Method and device for color printing solar cell module packaging structure

A solar cell and module encapsulation technology, which is applied in the field of encapsulation and manufacturing, can solve the problems of high technical difficulty of solar panels, heavy weight of solar panels, and non-environmental protection, and achieve lightweight and energy consumption reduction, uniform surface of the encapsulation layer, and reduction of electric energy The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

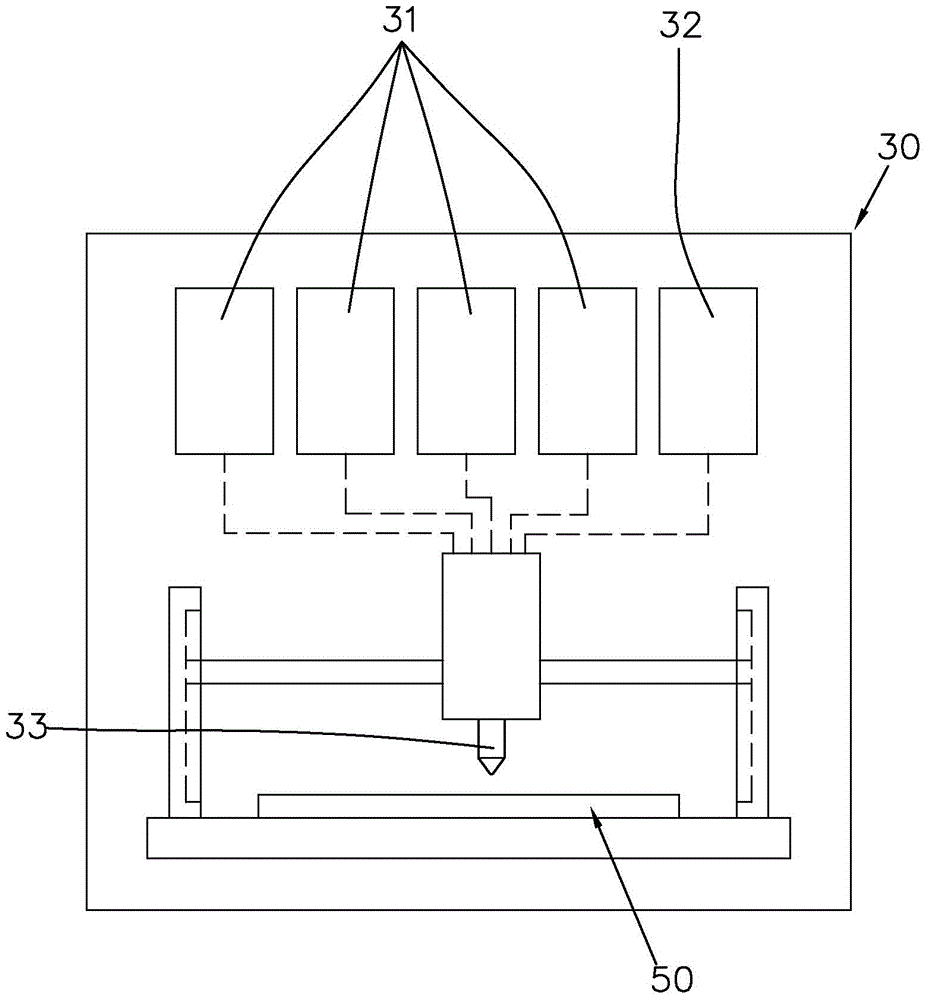

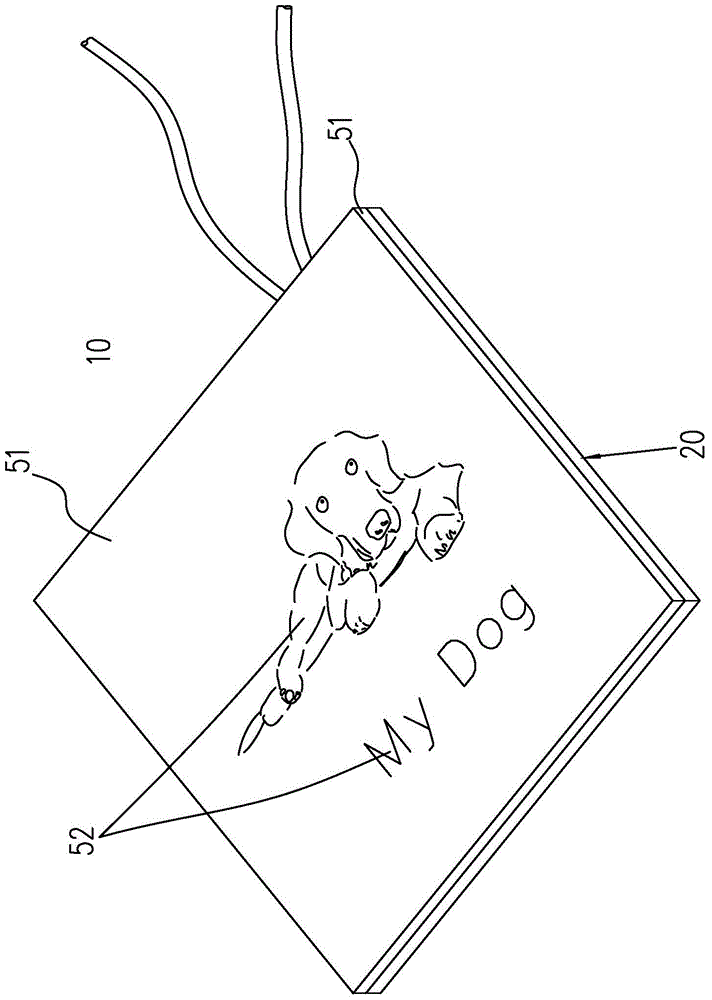

[0061] First please refer to Figure 1 to Figure 2 A device for color printing a solar cell module packaging structure provided by the present invention mainly packages a solar chip 10 on a substrate 20 at room temperature, and includes:

[0062] At least one sealing material has a cured material of ultraviolet adhesive UV component, and each has a predetermined color, and one of the sealing materials is transparent and colorless.

[0063] A printer 30 has a plurality of color ink cartridges 31, each of which is filled with various colors of the sealing material; one of the transparent ink cartridges 32 is filled with transparent and colorless described sealing material, and the printer 30 can have preset The sealing materials of each color are respectively extruded from each of the ink cartridges 31 through the nozzle 33 to form an encapsulation layer 51 with a preset image and text 52 in one printing operation, and the encapsulation layer 51 converts the solar energy The ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com