Three-phase transformer with built-in high-frequency inductor

A three-phase transformer and inductor technology, applied in the field of transformers, can solve the problems of large core loss, large inductor noise, and adverse effects of transformers, and achieve the effect of ensuring effective work and avoiding high-frequency loss and high-frequency noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described in conjunction with the following examples.

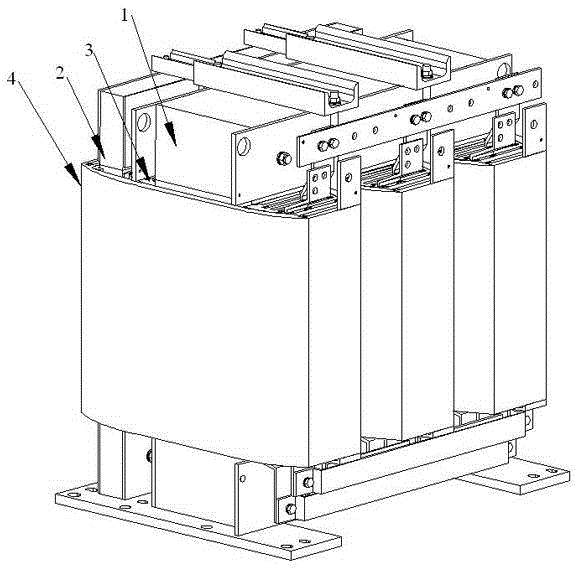

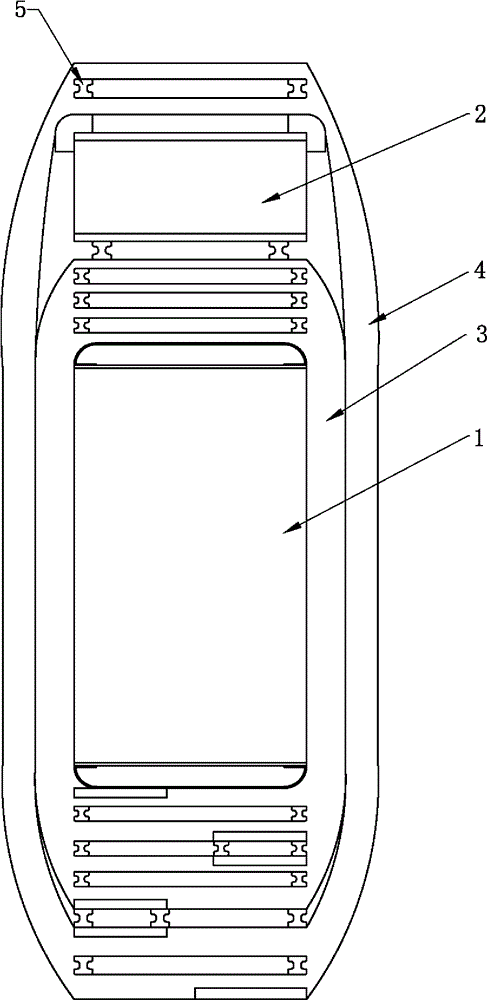

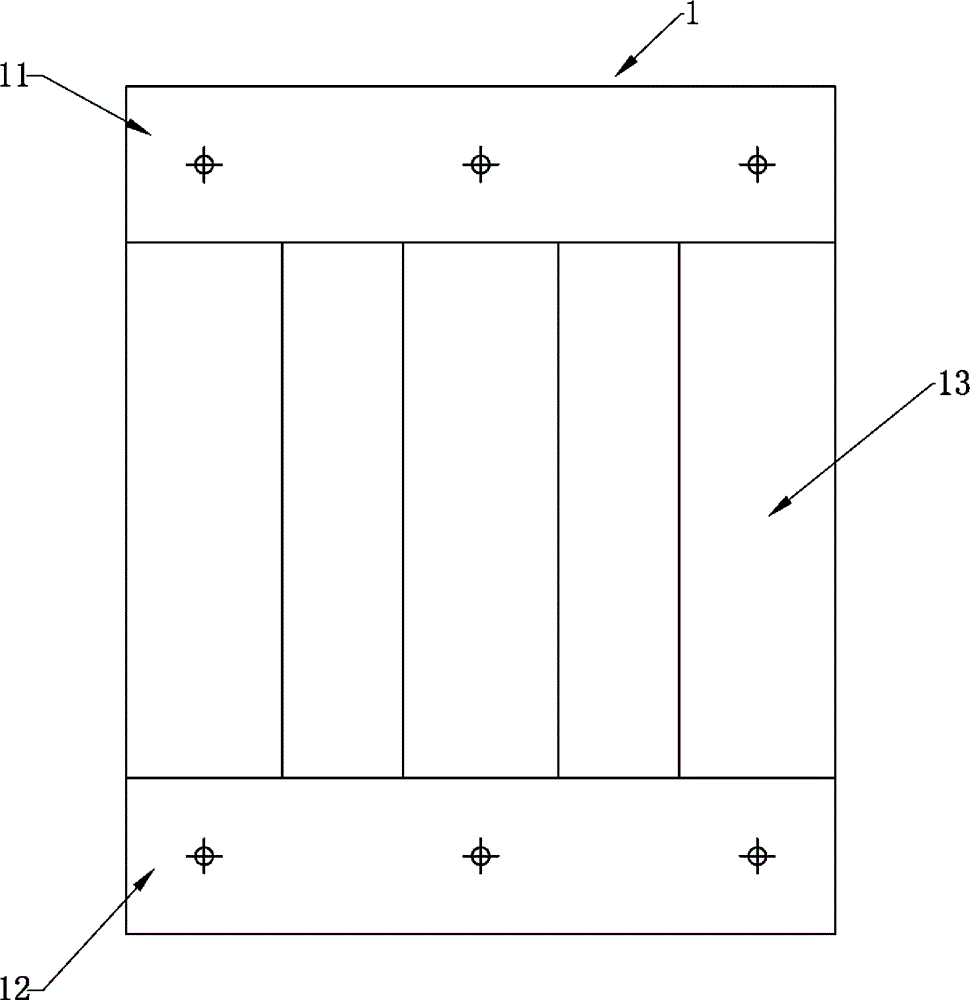

[0022] A specific embodiment of a transformer with a built-in high-frequency inductor in the present invention, such as Figure 1 to Figure 4 As shown, it includes: a main magnetic core 1 forming a main main magnetic flux circuit and a secondary magnetic core 2 forming a leakage magnetic flux circuit. The upper iron yoke 11 and the main lower iron yoke 12 fixed on the lower end of the main core column 13, the main core column 13, the main upper iron yoke 11 and the main lower iron yoke 12 are respectively laminated with silicon steel; the auxiliary magnetic core 2 It includes three auxiliary stems 23, an auxiliary upper iron yoke 21 fixed on the upper end of the auxiliary stem 23, and an auxiliary lower iron yoke 22 fixed on the lower end of the stem. The auxiliary stem 23 is composed of several uniform air gaps The columnar iron-silicon magnetic powder core 24 is spliced. The shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com