Method of shaping machine for shaping key groove of large disc workpiece body

A planer and workpiece technology, which is applied in the field of keyway processing of large disk workpieces, can solve the problems of high cost of enterprises and difficult delivery of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

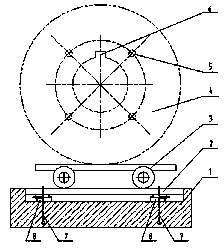

[0012] as attached figure 1 As shown, a method for planing the keyway of a large-scale disc workpiece body on a planer, including a concrete 1 for installing and adjusting pad iron 8 and embedded anchor bolts 7, a trolley 3 that can move horizontally on a flat plate 2, The large disk-like workpiece body 4 of the hydraulic generator is fastened on the planer workbench by "T" bolts through the process hole 5 thereon.

[0013] During work, according to the diameter size of large disk type workpiece body 4, adjust the height of flat plate 2 and the level of flat plate 2 by adjusting pad iron 8, the keyway 6 to be processed on the large disk type workpiece body 4 is to be installed on the planer slide It is realized by the reciprocating linear motion of the knife rod on the pillow. The feed in the horizontal direction depends on the workbench guide rail of the planer, through the process hole 5 of the large workpiece body, use "T" bolts to fasten the large workpiece body on the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com