Glazed hollow bead polymer mortar and polyurethane composited external thermal insulation system

A composite polyurethane and external wall insulation technology, which is applied in thermal insulation, climate change adaptation, building components, etc., can solve problems such as cracking and leakage of thermal insulation system, unfavorable building energy-saving work, complex construction technology, etc., and achieve good overall formability, The structure is simple and reasonable, and the effect of spraying construction is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

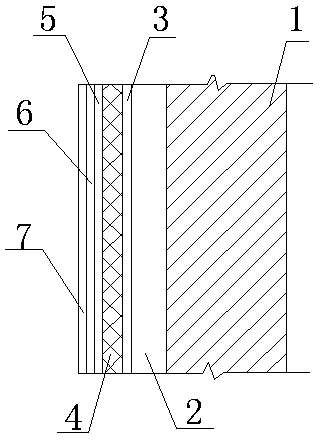

[0016] like figure 1 A vitrified microbead polymer mortar composite polyurethane external wall external thermal insulation system shown, including a base wall 1, and a rigid polyurethane foam 2 glued to one side of the base wall 1; one side of the rigid polyurethane foam 2 An interface mortar 3 is attached; one side of the interface mortar 3 is attached with a vitrified bead thermal insulation mortar 4; one side of the vitrified bead thermal insulation mortar 4 is attached with an anti-crack mortar 5; A flexible water-resistant putty 6 is attached to one side; a coating finish layer 7 is attached to one side of the flexible water-resistant putty 6 .

[0017] Among them, the rigid foam polyurethane 2 is prepared by polyurethane white material and black material in a weight ratio of 1:1; the interface mortar 3 is made of medium-fine sand and cement in a weight ratio of 1:3; the vitrified The microbead thermal insulation mortar 4 is prepared by vitrified microspheres with a wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com