Ceiling structure with arc and manufacturing and mounting method thereof

A technology for a ceiling structure and an installation method, which is applied to building structures, building components, buildings, etc., can solve the problems of low production efficiency, increased overall cost of ceilings, and cumbersome installation, and achieves small occupied space and low overall cost. Easy to transport and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

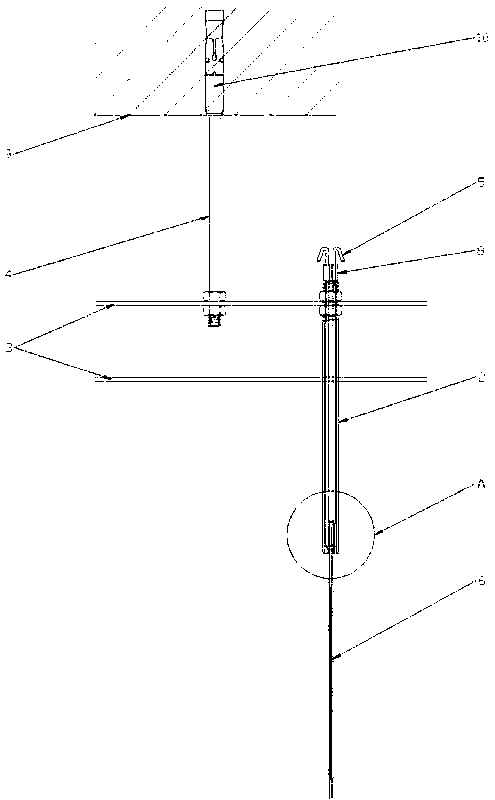

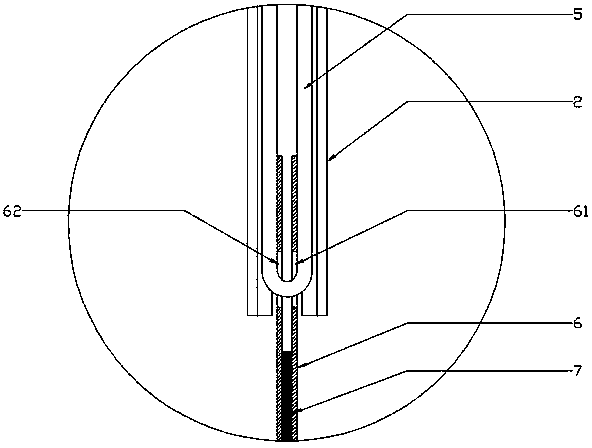

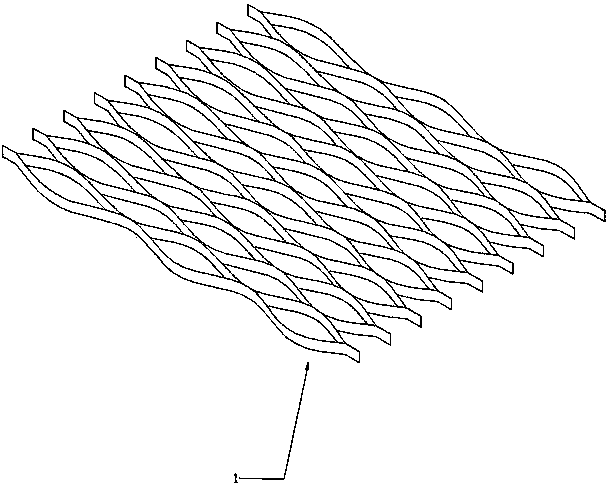

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes a curved ceiling unit 1, a support rod 2, a keel 3, and a suspender 4. The curved ceiling unit 1 is formed by combining several single-piece perforated plates 6 with a wavy side length section. As a result, the specific number of the single punching plate 6 is determined according to the actual ceiling size. In the curved ceiling unit 1, the single punching plates 6 are arranged in such a way that the arc surfaces are tangent to the arc surfaces, and the arc surfaces between the single punch plates 6 are tangent to each other. The connecting agent layer 7 is adhered to each other, and the lower end of the rod body of the support rod 2 is radially provided with a groove matching the single-piece punching plate 6. The width of the groove is three millimeters, and the single-piece punching plate The arc surface between 6 is disposed in the groove tangent to the arc surface, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com