Light and high-strength dung leakage plate LFT-D forming process

A technology of LFT-D and forming process, which is applied in animal houses, animal husbandry, applications, etc., can solve the problems of not providing forming process, etc., achieve excellent antimicrobial and antibacterial effects, excellent creep resistance, and stable size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

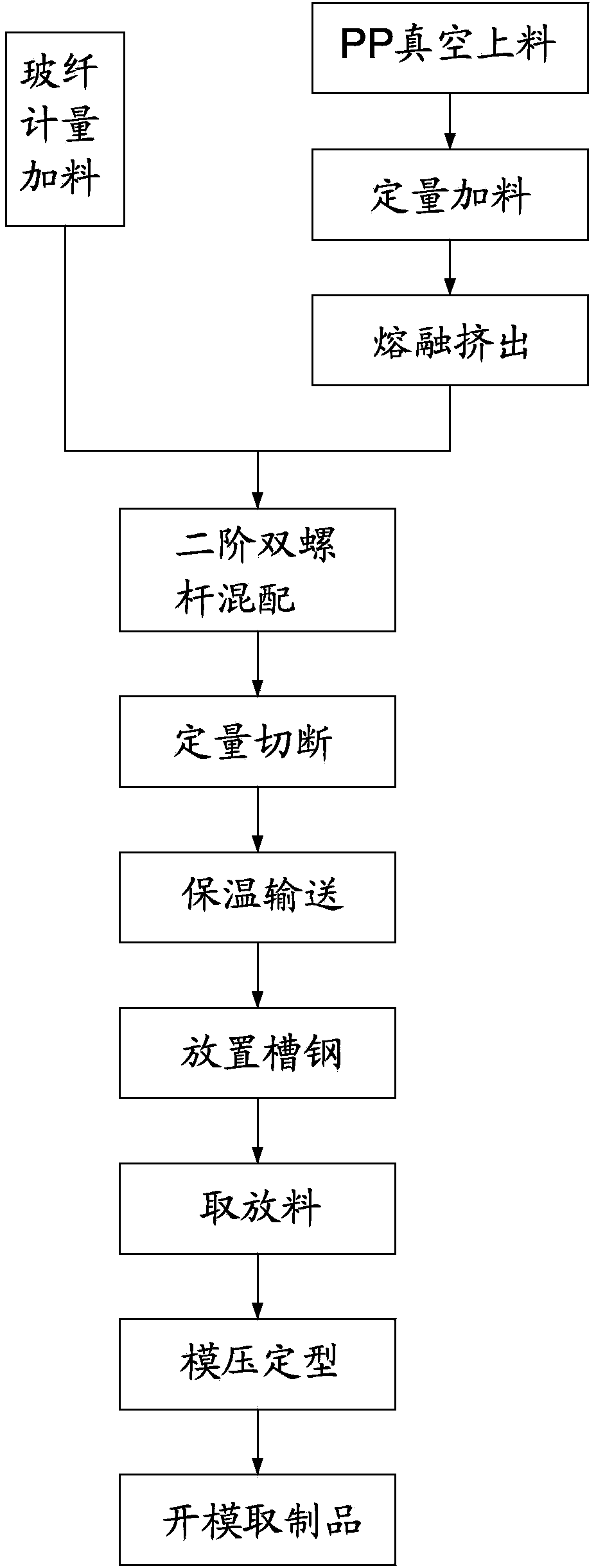

[0032] Such as figure 1 As shown, the lightweight and high-strength leaking dung panel LFT-D molding process of the present invention includes:

[0033] Step 10. Quantify the resin PP from the vacuum feeding system to the vector weighing system according to the weight of the template, and then enter the first-stage twin-screw extruder for heating and melting; the melted PP is sent to the second-stage twin-screw extruder for feeding Wherein, the rotational speed of the first-order screw extruder is set to 130-180rpm / min, and the first-order screw extruder is divided into seven continuous melt plasticizing zones D1~D6 and D machine head, wherein the temperature of D1 is 180 -220°C, the temperature of D2 is 190-230°C, the temperature of D3 is 210-240°C, the temperature of D4~D6 is 215-240°C, and the temperature of D head is 215-240°C;

[0034] At the same time, the glass fiber is sent to the second-stage twin-screw machine through the glass fiber frame, and the glass fiber is me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com