Chromogenic composition, chromogenic curable composition, lithographic printing plate precursor, platemaking method, and chromogenic compound

A lithographic printing plate and composition technology, applied in the field of color-developing compositions, can solve the problems of insufficient visibility, high color-developing properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0375] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to these Examples. In addition, in a polymer compound, unless otherwise specified, the molecular weight is a mass average molar mass (Mw), and the ratio of a repeating unit is a molar percentage.

[0376] I. The synthetic method of specific compound of the present invention

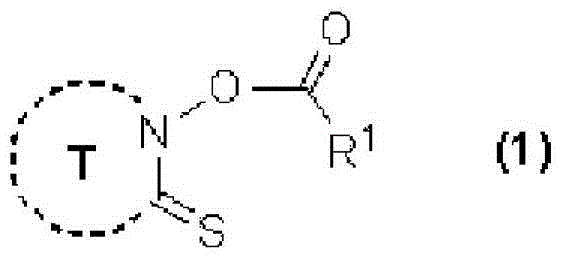

[0377] I-1. The synthetic method of intermediate (1)

[0378] [chem 23]

[0379]

[0380] COCl at room temperature for 30 min 2 (20 mass % toluene solution, 69.3g [140mmol]) and the solution of toluene 100g were added dropwise the solution of N-oxide (1) (8.25g [65mmol] and toluene 20g. After the dropwise addition, stirred for 30 minutes, and the resulting The precipitate was washed with toluene and then filtered to obtain 10.6 g [55.9 mmol] of intermediate (1). The yield was 86%.

[0381] The structure of the obtained intermediate 1 was identified by NMR. The identification results are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Centerline average roughness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com