Channel type two-viewing-angle X-ray liquid substance safety check system

A safety inspection and X-ray technology, applied in the field of X-ray digital imaging safety inspection, can solve the problems of not being able to cope with the reverse operation of the conveyor belt of the dual-view device, and cannot limit the usability of the dual-view device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

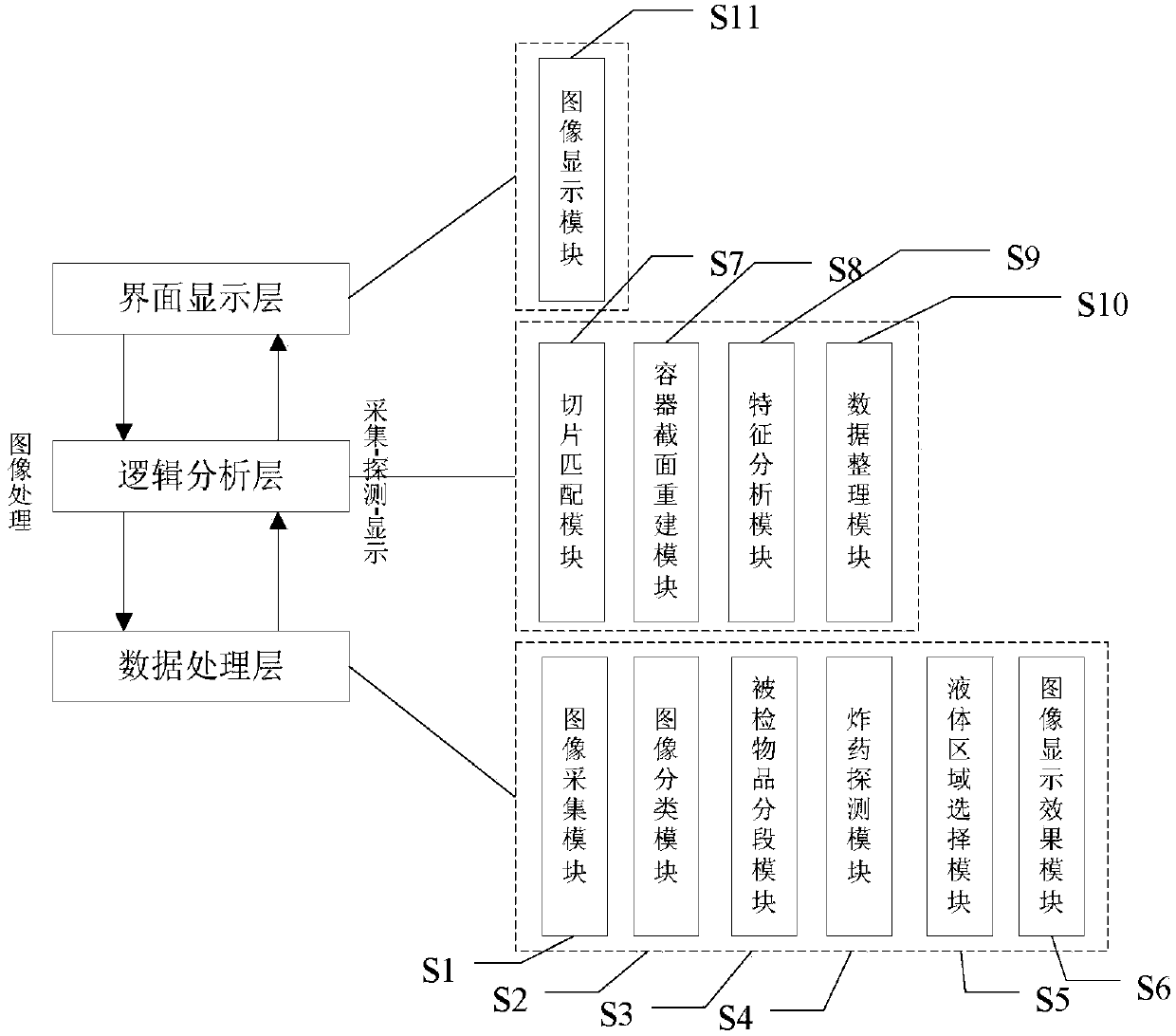

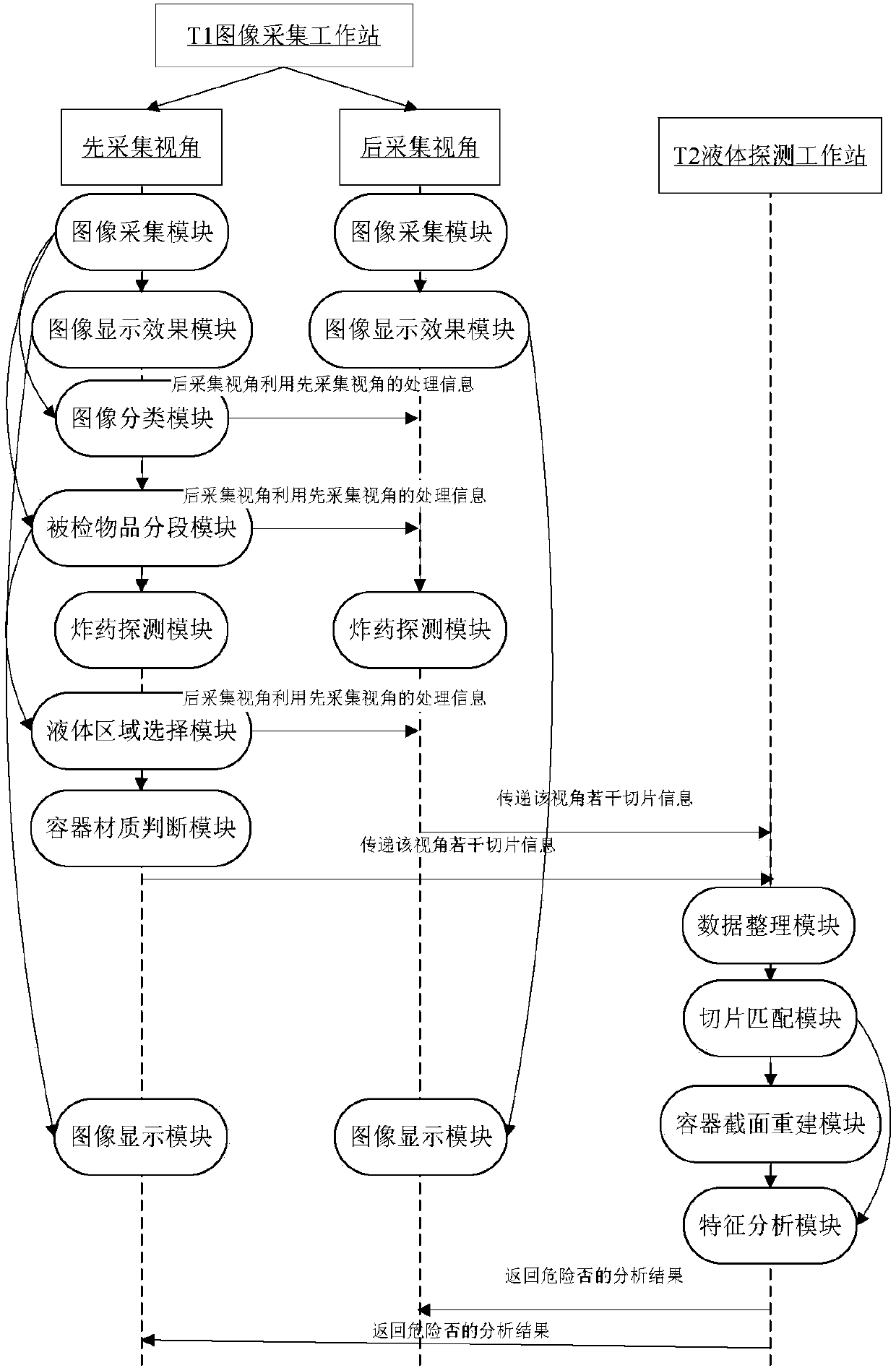

