Slag treatment process

A technology for treating process and slag, applied in the direction of solid waste removal, etc., can solve problems affecting human health, land pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings and examples.

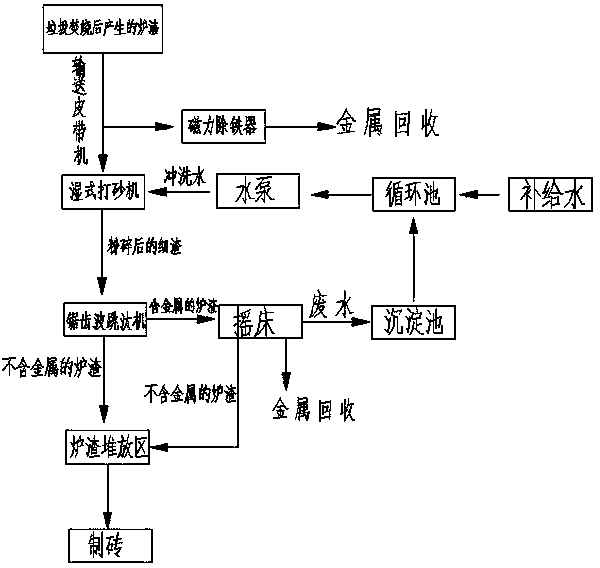

[0011] The invention is a slag treatment process, which is specially used for the treatment process of slag produced after domestic waste incineration. The process flow of the treatment method is as follows: figure 1 Shown:

[0012] First of all, the slag produced after the incineration of domestic waste is sent to the wet sand making machine through the belt conveyor, and the wet sand making machine will fully break up hard substances such as sintered slag blocks, stones or concrete blocks below 100 mm in the slag. into fine slag, a magnetic separator is installed above the belt conveyor, which can recycle large pieces of metal;

[0013] Then, these fully crushed fine slags are sent into the saw-tooth wave jig, which can fully settle the heavy metal particles in the fine slag, and discharge them to the shaker through the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com