Preparation method of environment-friendly type protein leather for earphones

A protein and earphone leather technology, applied in textiles and papermaking, etc., can solve the problems of earphone leather scratching human skin, improve the formula and process, and solve the uncomfortable effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

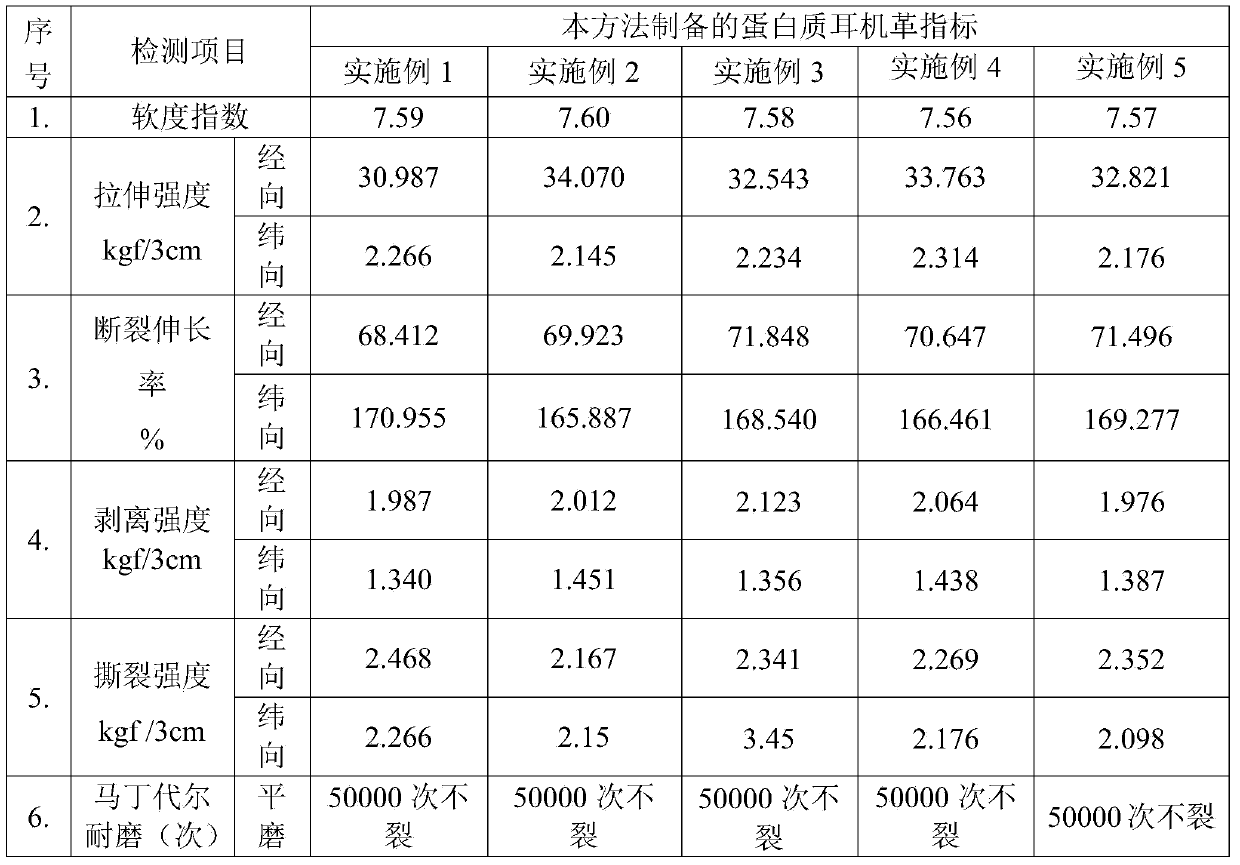

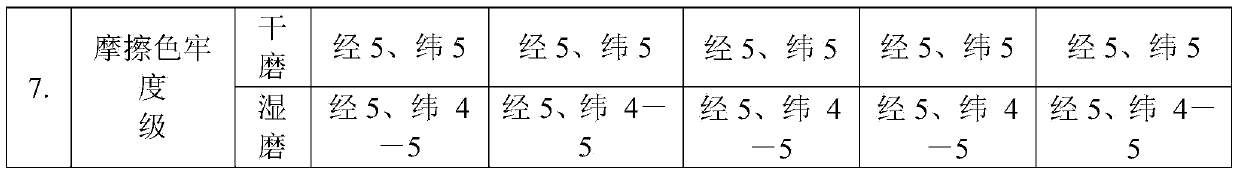

Examples

preparation example Construction

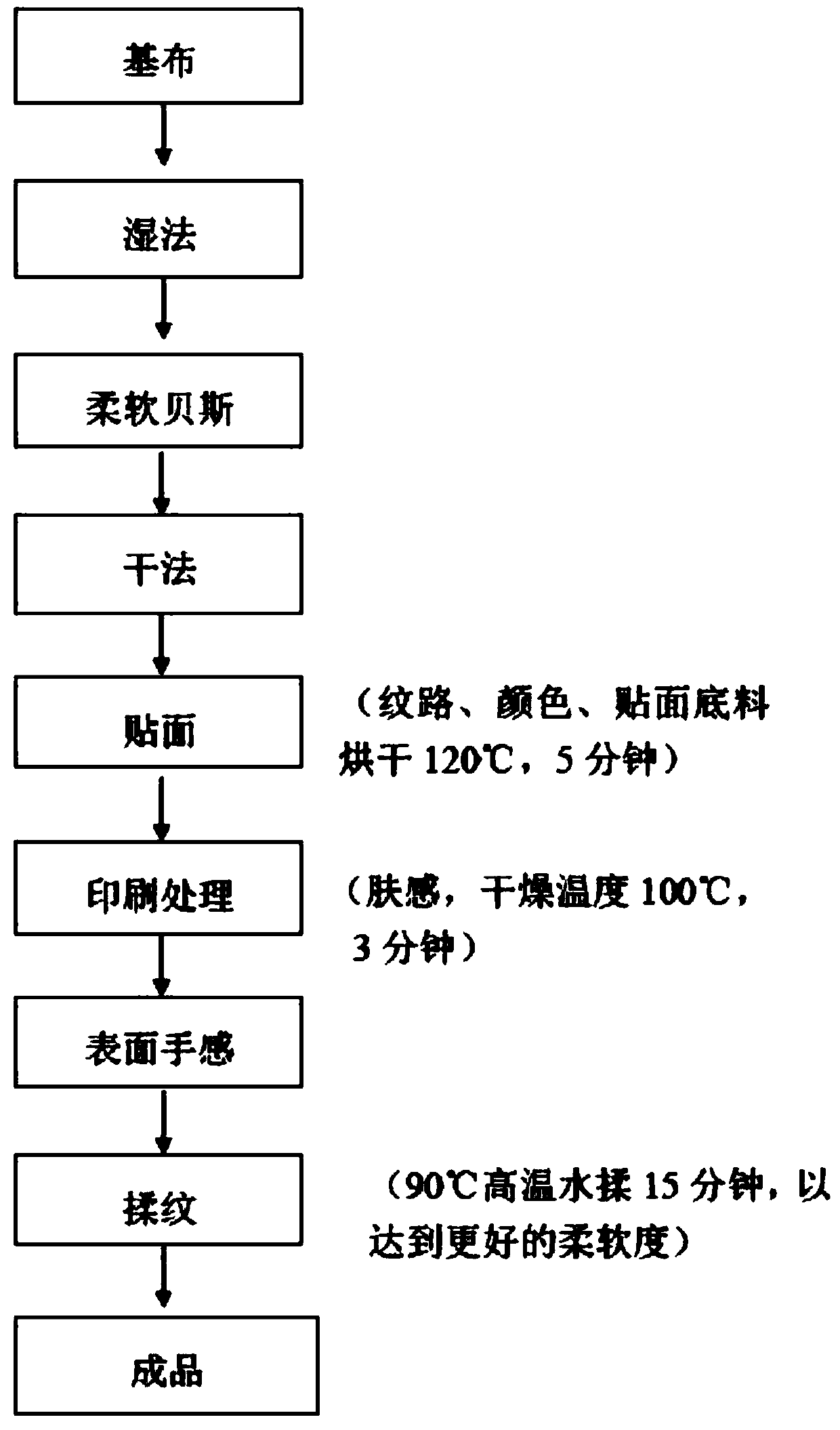

[0022] refer to figure 1 , the preparation method of the environment-friendly protein earphone leather provided by the invention comprises the following steps:

[0023] 1) According to the wet formula designed according to the purpose of the prefabricated protein earphone leather, 100-150 parts by weight of DMF, 5-20 parts by weight of imported wood powder, 4- 8 parts by weight of wet-process resin DS-11, 0.1-1 parts by weight of wet-process resin DS-7, 0.1-0.5 parts by weight of water repellent GY-330, appropriate amount of color paste, after stirring evenly, the viscosity is 1300±20CPS . Scrape on the microfiber elastic cloth, the thickness of the coating is set, washed, and dried to obtain a super soft bass, and the thickness of the coating is controlled to be 1.6mm containing the cloth.

[0024] 2) Add 50-100 parts by weight of DMF and 10-30 parts by weight of ethyl acetate to 50-200 parts by weight of HX-8028 resin, add some required toner, stir evenly, and apply it on ...

Embodiment 1

