Plug-in piece type adjustable laser attenuation device

A laser attenuation and insert type technology, which is applied in the direction of optics, optical components, instruments, etc., can solve the problems of easy damage, and achieve the effect of good uniformity, small deformation, and high adjustment accuracy of attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

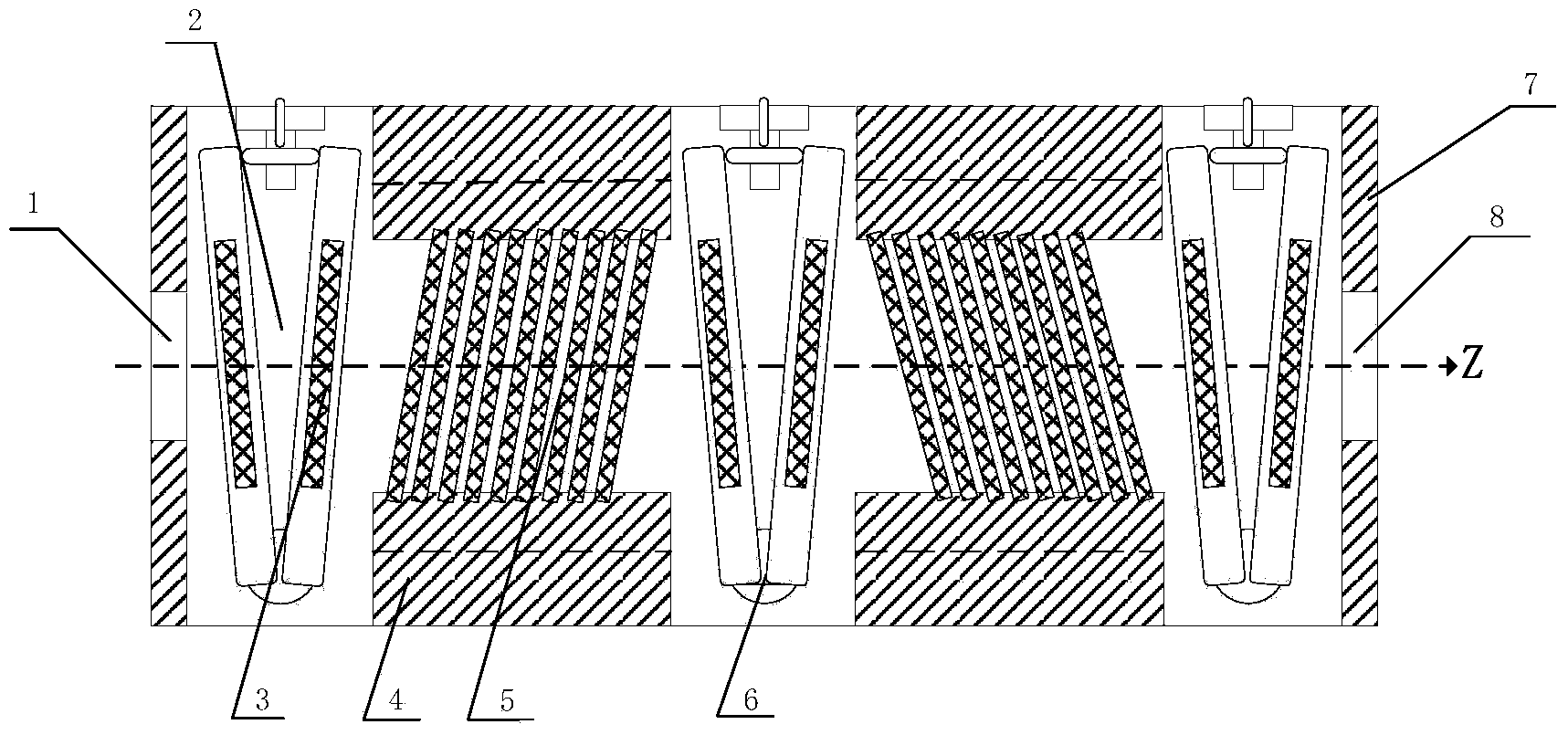

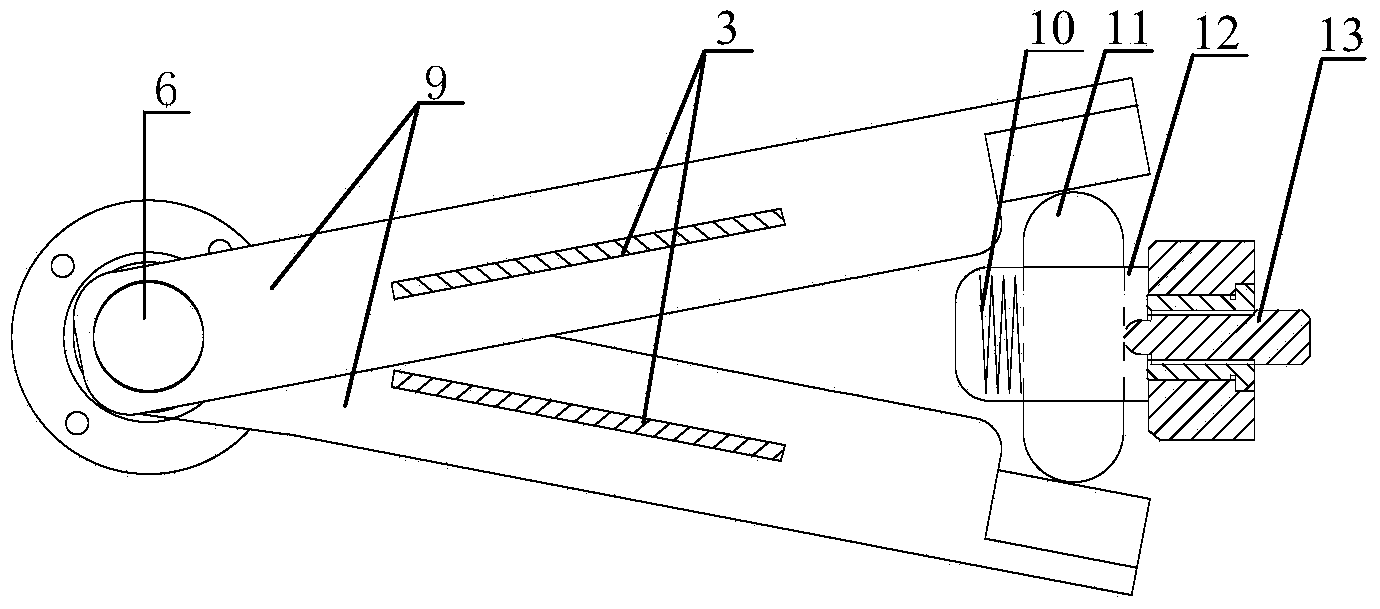

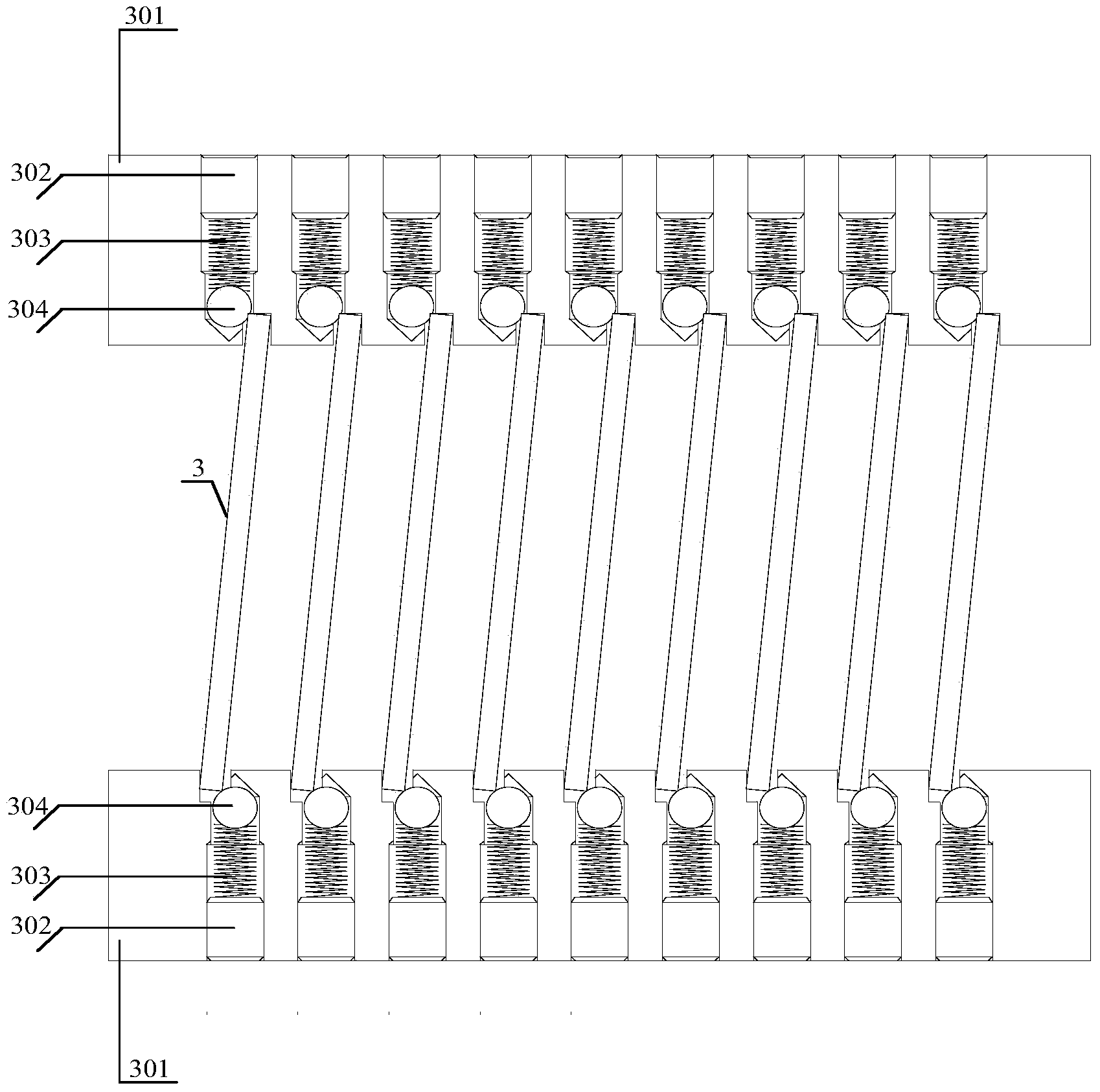

[0027] Embodiment 1: Turn on the laser, the laser beam passes through the incident light-passing hole 1, and a power meter 9 is placed near the exit light-passing hole 8 to observe the attenuated laser beam energy in real time. According to the desired attenuation value, firstly increase or decrease the attenuation lens 3 to realize the rough adjustment of the beam pass rate, and then adjust the fine screw pair 13 to change any fine adjustment attenuation frame pair of the two lens holders with the attenuation lens inserted 9 The angle formed with the straight line passing through the axis of rotation and perpendicular to the Z axis may be 4.5°. The laser beam is repeatedly attenuated by the attenuating lens 3 to obtain a predetermined attenuation value and then output through the exit light hole 8.

Embodiment 2

[0028] Embodiment 2: Turn on the laser, the laser beam passes through the incident light-passing hole 1, and a power meter 9 is placed near the exit light-passing hole 8 to observe the attenuated laser beam energy in real time. According to the desired attenuation value, firstly increase or decrease the attenuation lens 3 to realize the rough adjustment of the beam pass rate, and then adjust the fine screw pair 13 to change any fine adjustment attenuation frame pair of the two lens holders with the attenuation lens inserted 9 The angle formed by the straight line passing through the axis of rotation and perpendicular to the Z axis may be 6.5°. The laser beam is repeatedly attenuated by the attenuating lens 3 to obtain a predetermined attenuation value and then output through the exit light hole 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com