Lens focal length measuring device and method based on Fizeau interferomenter

A technology of Fizeau interferometer and lens focal length, which is applied in the field of optical measurement and can solve the problems of low precision, inconvenient operation, and inability to perform measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

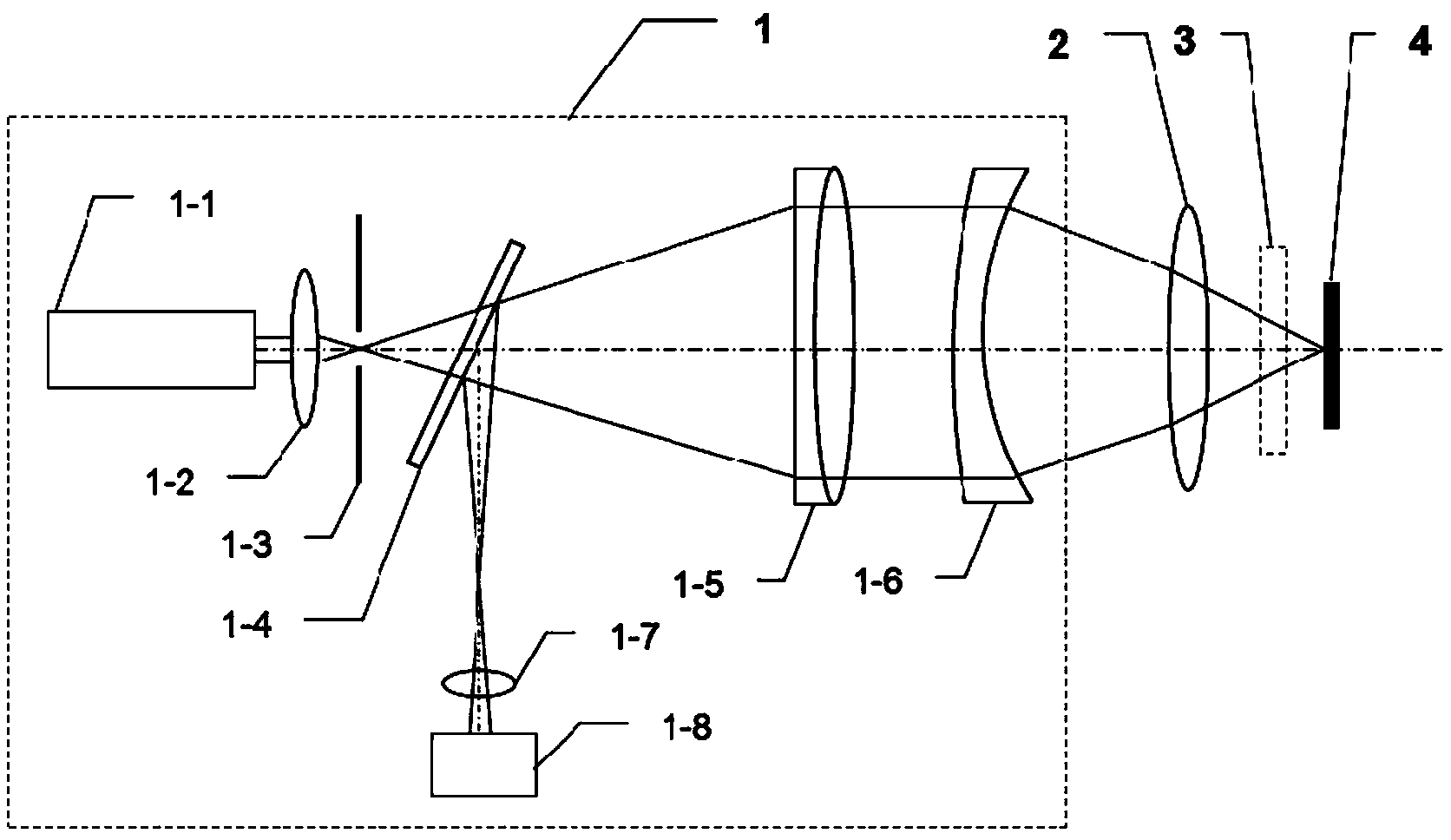

[0093] In the embodiment, the focal lengths of two positive lenses and one negative lens are sequentially detected by using the method of the present invention, and the initial values of the focal lengths of these three lenses are f=536.3mm, 377.9mm, -254.6mm. The working wavelength of the polarization-stabilized He-Ne laser 1-1 is λ=632.8nm, the light beam is converged by the microscope objective lens 1-2, and the focal point is projected onto the spatial filter 1-3, and then collimated by the collimating objective lens 1-5, A beam of parallel light is obtained and enters the interference optical path.

