A one-input multi-output coaxial planetary gear gearbox and aerator gearbox

A planetary gear and output shaft technology, applied in the field of gearboxes, can solve the problems of unstable operation of aerators, troublesome installation in space, and non-concentric transmission parts, and achieve the effect of compact and reasonable internal structure, compact structure and large torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

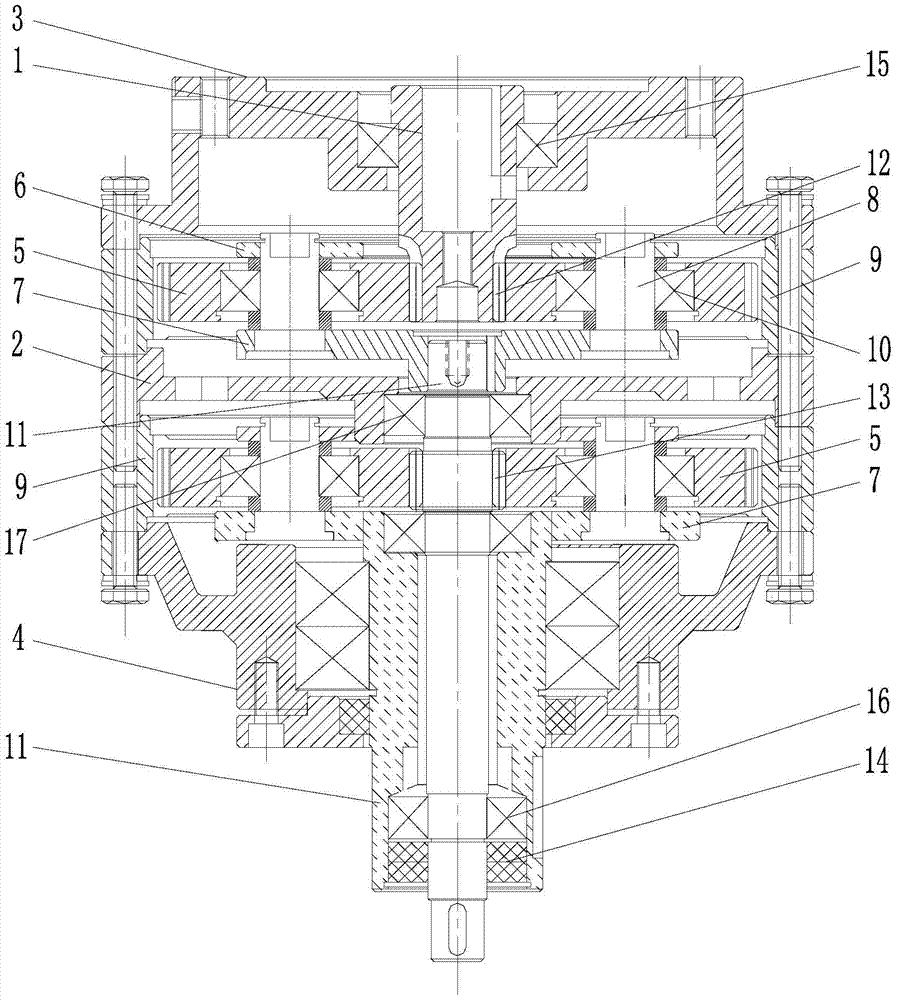

[0030] A coaxial planetary gear transmission with one input and multiple outputs, comprising an input shaft 1, a limit frame 2, an upper end cover 3, a lower end cover 4, and at least two coaxially arranged planetary gear mechanisms;

[0031] The planetary gear mechanism includes a planetary gear 5, a planetary gear connecting flange 6, a planet carrier 7, a planetary shaft 8, an inner ring gear 9, a second bearing 10, a limit frame bearing 17 and an output shaft 11, and the planetary gear connecting flange 6 and The planet carrier 7 is arranged on both sides of the planetary gear 5 and connected by the planetary shaft 8. There are three planetary gears 5, and the three planetary gears 5 are arranged in the inner ring gear 9 in the shape of "pin". The planetary gear 5 and the inner ring gear 9, the output shaft 11 is connected to the planet carrier 7, and the planet shaft 8 is connected to the planet gear 5 through the second bearing 10.

[0032] The input shaft 1 has a first ...

Embodiment 2

[0040] This embodiment is a coaxial planetary gear transmission with one input and two outputs, specifically as follows: a coaxial planetary gear transmission with one input and two outputs, including an input shaft and two coaxial planetary gear mechanisms;

[0041] The planetary gear mechanism includes a planetary gear, a planetary gear connecting flange, a planetary carrier, a planetary shaft, an inner ring gear and an output shaft. The planetary gear connecting flange and the planetary carrier are arranged on both sides of the planetary gear and connected through the planetary shaft. The inner ring gear is meshed, and the output shaft is connected with the planet carrier;

[0042] The input shaft has a first transmission tooth mated with the planetary gear of the first-stage planetary gear mechanism on the power input side;

[0043] The output shaft of the first-stage planetary gear mechanism has a second transmission tooth that is mated with the planetary gear of the seco...

Embodiment 3

[0046]A coaxial planetary gear aerator gearbox with one input and two outputs, the aerator gearbox is the gearbox described in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com