Efficient energy-saving single-screw extruder

A single-screw extruder and energy-saving technology, which is applied in the field of material processing, can solve the problems of low production efficiency, increased equipment investment, and long residence time of single-screw extruders, so as to avoid overloaded operation of equipment and speed up high efficiency. , the effect of reducing the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

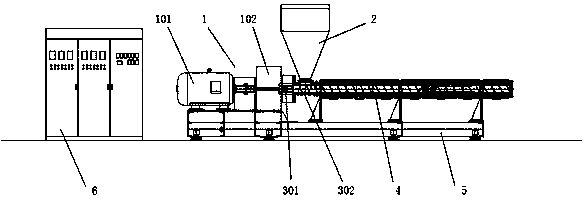

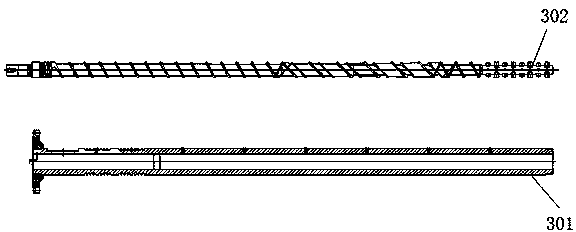

[0019] The high-efficiency and energy-saving single-screw extruder of the present invention includes a conventional device, a hopper 2, a barrel 301, a screw 302, a heating and cooling device 4, a bed 5 and an electrical control device 6.

[0020] The conventional device includes a main motor 101 and a reduction box 102 . The main motor 101 is controlled by the AC frequency converter of the electrical control device 6, and the power of the motor is 30-400KW. The input end of the reduction box 102 is connected with the main motor 101 , and the output end is connected with the screw rod 302 , which can reduce the rotation speed of the motor and increase the torque required for the rotation of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com