Compound pig feed for reducing thickness of back fat by using appropriate energy nitrogen ratio of pig and preparation method thereof

A technology of compound feed and energy-to-nitrogen ratio, applied in the field of pig feed at 75-100kg, can solve problems such as affecting the economic benefits of farms, and achieve the effect of improving back fat thickness and creating economic value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

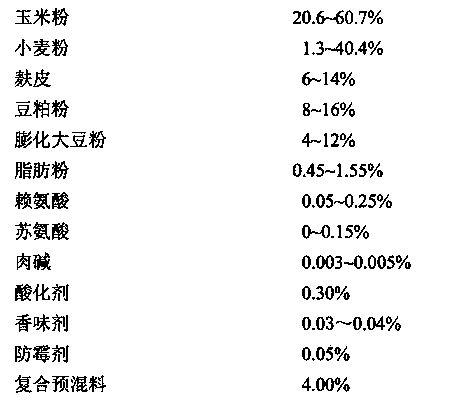

[0026] 1. The formula of a pig compound feed for reducing the thickness of backfat by using suitable energy-nitrogen ratio for pigs of the present invention is as follows:

[0027]

[0028] The above raw materials are all available in the raw material market.

[0029] 2. The preparation method of the above compound feed, the specific operation process steps are as follows:

[0030] (1) According to the formula, select the appropriate components as raw materials, formulate the composition according to the appropriate ratio, and calculate the energy-to-nitrogen ratio of the formulated composition, that is, the swine metabolizable energy (Mcal / kg): Porcine ileum really digestible lysine (%) = 2.18.

[0031] (2) Crushing: the corn flour and wheat flour in the composition are respectively crushed to 1.0-1.2 mm and 1.8-2.2 mm for use. Soybean meal and puffed soybean must be mixed and then crushed to 1.0-1.2 mm for use.

[0032] (3) Feeding and mixing: the above-mentioned corn flour, wheat fl...

Embodiment 2

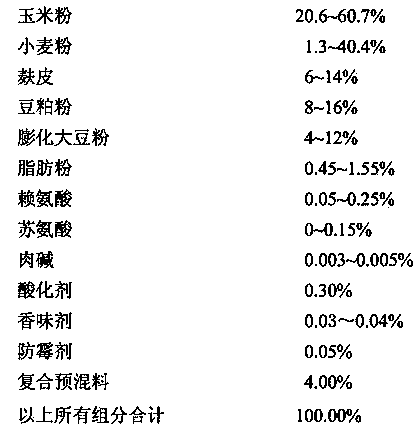

[0040] 1. The formula of a pig compound feed for reducing the thickness of backfat by using suitable energy-nitrogen ratio for pigs of the present invention is as follows:

[0041]

[0042]

[0043] The above raw materials are all available in the raw material market.

[0044] 2. The preparation method of the above compound feed, the specific operation process steps are as follows:

[0045] (1) According to the formula, select the appropriate components as raw materials, formulate the composition according to the appropriate ratio, and calculate the energy-to-nitrogen ratio of the formulated composition, that is, the swine metabolizable energy (Mcal / kg): Porcine ileum truly digestible lysine (%) = 2.05.

[0046] (2) Crushing: the corn flour and wheat flour in the composition are respectively crushed to 1.0-1.2 mm and 1.8-2.2 mm for use. Soybean meal and puffed soybean must be mixed and then crushed to 1.0-1.2 mm for use.

[0047] (3) Feeding and mixing: the above-mentioned corn flour, ...

Embodiment 3

[0055] 1. The formula of a pig compound feed for reducing the thickness of backfat by using suitable energy-nitrogen ratio for pigs of the present invention is as follows:

[0056]

[0057]

[0058] The above raw materials are all available in the raw material market.

[0059] 2. The preparation method of the above compound feed, the specific operation process steps are as follows:

[0060] (1) According to the formula, select the appropriate components as raw materials, formulate the composition according to the appropriate ratio, and calculate the energy-to-nitrogen ratio of the formulated composition, that is, the swine metabolizable energy (Mcal / kg): Porcine ileum is really digestible lysine (%) = 2.22.

[0061] (2) Crushing: the corn flour and wheat flour in the composition are respectively crushed to 1.0-1.2 mm and 1.8-2.2 mm for use. Soybean meal and puffed soybean must be mixed and then crushed to 1.0-1.2 mm for use.

[0062] (3) Feeding and mixing: the above-mentioned corn flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com