Physical method for improving crispness of coconut flakes

A physical method, the technology of coconut flakes, which is applied in food science, application, food preparation, etc., can solve the problems of coconut flakes not crisp enough, bad taste, etc., and achieve the effect of improving taste and quality, and increasing crispness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: get the fresh coconut meat of cleaning, against the bundle fiber section of coconut meat, slice thickness is about 3mm~6mm, the coconut slice that cut is boiled 30min together with 20% white granulated sugar solution, take out and drain. After drying, put it into the oven and bake at a high temperature of 120°C until the surface of the coconut meat is golden yellow for 90 minutes, then adjust the temperature to 100°C and continue to bake for 10 minutes, take it out and cool to room temperature, The result is coconut flakes that are crispy and tasty.

Embodiment example 2

[0026] Implementation example 2: Take the washed fresh coconut meat, slice against the bundled fibers of the coconut meat, the thickness of the slice is about 3mm to 6mm, boil the cut coconut flakes with 25% white granulated sugar solution for 25min, take out and drain After drying, put it into the oven and bake at a high temperature of 150°C until the surface of the coconut meat turns golden yellow for 35 minutes, then adjust the temperature to 90°C and continue to bake for 10 minutes, then take it out to get crispy and delicious taste Excellent coconut flakes.

Embodiment example 3

[0027] Implementation example 3: Take the washed fresh coconut meat, slice against the bundled fibers of the coconut meat, the thickness of the slice is about 3mm-6mm, boil the cut coconut slices with 30% white sugar solution for 20min, take out and drain After drying, put it into the oven and bake at a high temperature of 200°C until the surface of the coconut meat turns golden yellow for 15 minutes, then adjust the temperature to 80°C and continue to bake for 15 minutes, then take it out to get a crispy texture Excellent coconut flakes.

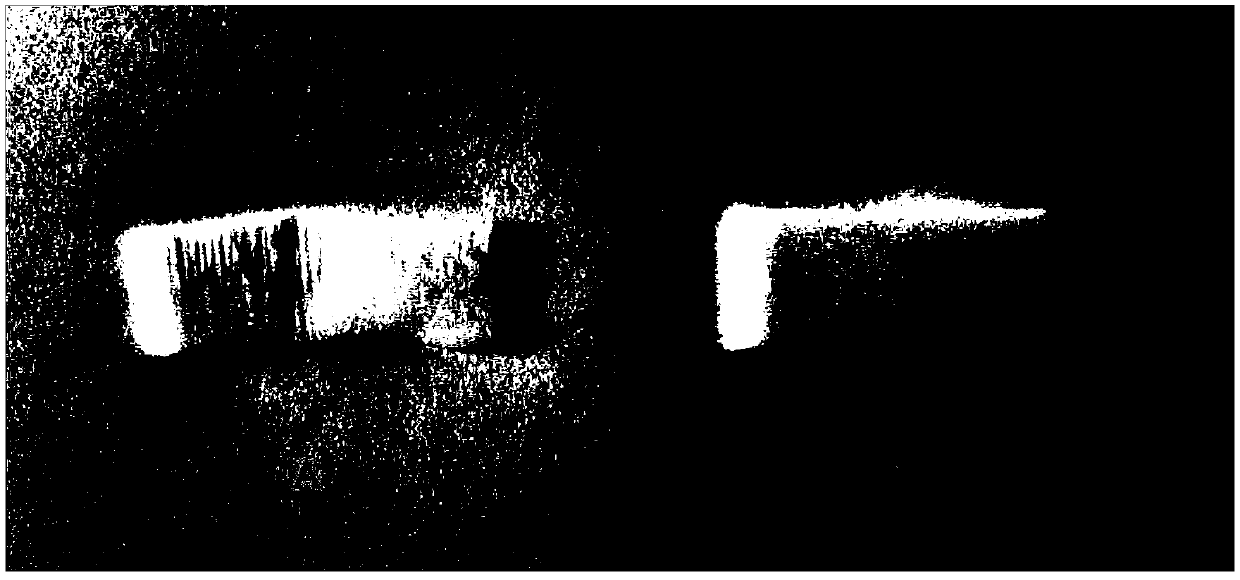

[0028] Such as figure 1 As shown, the coconut meat of different slicing modes is observed, and it is found that the copra bundle-like fibers of traditional slicing modes are obvious, (see figure 1 A), the sensory and crispness of coconut flakes will be affected after toasting. And the copra sliced against the bundle of fibers of the copra (see figure 1 B), the surface is smoother, the bundle fiber structure is destroyed and loosened, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com