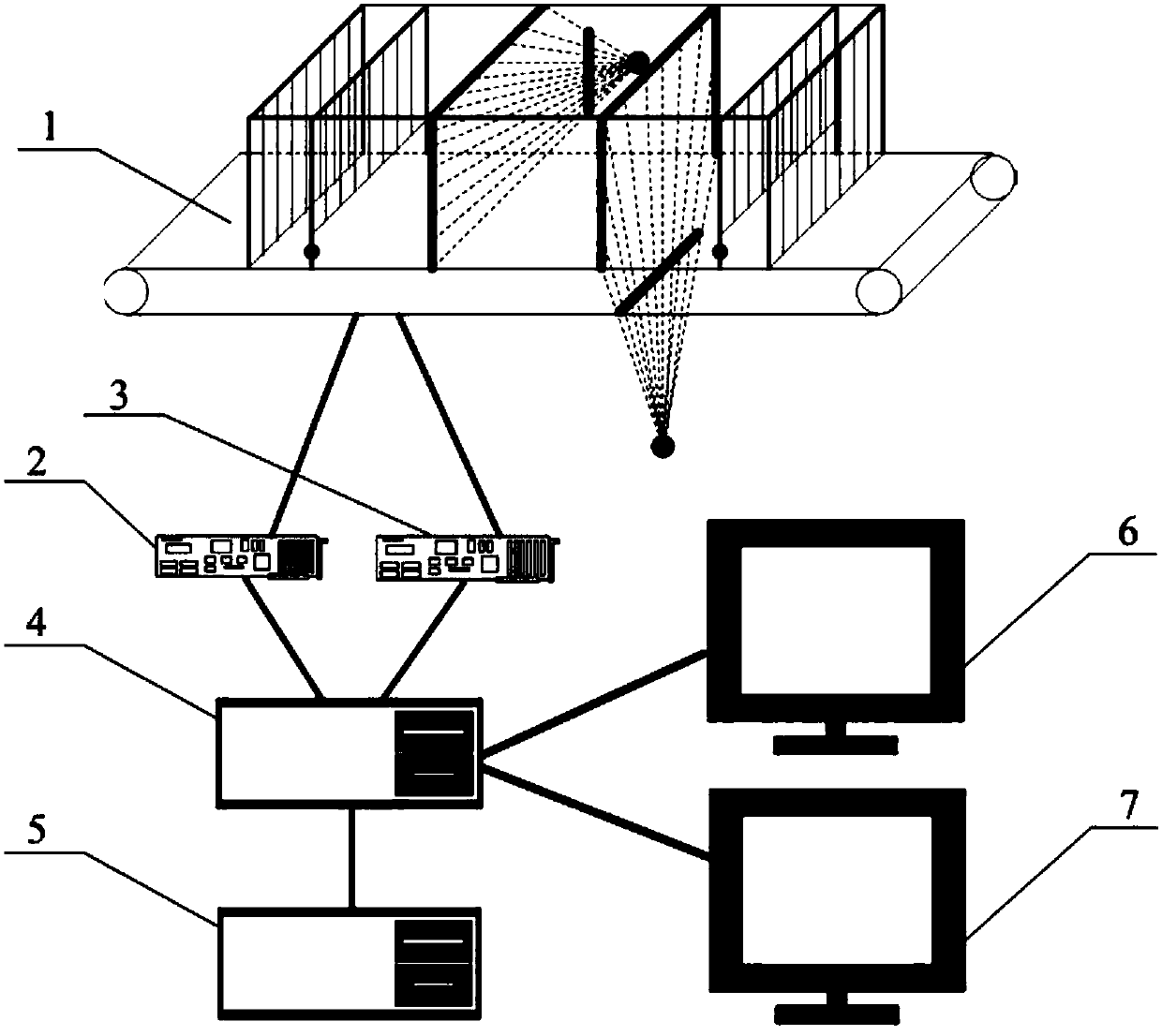

[0034] figure 1 It is a three-layer organization chart of the software system architecture of the channel-type dual-view X-ray liquid article safety inspection system of the present invention. As mentioned above, there are a total of 12 modules, which are distributed in the data processing layer, logical analysis layer, and interface display layer in terms of organizational hierarchy. When in the collection-detection-display working mode, the present invention triggers the data processing layer to work from the bottom layer, transmits the result to the logic analysis layer, and then transmits the analysis result to the interface display layer for display; when in the image processing working mode, the present invention The work is triggered by the upper layer, the button of the interface display layer is triggered, and the command is passed to the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com