimized by genetic algorithm

A genetic algorithm and linear quadratic technology, applied in the field of linear quadratic fault-tolerant control, can solve problems such as actuator failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Taking the control of injection speed in the injection molding process as an example

[0070] The control of injection speed in the injection molding process is a typical batch process, and the adjustment method is to control the opening of the proportional valve.

[0071] Step (1). Establish the extended state-space model of the injection process, the specific method is:

[0072] a. Establish a real-time operation database of the injection process, collect real-time process operation data through the data acquisition device, and use the collected real-time process operation data as a data-driven sample collection in, Indicates the opening degree of the i-th proportional valve, and y(i) indicates the actual output injection speed of the i-th group; based on the real-time process operation data set of the injection speed process, the local Controlled autoregressive moving average model:

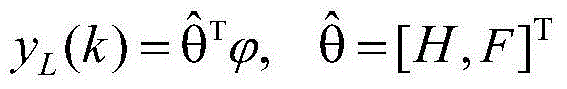

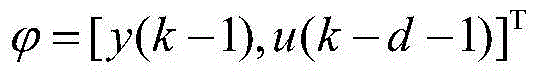

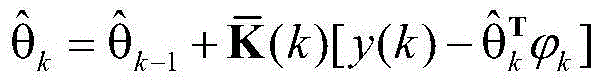

[0073]

[0074]

[0075] Among them, y L (k) represents the actual out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com