Leakage-resisting square tunnel for prestressed concrete flexible sockets

A technology of concrete and socket sockets, which is applied in the installation of waterway systems, sewer pipe systems, and ground cables, etc., can solve the problems of accidents, inspections, and high construction costs, so that it is not easy to be squeezed and deformed by the soil, and it is not easy to Easy to crack and sink, the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to clearly illustrate the technical features of the solution, the present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

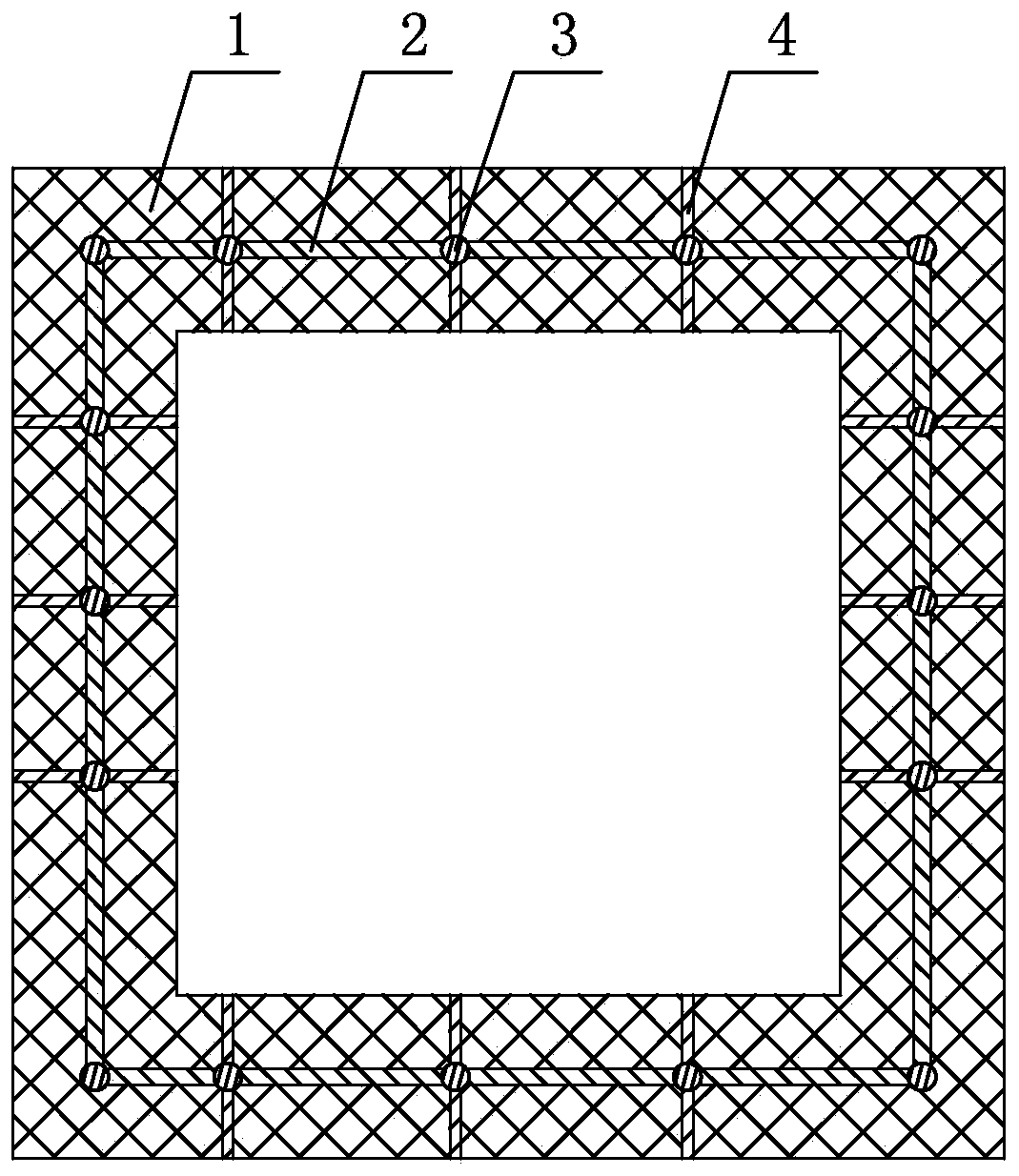

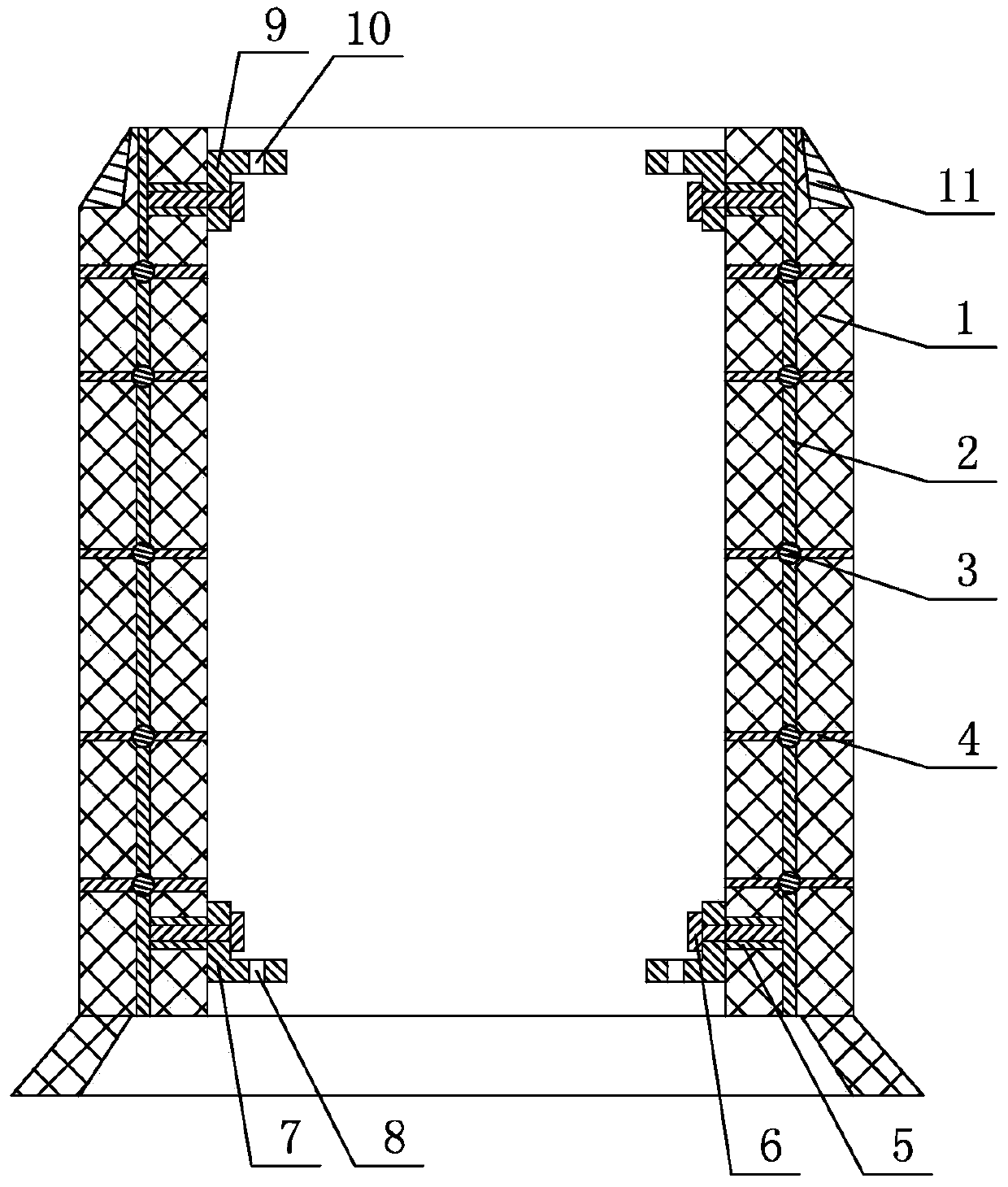

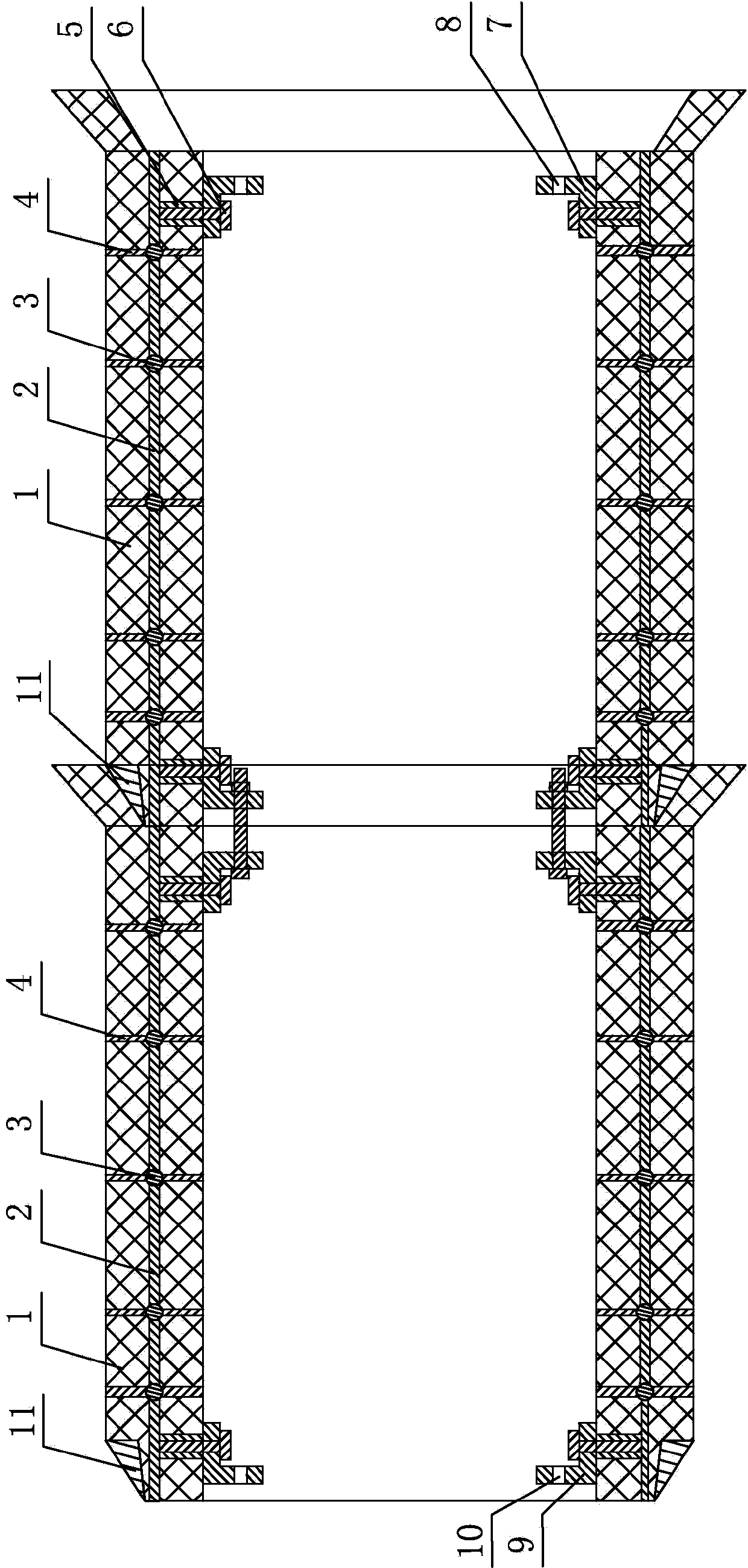

[0013] like Figure 1-3 As shown, an anti-seepage square culvert with a prestressed concrete flexible socket and socket includes a square concrete body 1, and a square wire mesh 2 is arranged inside the square concrete body 1 along the length direction of the square concrete body 1. A number of prestressed steel bars 3 are welded on the steel wire mesh 2 at uniform intervals along the length direction of the square steel mesh 2, and a number of steel bars 4 whose lengths are consistent with the thickness of the square concrete body are evenly spaced on the square steel mesh 2. One end of the square concrete body 1 is provided with a conical socket, and the other end is provided with a socket. On the inner wall of the conical socket and the socket, a number of oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com