Forming technology and forming device for liquid residues

A molding device and molding process technology, which is applied in the field of coal liquefaction, can solve the problem of smoke spreading to the outside world, and achieve the effects of improving heat exchange efficiency, high hardness, and large thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

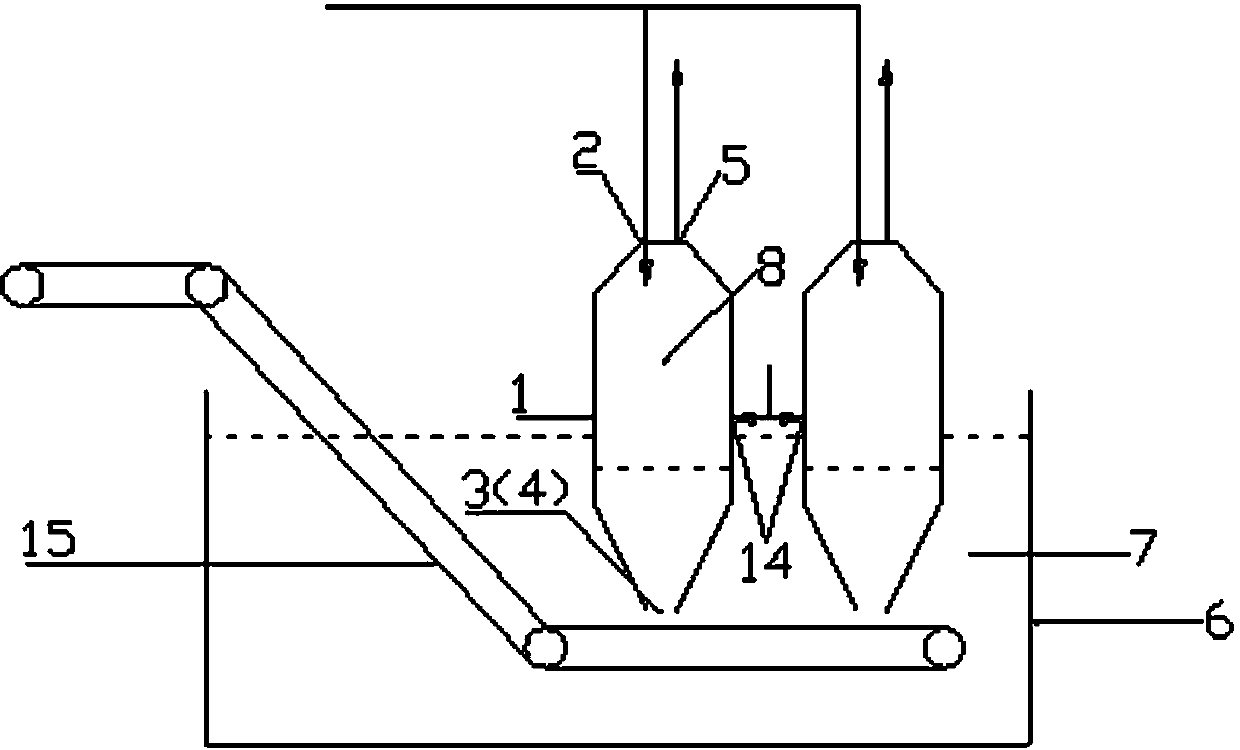

[0042] The forming device of the liquid residue of the present invention, such as figure 1 As shown, it includes a cooling tower 1, the top is provided with a liquid residue inlet 2 (also can be arranged in the upper part), the bottom is provided with a liquid residue outlet 3 (also can be arranged in the lower part), and a first coolant inlet 4 and a gas outlet are also provided. 5. The positions of the first coolant inlet 4 and the gas outlet 5 can be selected. In this embodiment, the first coolant inlet 4 is set at the bottom of the cooling tower 1 (it can also be set at the bottom), so The gas outlet 5 is set on the top of the cooling tower 1 (it can also be set on the upper part); the first coolant inlet 4 can be selected to communicate with or not communicate with the inside of the forming tank 6. In this embodiment, the first A coolant inlet 4 communicates with the cavity 7 in the forming groove 6, the first coolant inlet 4 can be used as the liquid residue outlet 3;

...

Embodiment 2

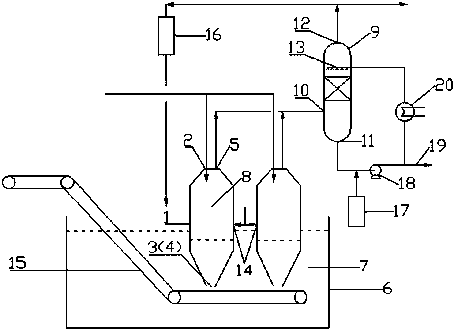

[0046] Based on the above, as a variable implementation method, such as figure 2 As shown, it also includes a washing tower 9, the lower part is provided with an air inlet 10 (also can be arranged at the bottom), the bottom is provided with a liquid outlet 11 (also can be arranged at the lower part), and the top is provided with an air outlet 12 (also can be arranged at the bottom) upper part); in the washing tower 9, a spray head 13 is arranged near the gas outlet 12; the air inlet 10 communicates with the gas outlet 5 of the cooling tower 1. In order to improve the heat exchange effect between the first coolant and the liquid residue, the lower part of the cooling tower 1 is provided with a ventilation hole 14 (it can also be arranged at the bottom), and the introduction of air into the ventilation hole 14 can accelerate the upward flow of the first coolant speed. Also includes an air cooler 16, the air cooler 16 is provided with a gas inlet and a water outlet, the gas inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com