laser processing machine

A laser processing machine, laser technology, applied in the direction of metal processing, laser welding equipment, metal processing equipment, etc., can solve the problems of time-consuming and long time, and achieve the effect of eliminating waste, shortening time, and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

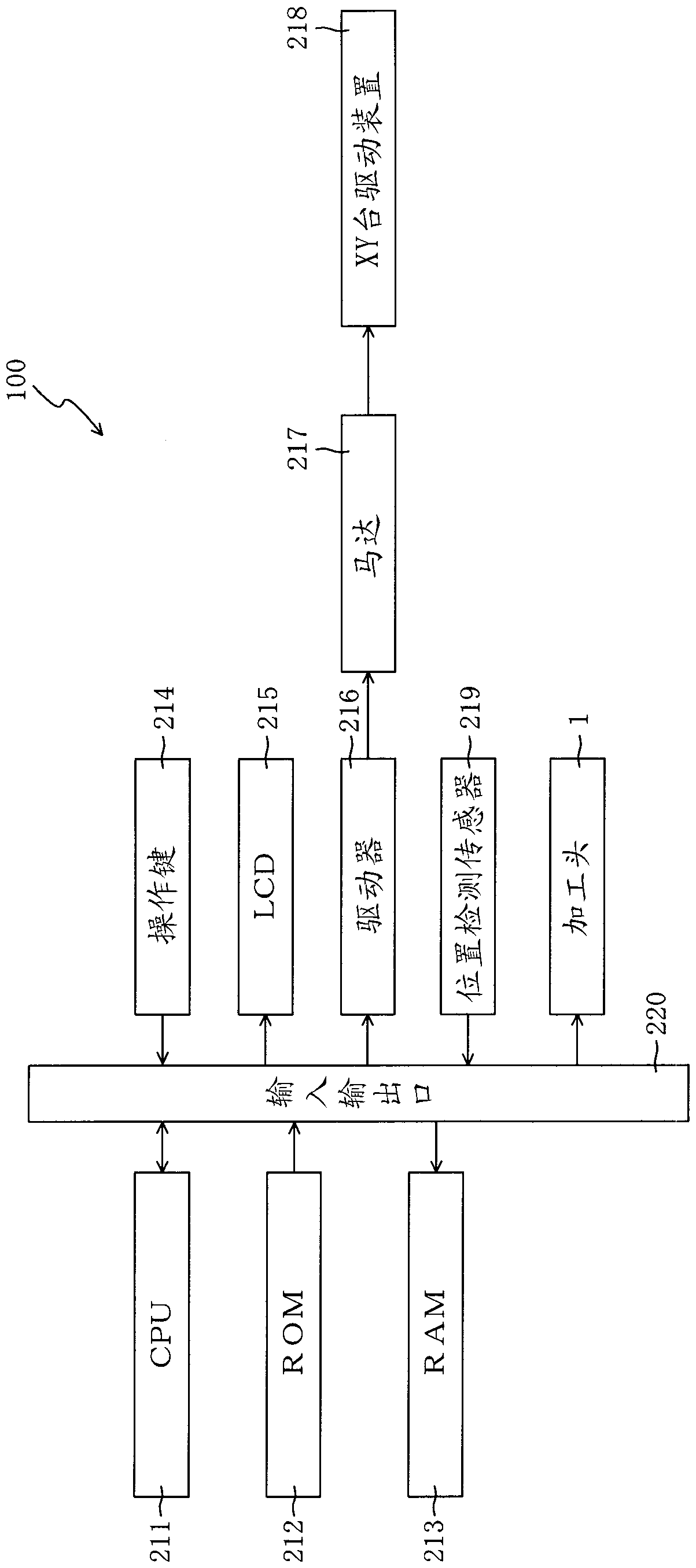

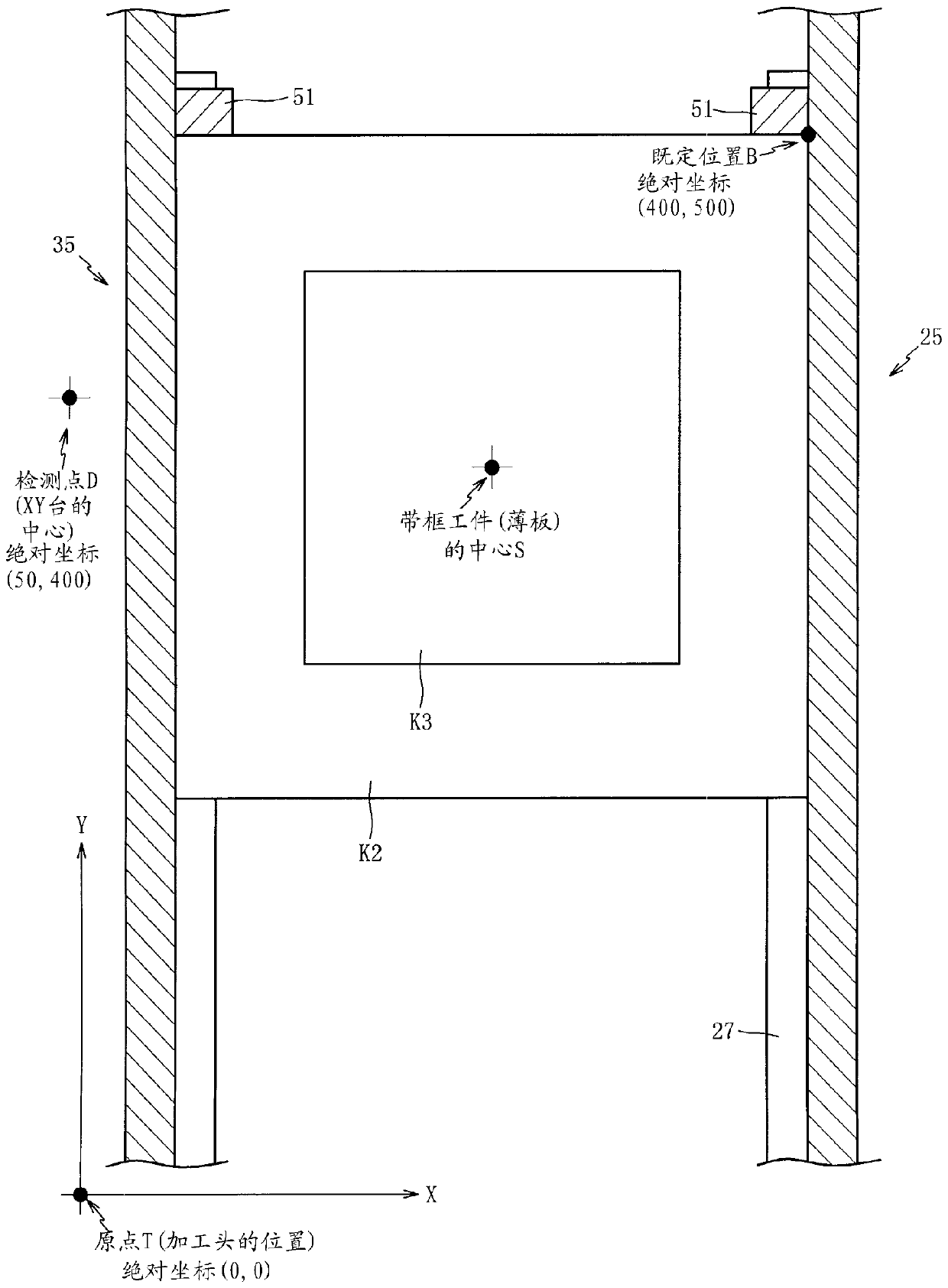

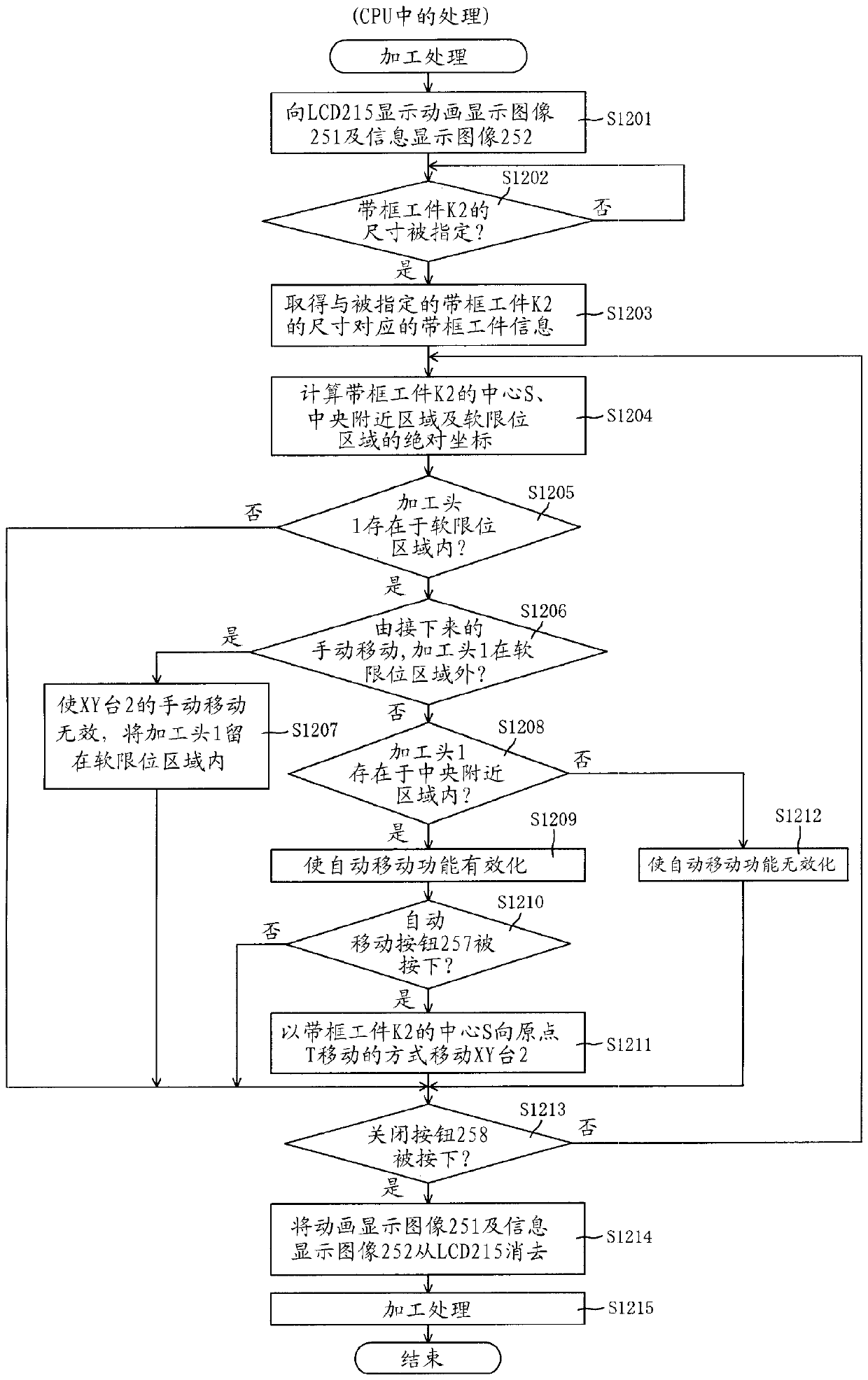

[0033]Next, embodiments of the laser processing machine of the present invention will be described below with reference to the drawings. First, refer to Figure 1 to Figure 4 The laser processing machine 100 of the first embodiment will be described. figure 1 It is a figure which schematically shows the main structure of the laser processing machine 100 of 1st Embodiment. The laser processing machine 100 processes a stainless steel plate that is masked to apply the solder only to necessary portions of the substrate when applying solder to a substrate of an electronic component.

[0034] The stainless steel plate is attached to the mirror-frame-shaped frame to cover and mask the electronic substrate, so the stainless steel plate needs to be attached to the frame. As a method of attaching the stainless steel plate to the frame, there are mainly two methods of attaching the processed stainless steel plate to the frame and attaching the unprocessed stainless steel plate to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com