Pressure-maintaining oil tank of aircraft

A fuel tank and aircraft technology, applied in the field of aviation aircraft, can solve the problems of occupying a large space on the aircraft, complex fuel tank structure, and increased aircraft cost, and achieve the effects of protecting the fuel tank, simple structure principle, and light weight of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

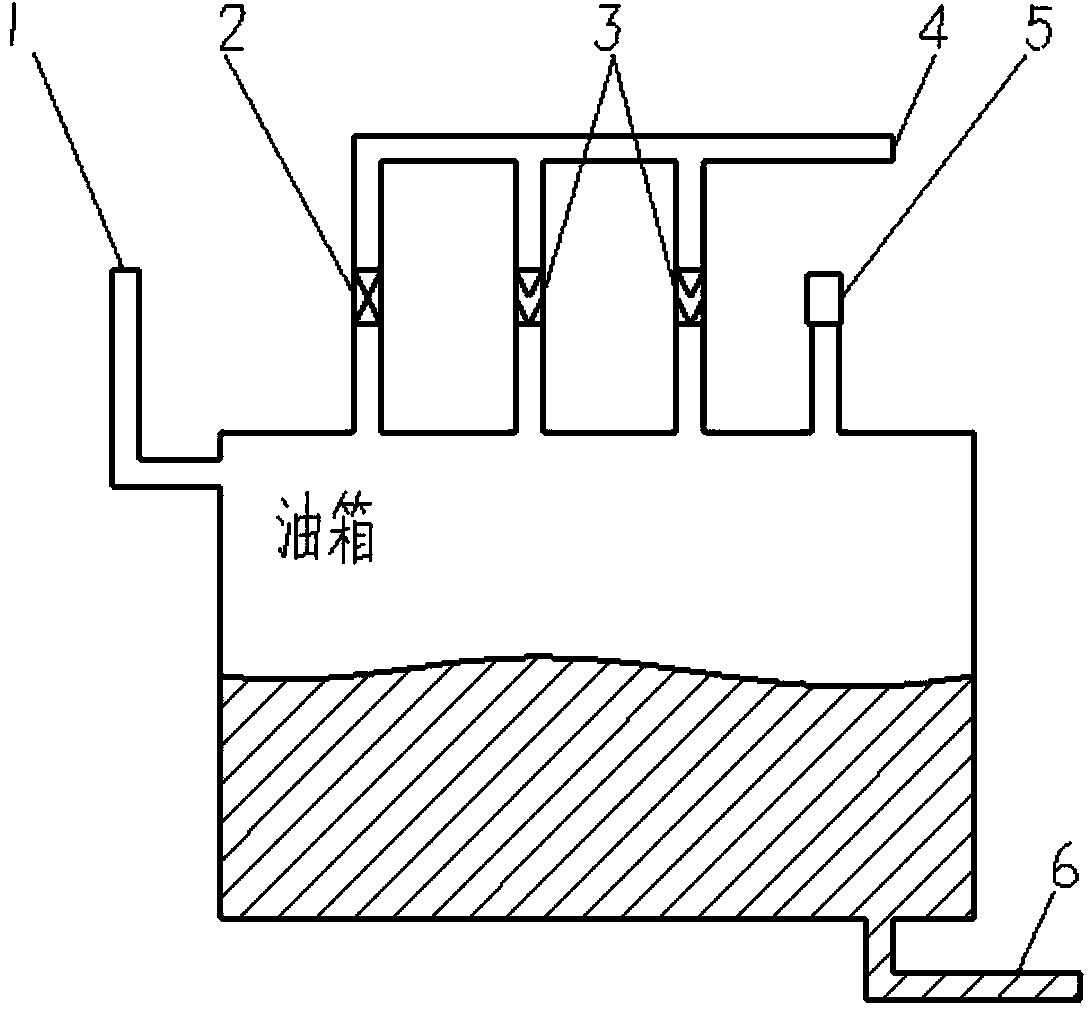

Image

Examples

Embodiment Construction

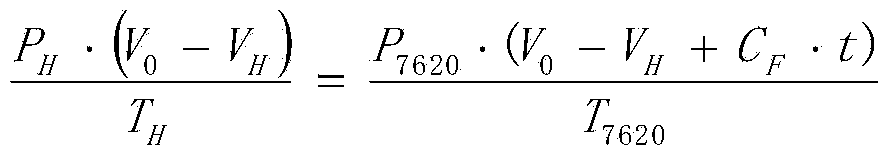

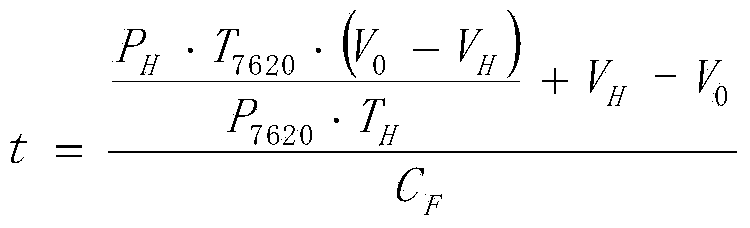

[0024] Suppose an aircraft is equipped with an aviation piston engine with a cruising altitude of 6000-7000m, a fuel tank volume of 900L, and an average fuel consumption rate of 20L / h. It needs to fly at a ceiling altitude of 8000m. The pressure-holding fuel tank of this patent is installed and can be closed at a height of 6500m. Cut off the valve, if the remaining fuel in the fuel tank is 500L at this time, the working time of the fuel tank is 2.7h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com