Manufacturing method of precision positioning mandrel

A precision positioning, processing and manufacturing technology, applied in the direction of metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as uneven pressure transmission, slipping, and loose clamping of workpieces, so as to shorten auxiliary time, reduce manufacturing costs, reduce The effect of clamping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

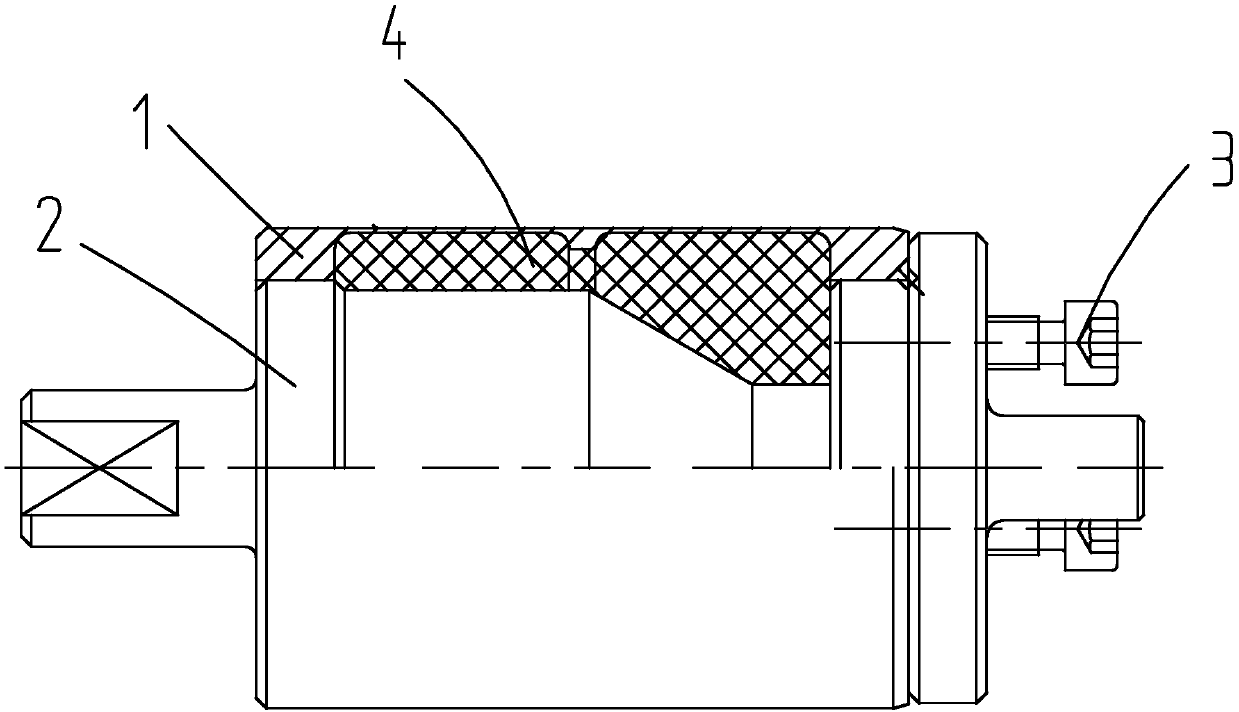

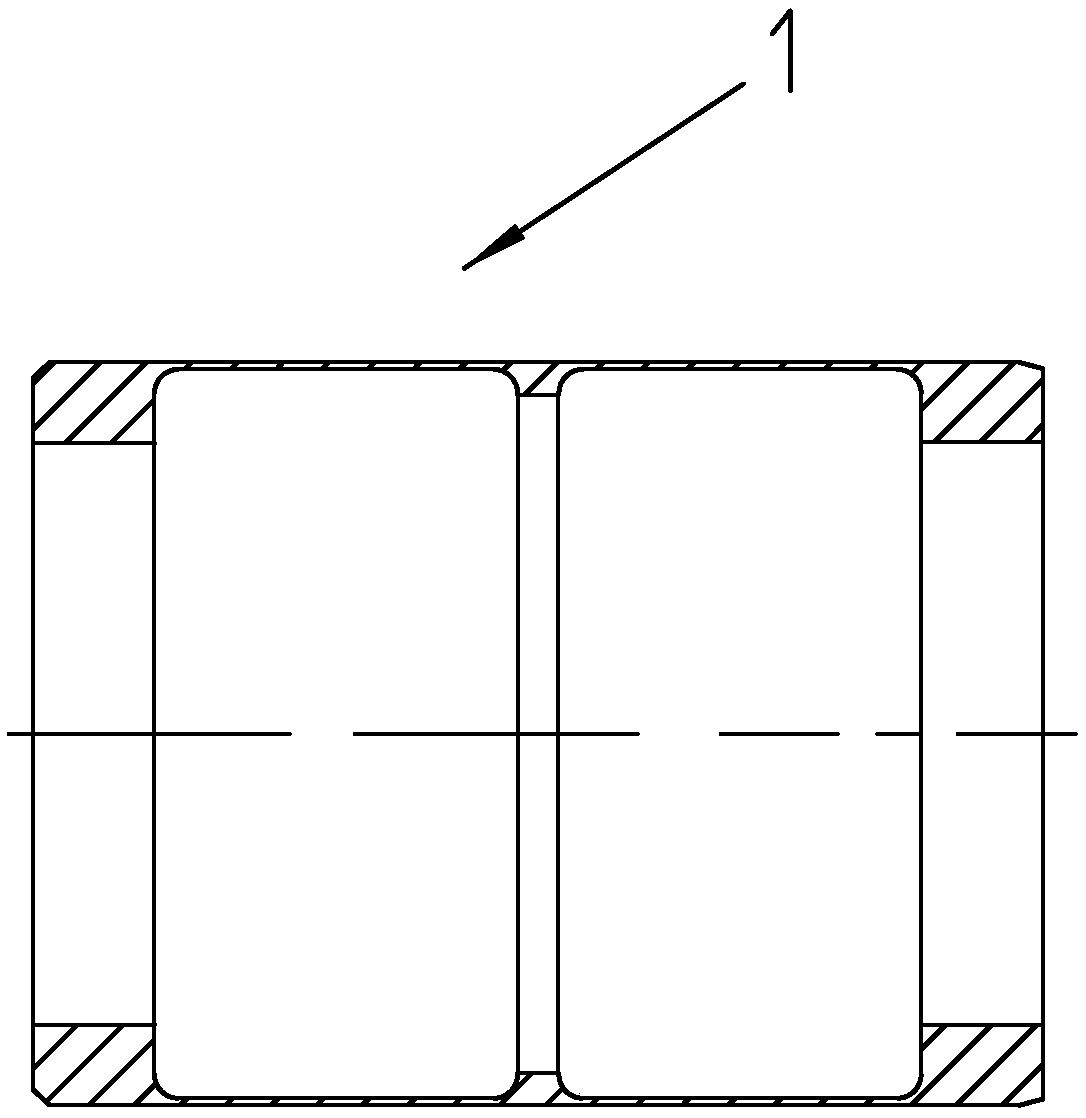

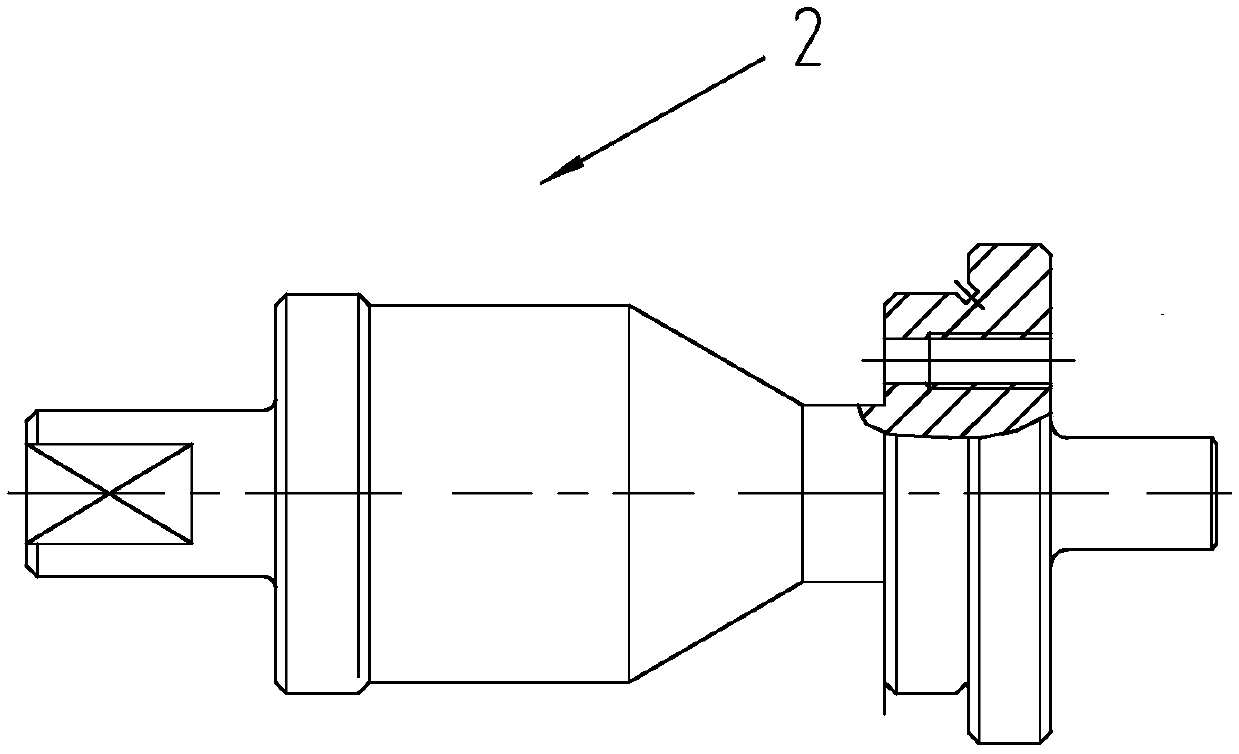

[0065] Such as Figure 1-Figure 4 Shown is the structure of the precision positioning mandrel processed and manufactured by the method of the present invention, wherein 1 is an elastic sleeve, 2 is a mandrel body, 3 is a pressurized hexagon socket head cap screw, and 4 is a liquid synthetic material.

[0066] 1. The structural design process of the precision positioning mandrel is as follows:

[0067] (1) Preparation of workpiece (wheel) positioning reference hole: diameter of inner hole of workpiece (wheel) The precision is H7 grade, and the inner hole length of the workpiece (wheel) is Lg=81mm.

[0068] (2) The design process of the elastic sleeve:

[0069] 1. Design of the maximum diameter expansion ΔDmax of the elastic sleeve:

[0070] If the workpiece is to be centered and clamped on the elastic sleeve, it must be ensured that:

[0071] ΔD=Δmax+Δgy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com