Earthing clamp device and operation method thereof

A technology of grounding wire clip and wire clip body, which is applied in the direction of electrical connection seat, clamping/spring connection, clip connection conductor connection, etc. It can solve the problems of difficult installation, scratches on wires, and affecting work efficiency, etc., to achieve protection and safety , Improve electrical conductivity and avoid hard collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

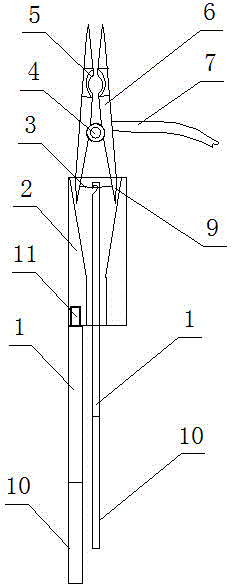

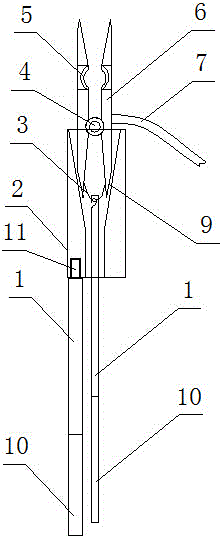

[0023] A grounding clamp device, including a clamp body and an operating mechanism, one side of the clamp body is welded or crimped with a ground wire 7 through bolts, and the clamp body includes a clamp body 6 hinged by a rotating shaft 4 and a strong spring , the front part of the clamp body 6 is provided with a groove for clamping the transmission line, a slot is provided in the groove, and the graphite layer 5 is snapped into the groove through the slot; the tail of the clamp body is The end is provided with a pull cord 3 connected between the clamp bodies 6. The operating mechanism includes two insulating operating rods 1, one of which is provided with a hook structure 8 at the top of the operating rod 1, and a metal screw 11 at the top of the other operating rod 1. , and the metal screw 11 is provided with a cylindrical member 2 with an inverted cone cavity structure inside, and a bolt hole is provided on one side of the cylindrical member 2, and the cylindrical member 2 ...

Embodiment 2

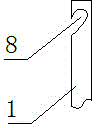

[0025] The difference between this embodiment and the first embodiment lies in that: the tail of the clamp body is provided with a slope structure 9 matching the cavity structure of the inverted cone. The operating rod 1 is a telescopic operating rod, including an inner rod and an outer tube. The outer tube is provided with a compression bolt, and the inner rod and the outer tube are reliably connected by the compression bolt through the outer tube wall to compress the inner rod. connect. The hook structure 8 at the top of the operating rod 1 is a groove structure opened on the side of the top of the operating rod 1 .

Embodiment 3

[0027] A method for performing operations using the grounding clamp device of the above-mentioned embodiment 1 or embodiment 2, comprising the following steps:

[0028] 1) According to the distance between the operator and the transmission line during the specific operation, and the length of the operating rod 1 and the extension rod 10, different numbers of insulating extension rods 10 are prepared, and the staff arrives at the crossarm where the transmission line to be repaired is located on the tower , through the transfer rope, the grounding wire clamp device and the electric inspection inductor are transferred to the work cross arm. An insulating operating rod 1 is connected to an electric inspection inductor on its metal screw rod 11, and an electric inspection is carried out on the power transmission line to be repaired to ensure that the line has no voltage;

[0029] 2) After the electric test is completed, remove the electric test sensor and replace the cylinder part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com