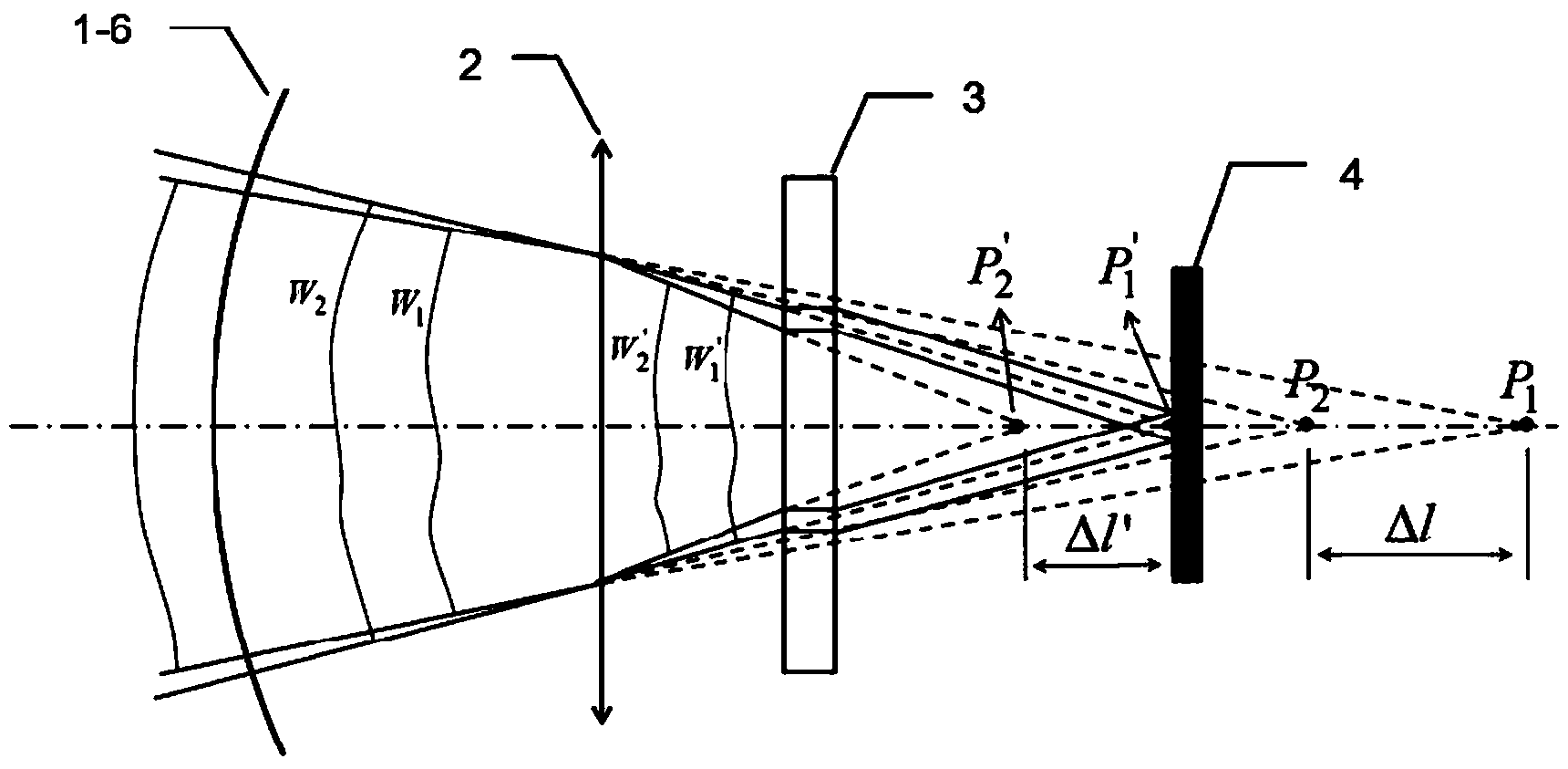

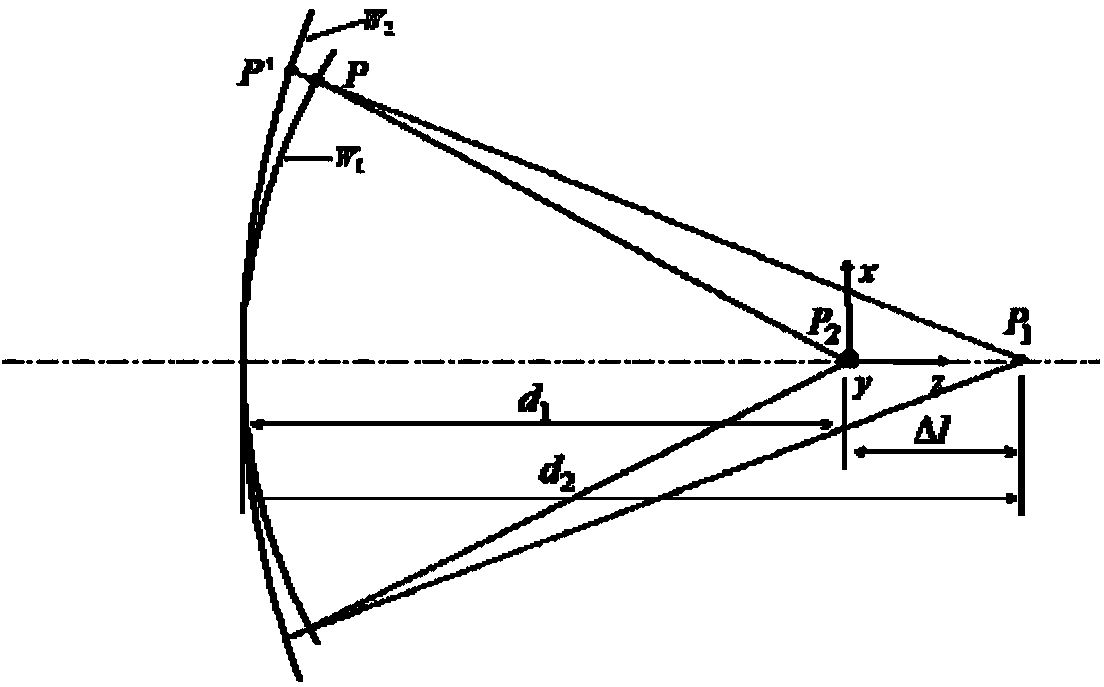

[0094] The steps of using the Fizeau interferometer to detect the focal length of two positive lenses and a negative lens are as follows: Figure 4 As shown, the specific detection steps are:

[0095] 1) Measure the thicknesses of two parallel plates using a white light interferometer (Wyko NT9100) with a resolution of 0.1 μm. The material of the two parallel plates is nBk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com