[0031] 1) According to the wet method formula designed according to the purpose of the prefabricated protein earphone leather, add 100 parts by weight of DMF, 5 parts by weight of imported wood powder, and 4 parts by weight of wet method resin DS into 50 parts by weight of HX-8028 resin -11, 0.1 parts by weight of wet process resin DS-7, 0.5 parts by weight of water repellent GY-330, 2 parts by weight of black 560S color paste, after stirring evenly, the viscosity is 1300±20CPS. Scratched on the microfiber elastic cloth, the thickness of the coating is solidified, washed, and dried to obtain a super soft white bass. Coating thickness is controlled to contain cloth 1.6mm.

[0032] 2) In 50 parts by weight of HX-8028 resin, add 50 parts by weight of DMF, 10 parts by weight of ethyl acetate, add 5 parts by weight of 8609A black powder, stir evenly, apply it on the release paper, after 100 Dry at -120°C to prepare the surface layer, and the thickness of the coating is controlled ...

Embodiment 2

[0037] 1) According to the wet method formula designed according to the purpose of the prefabricated protein earphone leather, add 150 parts by weight of DMF, 20 parts by weight of imported wood powder, and 8 parts by weight of wet method resin DS to 200 parts by weight of HX-8028 resin -11. 1 part by weight of wet-process resin DS-7, 0.5 parts by weight of water repellent GY-330, and 3 parts by weight of black 560s color paste. After stirring evenly, the viscosity is 1300±20CPS. Scratched on the microfiber elastic cloth, the thickness of the coating is solidified, washed, and dried to obtain a super soft white bass. Coating thickness is controlled to contain cloth 1.6mm.

[0038] 2) In 200 parts by weight of HX-8028 resin, add 100 parts by weight of DMF, 30 parts by weight of ethyl acetate, and 7 parts by weight of 8609A black powder. Dry at 100-120°C to obtain a surface layer. Coating thickness is controlled at 0.15mm.

[0039] 3) Apply and scrape the adhesive layer on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com