Device and method for testing thermal balance of gas cooker

A technology of gas cooker and testing device, which is applied in the direction of measuring device, calorimeter, measuring heat, etc., can solve the problems of not giving smoke exhaust loss, radiant heat loss and heat conduction loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

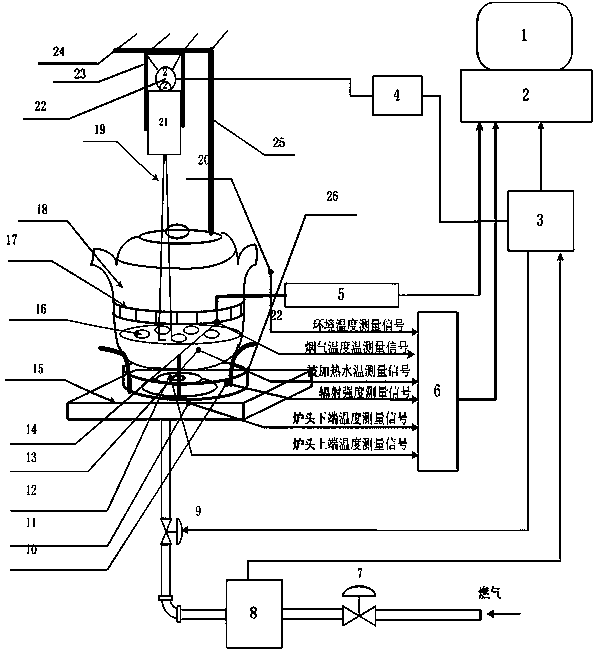

[0072] see figure 1 , the gas cooker heat balance test device, including display (1), computer (2), PLC controller (3), flue gas analyzer (5), multi-channel signal converter (6), gas wet flow meter (8) , solenoid valve (9), radiation intensity sensor (10), temperature sensor at the lower end of the burner (11), temperature sensor at the upper end of the burner (12), water temperature sensor (13), flue gas temperature sensor (14), and the tested cooker ( 15), smoke collector (17), water kettle (18), ambient temperature sensor (20) and radiation intensity sensor bracket (26). It is characterized in that: the ambient temperature sensor (20) is installed in the environment where the kettle (18) is located, the flue gas temperature sensor (14) is installed on the flue gas collector (17), and the flue gas collector (17) is installed on the kettle (18) At the lower flue gas circulation place, the water temperature sensor (13) is fixed on the lid of the kettle (18) and its probe is i...

Embodiment 2

[0074] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0075] The water temperature sensor (13) adopts thermal resistance Pt100; the radiation intensity sensor (10) adopts RHFS30; the temperature sensor at the upper end of the burner (12) and the temperature sensor at the lower end of the burner (11) adopt Pt100; the ambient temperature sensor (20) adopt Pt100; the flue gas temperature sensor (41) adopts Pt100; the multi-channel signal converter (6) adopts SQ2040; the PLC controller (3) adopts Xinjie XC3 series PLC; the flue gas Analyzer (5) adopts Siemens testo350 enhanced flue gas analyzer.

Embodiment 3

[0077] see figure 1, the heat balance test device for gas cookers consists of a display (1), a host computer (2), a PLC controller (3), a stepper motor controller (4), a flue gas analyzer (5), and a multi-channel signal converter ( 6), manual valve (7), gas wet flow meter (8), solenoid valve (9), radiation intensity sensor (10), temperature sensor at the lower end of the burner (11), temperature sensor at the upper end of the burner (12), water temperature sensor (13), flue gas temperature sensor (14), tested stove (15), agitator chassis (16), flue gas collector (17), water kettle (18), agitator stick (19), environment Temperature sensor (20), screw rod (21), stepper motor (22), screw rod fixing bracket (23), upper plane (24), upper plane fixing bracket (25) and radiation intensity sensor bracket (26), complete The gas energy consumed by the stove is converted into an estimate of effective absorption energy, flue gas loss energy, radiation loss energy and heat conduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com