Optimal control system for chemimechanical pulp technology

A chemical-mechanical and optimized control technology, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., it can solve the problem that multiple single-loop controllers cannot solve the mutual interference of multi-variables, so as to reduce environmental protection effects and enhance operation. , the effect of reducing variance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

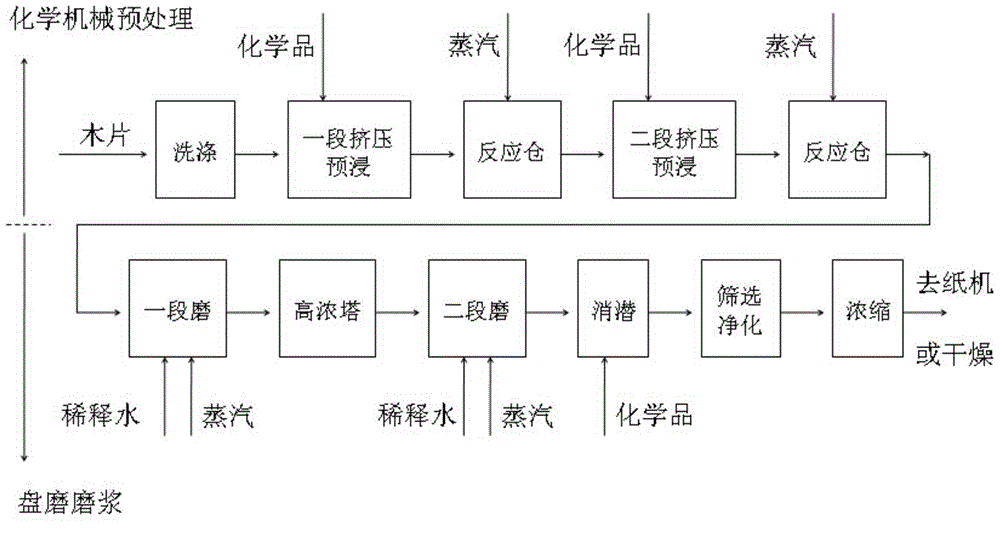

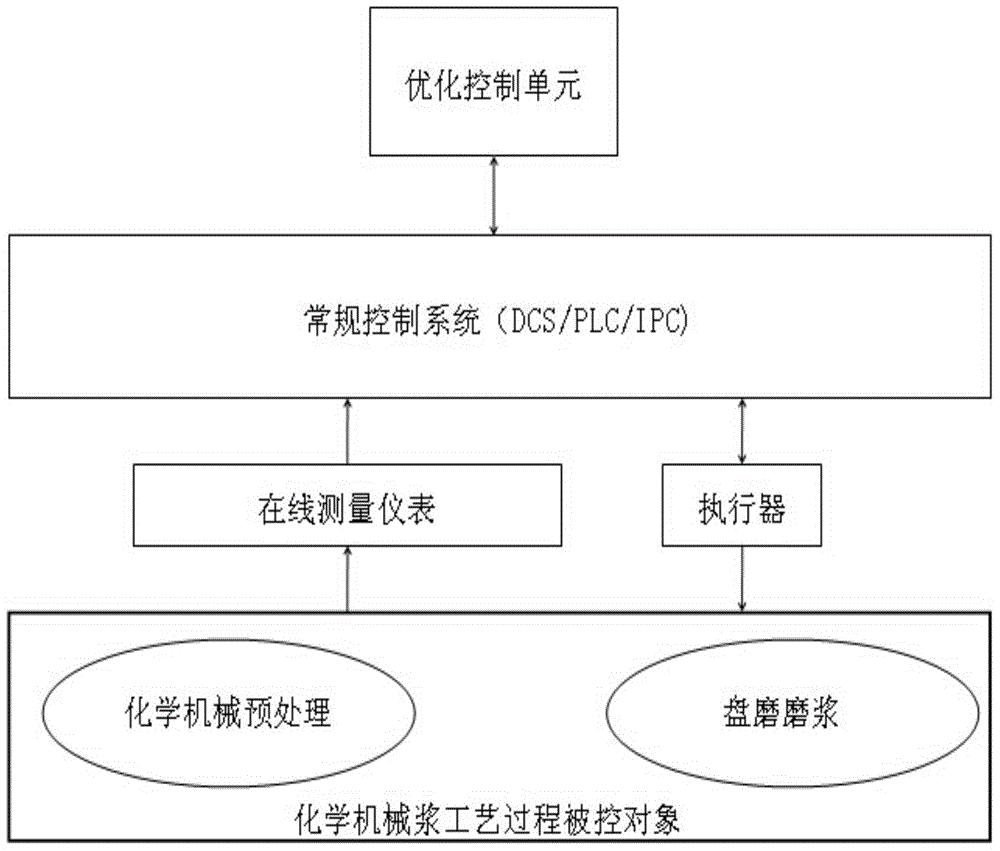

[0034] figure 1 The process shown is a typical chemical mechanical pulp process, and the chemical mechanical pulp process optimization control system of the present invention is integrated with this process as the controlled object, such as image 3 and Figure 6 .

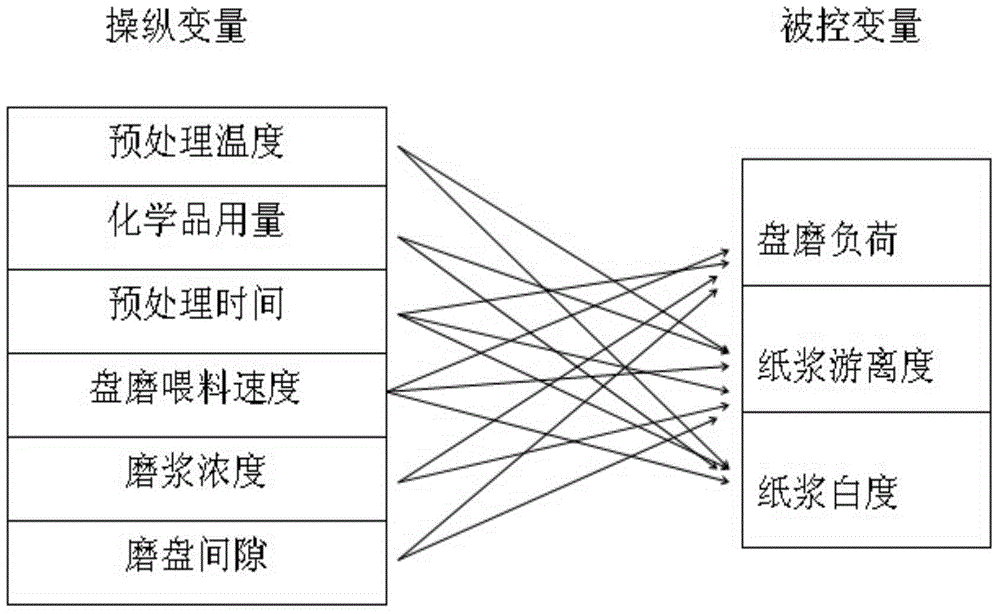

[0035] The optimized control system of the chemical mechanical pulping process described in the present invention is suitable for the production process of the chemical mechanical pulp process. The optimized control system includes a conventional control system, several online measuring instruments, online analyzers, several actuators ), the controlled object of the chemical mechanical pulp process and the optimized control unit. Conventional control system includes upper computer, process controller and I / O input and output modules. Among them, the optimization control unit establishes industrial standard real-time communication with the conventional control system to realize the transmission of control signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com