A kind of automatic assembly equipment for micro-motor rotor

An automatic assembly and micro-motor technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems that cannot be found in time, the quality of finished rotor products is unstable, and the production process is complicated, so as to achieve the control of scrap rate of finished products, reasonable design, Eliminates the effect of secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

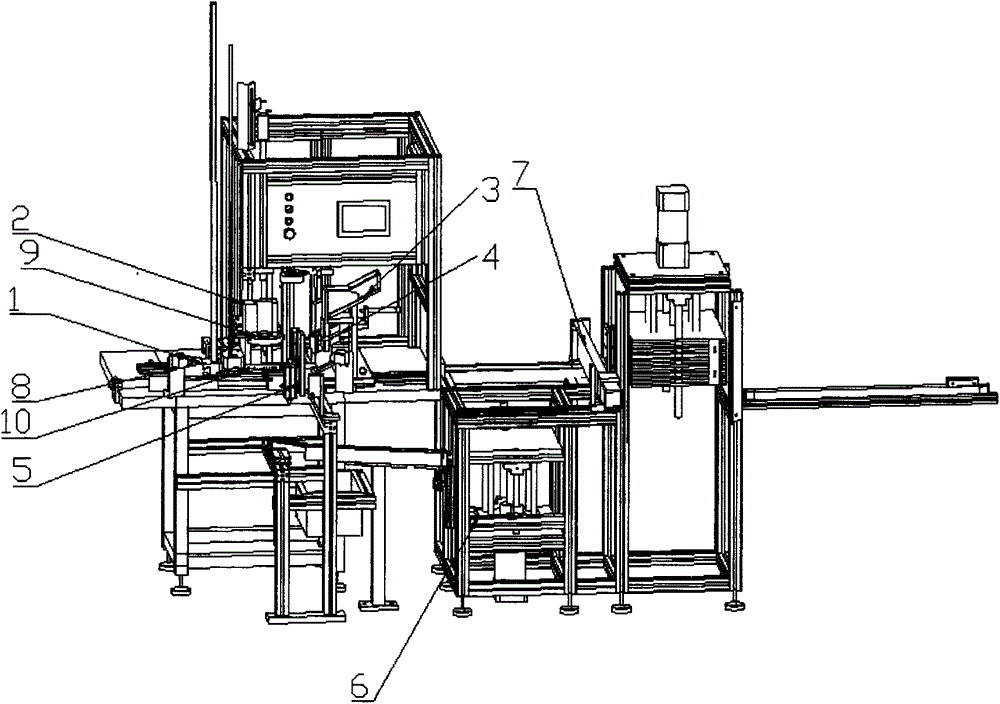

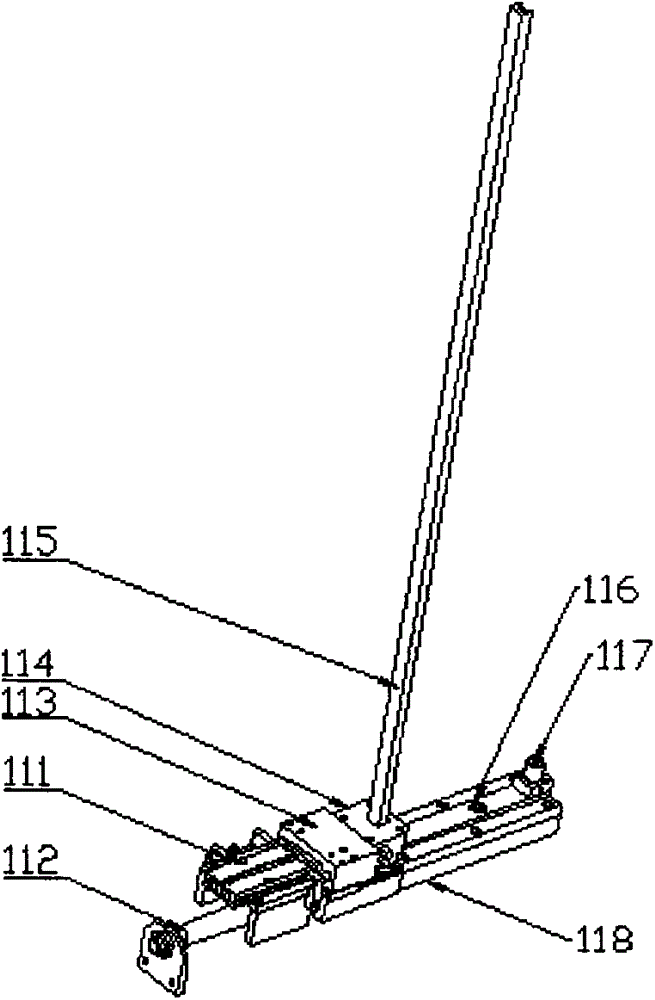

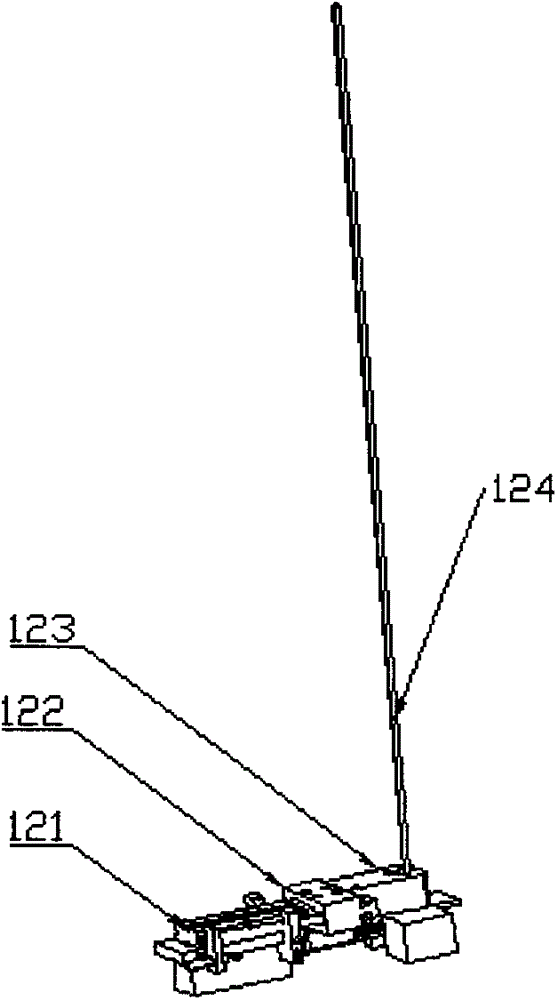

[0022] Such as Figure 1-8As shown, a micro motor rotor automatic assembly equipment includes a frame, the frame includes a first workbench and a second workbench, and the upper surface of the first workbench is provided with a pushing device 1 and an inverted shaft clamping device 4. The pushing device 1 includes a horizontal pushing mechanism 11 and a vertical pushing mechanism 12, and the vertical pushing mechanism 12 includes a third cylinder 121, a second fixing rod 124, a second lamination fixing plate 123 and a second The laminated bottom plate 122, the lower end of the second fixed rod 124 is fixed to the second laminated fixed plate 123, the side of the second laminated fixed plate 123 is connected to the second laminated bottom plate 122, the piston rod of the third cylinder 121 is connected to the The second lamination bottom plate 122 is connected, and the horizontal pushing mechanism 11 includes a first cylinder 111, a second cylinder 112, a first fixed rod 115, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com