Similar blue cheese and preparation method thereof

A kind of blue cheese, a kind of technology, applied in the field of food processing, can solve the problems such as lack, and achieve the effect of short ripening cycle, simple and easy preparation method, and soft flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

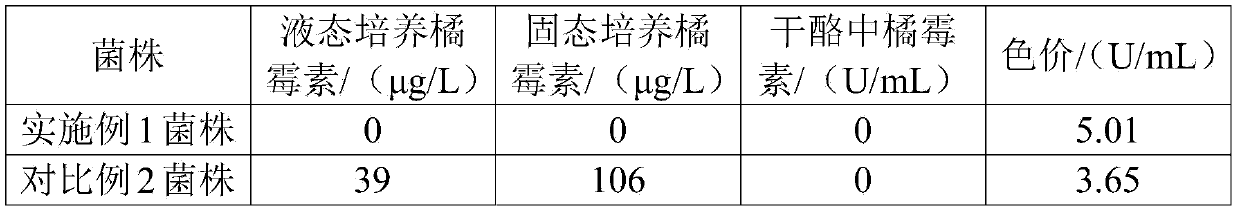

Examples

Embodiment 1

[0041] (1) Sterilize 100L of fresh milk at 72°C for 15 seconds, then cool to 30°C, add acetic acid to make the pH of the raw milk 6.5, add 1.2g of rennet, and curd the milk for 50 minutes to obtain curd.

[0042] (2) Cut the curd described in step (1) into lumps with a steel wire knife with a distance between blades of 10 mm, stir for 30 minutes and drain the whey, add 2% salt, add 0.5% Monascus culture solution, and stir evenly After the mold is molded at 18°C; no pressing is performed during molding, and flipping is performed (the curd is turned over for the first time after 15 minutes into the mold, turned over for the second time 30 minutes after the first turning, and then turned over for the third time at an interval of 1 hour, and then turned over again at an interval of 1 hour. Turn over for the fourth time in 1.5 hours, then turn over for the fifth time at an interval of 2 hours, turn over for the sixth time at an interval of 5 hours, and finally turn over for the seve...

Embodiment 2

[0047] (1) Sterilize 100L of fresh milk at 70°C for 60s, then cool to 33°C, add citric acid to make the pH of the raw milk 6.4, add 1.8g of rennet for 30min to obtain curd.

[0048] (2) Cut the curd described in step (1) into lumps with a steel wire knife with a blade spacing of 30 mm, stir for 30 minutes and drain the whey, add 3% salt, add 5% Monascus nutrient solution, and stir evenly Back-entry mold is formed at 15 ℃; During forming, do not carry out pressing, turn over on time (same as embodiment 1), to promote the further discharge of whey.

[0049] (3) The curd is matured after taking it out. The ripening process is to puncture after demoulding, then mature at a temperature of 20°C for 10 days, continue to mature at a temperature of 15°C for 10 days, and finally continue to mature at a temperature of 8°C for 15 days; During this period, the relative humidity of the environment where the cheese was placed was 95%.

[0050] Wherein, the Monascus culture solution is prepa...

Embodiment 3

[0053] (1) Sterilize 100L of fresh milk at 71°C for 36s, then cool to 32°C, add lactic acid to make the pH of the raw milk 6.3, add 1.6g of rennet for 60min to obtain curd.

[0054] (2) Cut the curd described in step (1) into lumps with a steel wire knife with a blade spacing of 15 mm, stir for 30 minutes and drain the whey, add 2.5% salt, add 2.5% Monascus culture solution, and stir evenly Back-entry mold is formed at 25 ℃; During forming, do not press, turn over on time (same as embodiment 1), to promote the further discharge of whey.

[0055] (3) Ripe the curd after taking it out. The ripening process is to puncture for the first time after demoulding, then ripen at 22°C for 7 days, continue to ripen at 17°C for 7 days, and finally continue to ripen at 6°C for 25 days ; The relative humidity of the environment where the cheese is placed during the entire ripening period is 85%.

[0056] Wherein, the Monascus culture solution is prepared by the following method: the Monascu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com