Recycling method and device for regenerated waste nitrogen in nitrogen purification process

A technology of nitrogen pollution gas and purification process, applied in the direction of nitrogen purification/separation, chemical industry, climate sustainability, etc., can solve problems such as waste of energy, achieve low cost, save production cost, and save the effect of regeneration gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

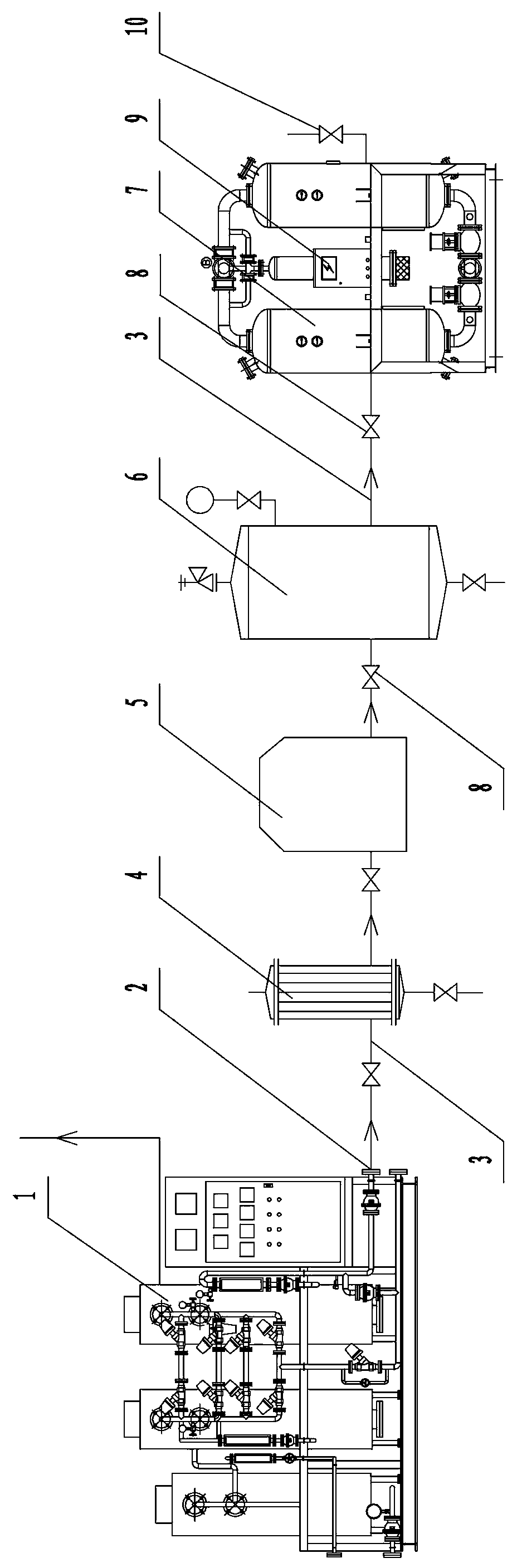

[0016] The recycling method of regenerated polluted nitrogen gas in the nitrogen purification process of the present invention comprises the following steps:

[0017] (1) A water cooler 4 is connected to the pipeline 3 of the regenerated contaminated nitrogen gas outlet 2 of the nitrogen purification device 1. After the water cooler 4, a refrigerated dryer 5, a nitrogen buffer tank 6 and an air micrometer are sequentially arranged through the pipeline. Heat regeneration dryer 7, wherein the gas outlet pipeline of nitrogen buffer tank 6 is connected with the regeneration gas inlet pipeline of air microheat regeneration dryer 7, and valves 8 are installed on each of the above pipelines;

[0018] (2) Open the valve 8 on the outlet pipeline of the regenerated contaminated nitrogen gas, so that the regenerated contaminated nitrogen gas with a temperature of 50-60°C, a pressure of 0.11-0.15MPa, and a normal pressure dew point of 10°C enters the water cooler 4 for cooling, and the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com