Er-containing Al-based bulk metallic glass alloy with large supercooling liquid phase region

A supercooled liquid phase, metallic glass technology, applied in the field of new materials, to achieve the effects of good mechanical properties, low glass turning temperature, and large glass forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

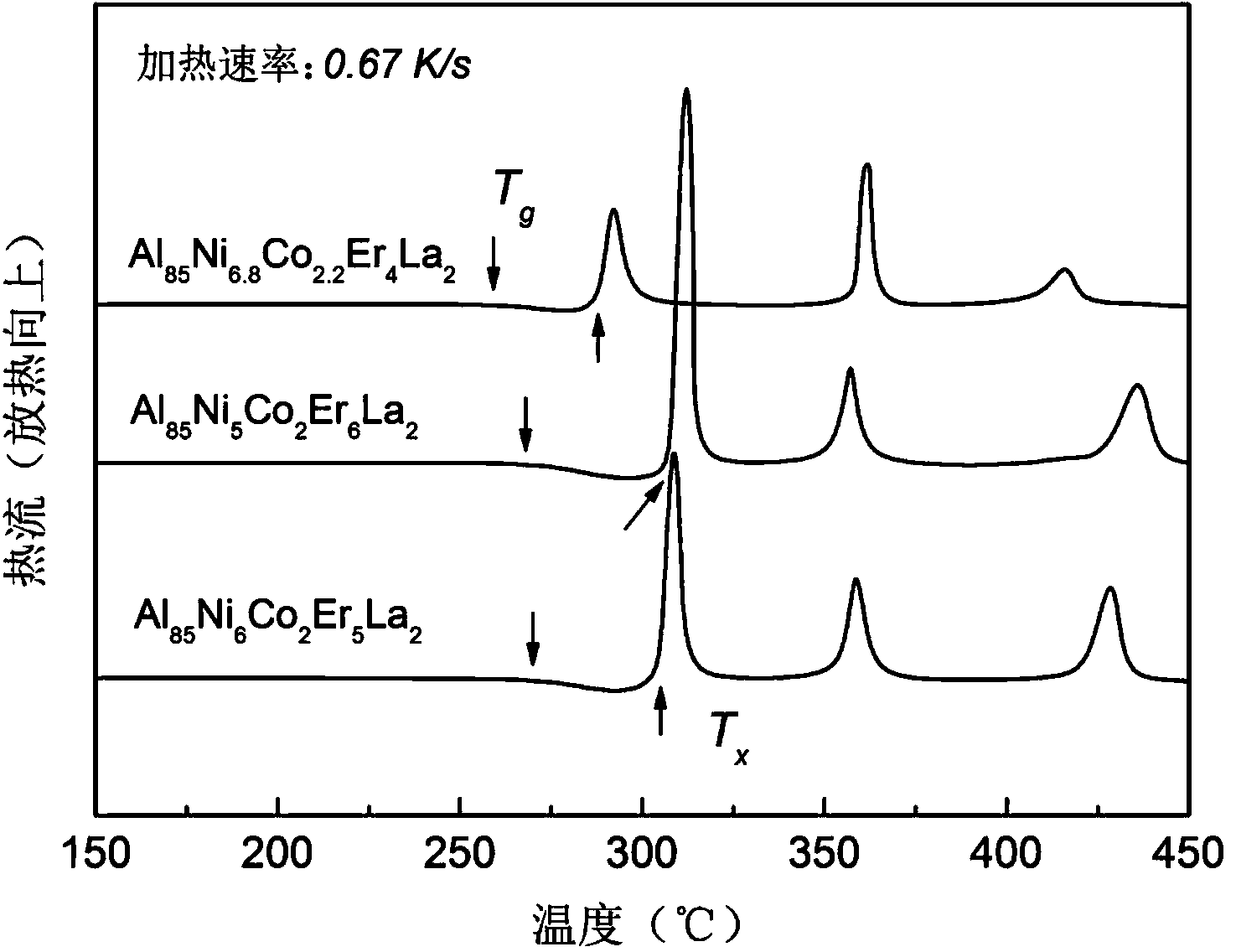

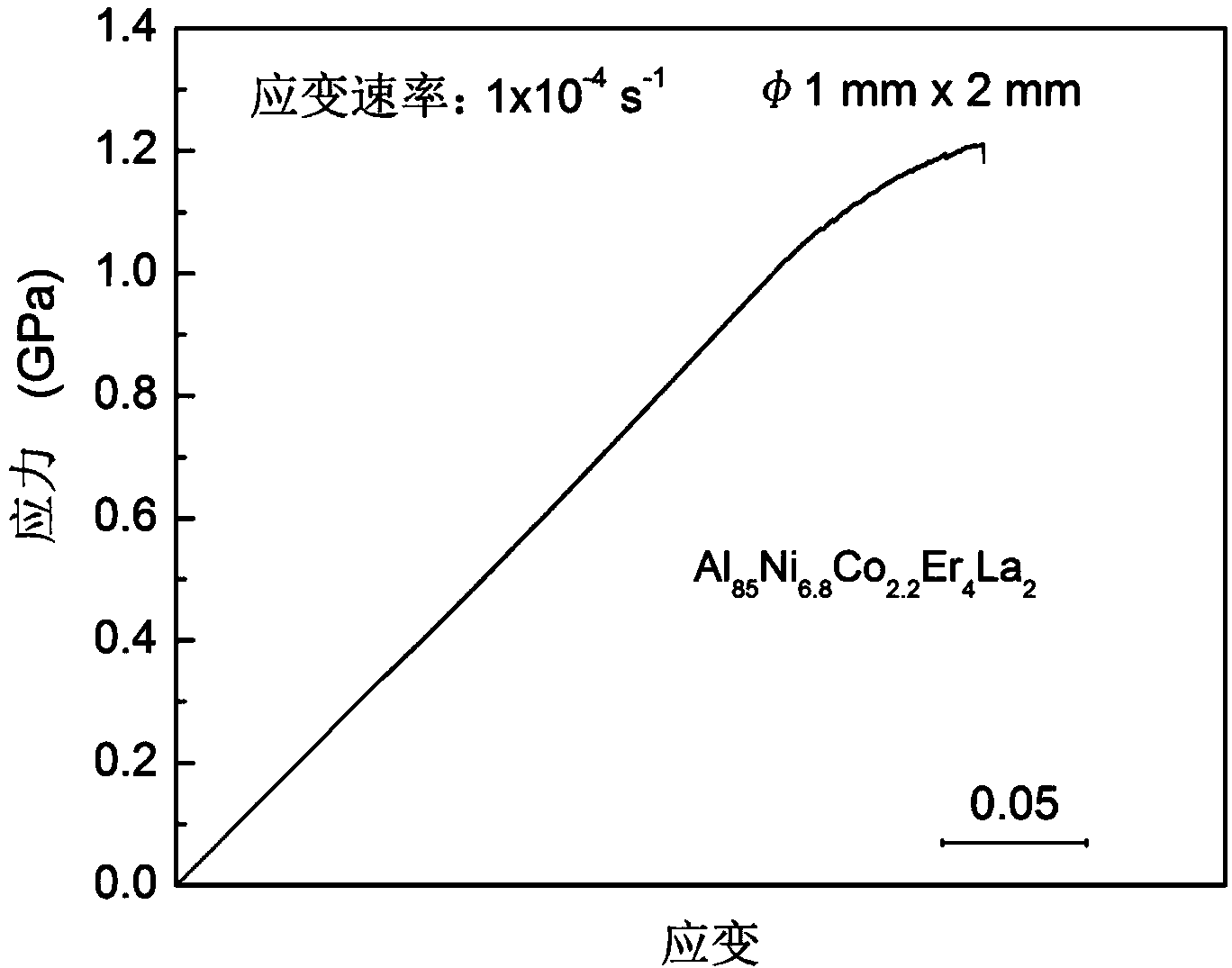

[0018] al 85 Ni 6.8 co 2.2 Er 4 La 2 Preparation, structure and performance testing of bulk metallic glass alloys:

[0019] Step 1: Al, Ni, Co, Er and La raw materials with a purity greater than 95wt.% are used for compounding according to the composition expression.

[0020] Step 2: Preparation of master alloy ingot: Put the raw materials with a good ratio into the copper crucible of the non-consumable electric arc furnace, and evacuate to 2×10 -3 Pa, filled with argon gas, then arc smelted and the alloy was smelted repeatedly 4 times to obtain a master alloy ingot with uniform composition.

