Fibreboard slab pavement process

A process method and technology for slab slabs, which are applied in the field of MDF slab laying process, can solve problems such as slab breakage and slab surface cracks, and achieve the effects of reducing drop, reducing the proportion of cracked slabs, and eliminating cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

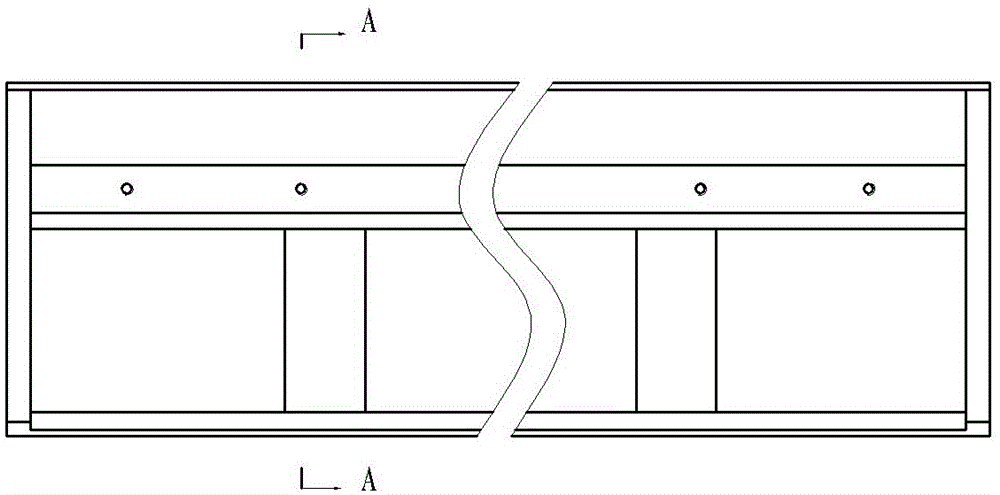

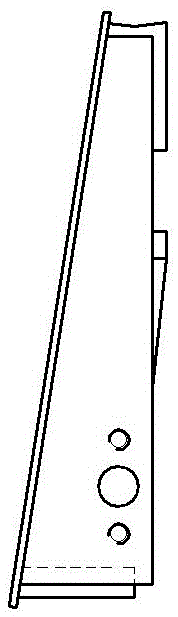

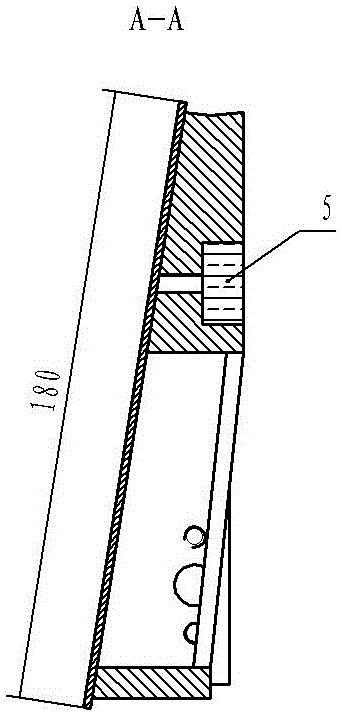

[0022] The raw fiber board slab paving process adopts figure 1 , figure 2 with image 3 The structure diagram of the push pedal head; the length of the push pedal head is 180 mm, the material is 45 steel, the push pedal head hanging lug is welded with the push pedal head panel, and a copper strip 5 is installed at the bottom of the push pedal head to prevent the push pedal head panel from Direct friction with the pressing plate; the slab is unloaded from the loading trolley to the pressing plate due to the high drop, and will be bent. When the strength of the slab is not enough, it is easy to break. 80% of the crack defects are generated on the loading trolley on the other hand, the belt conveyor used in the raw fiber board slab paving process is unstable, and the belt speed fluctuates within a certain range, with the largest fluctuation being 1.5m / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com