A roasted potato spice, its preparation method and its application in cigarettes

A technology of baked potatoes and spices, applied in the fields of application, essential oils/spices, tobacco, etc., can solve the problems that have not been reported, and achieve the effects of low cost, improved sensory comfort, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

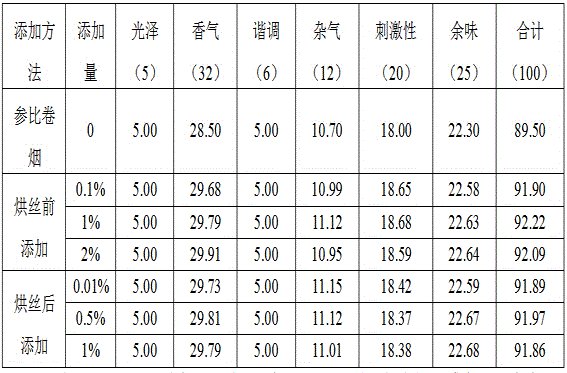

Examples

Embodiment 1

[0022] (1) Washing and peeling, crushing and beating, and decompression filtration: select mature potatoes with a single weight of 100-150g, remove the surface sediment with clean water and drain, wipe off the skin with a wire ball; cut the potatoes with a kitchen knife to a thickness of 5 ~6mm flakes are mixed according to the ratio of water and potato mass ratio of 1:1, using a high-speed tissue masher for beating for 5 minutes, and the rotating speed is 11000rpm to obtain potato pulp; the gained potato pulp is poured on the filter paper of the Buchner funnel, and the press filter to obtain the filtrate;

[0023] (2) Yeast fermentation: add edible active yeast (the content of active dry yeast is 0.2% of the mass of the filtrate) to the filtrate, and incubate at a constant temperature of 35°C for 2 hours to obtain a culture medium;

[0024] (3) Baking at high temperature: put the culture medium in an oven, and bake at 130°C for 3 hours to obtain the aroma substance of roasted...

Embodiment 2

[0030] (1) Washing and peeling, crushing and beating, and decompression filtration: select mature potatoes with a single weight of 120-160g, remove the surface sediment with clean water and drain, wipe off the skin with a wire ball; cut the potatoes with a kitchen knife to a thickness of 5 ~6mm flakes are mixed according to the ratio of water and potato mass ratio of 5:1, and the high-speed tissue masher is used for beating for 10min, and the rotating speed is 12000rpm to obtain potato pulp; the gained potato pulp is poured on the filter paper of the Buchner funnel, press filter to obtain the filtrate;

[0031] (2) Yeast fermentation: add edible active yeast (the content of active dry yeast is 0.1% of the mass of the filtrate) to the filtrate, and incubate at a constant temperature of 40°C for 3 hours to obtain a culture medium;

[0032] (3) Baking at high temperature: put the culture medium in an oven, and bake at 170°C for 1.5 hours at high temperature to obtain the aroma su...

Embodiment 3

[0038] (1) Washing and peeling, crushing and beating, and decompression filtration: select mature potatoes with a single weight of 90-140g, remove the surface sediment with clean water and drain, wipe off the skin with a wire ball; cut the potatoes with a kitchen knife to a thickness of 5 ~6mm flakes are mixed according to the ratio of water and potato mass ratio of 10:1, using a high-speed tissue masher for beating for 20min, and the rotating speed is 10000rpm to obtain potato pulp; the gained potato pulp is poured on the filter paper of the Buchner funnel, and the press filter to obtain the filtrate;

[0039] (2) Yeast fermentation: add edible active yeast (the content of active dry yeast is 0.4% of the mass of the filtrate) to the filtrate, and incubate at 30°C for 1.5 hours to obtain a culture medium;

[0040] (3) Baking at high temperature: put the culture medium in an oven, and bake at 200°C for 1 hour to obtain the aroma substance of roasted potatoes;

[0041] (4) Homo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com