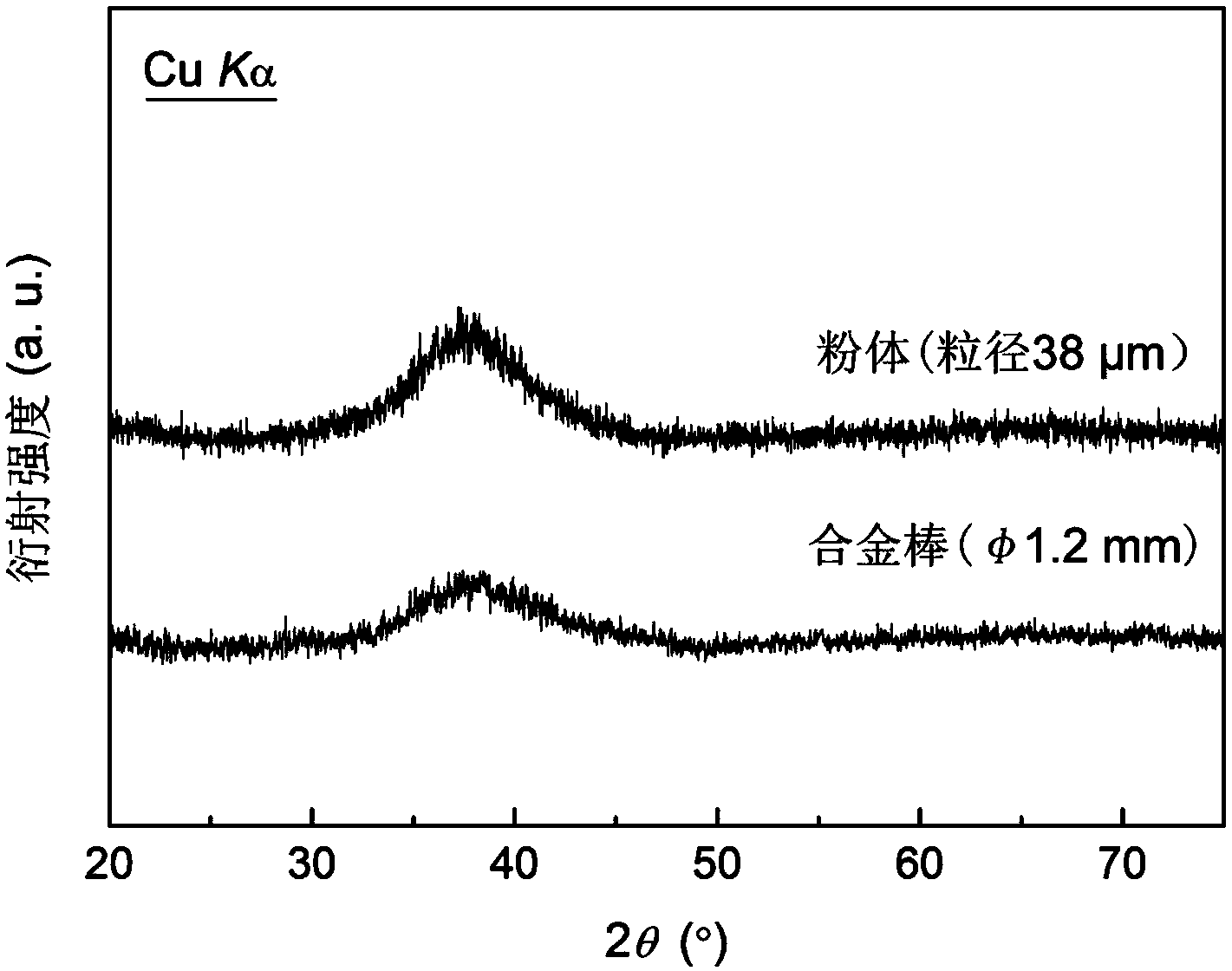

[0021] Step 3: Preparation of metallic glass powder: Put the master alloy ingot into the powder making equipment and vacuumize to 2×10 -3 Pa, fill with argon gas, and heat the master alloy to a molten state by high-frequency induction melting. Turn on the spray switch, let the molten metal liquid pass through the high-pressure argon gas, use the high-pressure gas to spray the allo...

Embodiment 2

[0029] al 85 Ni 6.8 co 2.2 Er 3 La 3 Preparation, structure and performance testing of bulk metallic glass alloys:

[0030] (1) Al, Ni, Co, Er and La raw materials with a purity greater than 95wt.% are used for batching according to the composition expression;

[0031] (2) The implementation steps of master alloy ingot preparation, metallic glass powder and rod preparation, and alloy performance testing are the same as in Example 1, and the detailed data are listed in the attached table.

Embodiment 3

[0033] al 86 Ni 6 co 2 Er 4 La 2 Preparation, structure and performance testing of bulk metallic glass alloys:

[0034] (1) Al, Ni, Co, Er and La raw materials with a purity greater than 95wt.% are used for batching according to the composition expression;

[0035] (2) The implementation steps of master alloy ingot preparation, metallic glass powder and rod preparation, and alloy performance testing are the same as in Example 1, and the detailed data are listed in the attached table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com