Mellow and aromatic lard and making method thereof

A lard, mellow technology, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of unfavorable production of general enterprises, light color of products, high equipment requirements, and achieve good antioxidant capacity, soft flavor and high removal rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

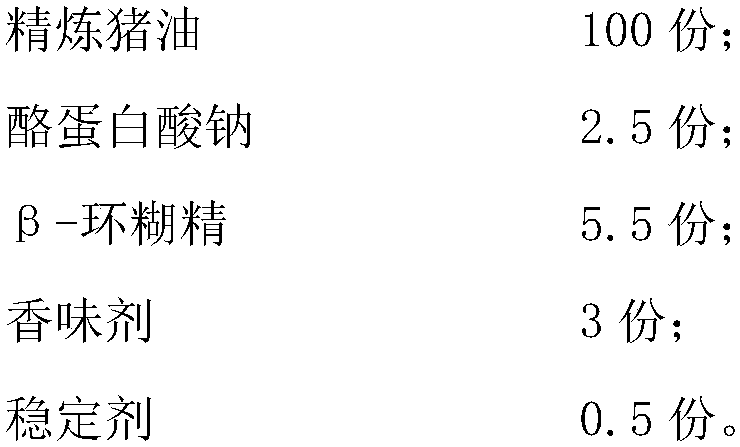

Embodiment 1

[0027] A preparation method of mellow lard, the specific steps are as follows:

[0028] 1) Pretreatment: Remove the fresh pork fat from muscle, broken bones, lymph, blood and other non-fat tissues, clean it, and after passing the inspection, twist the fat into a minced dough and store it in a freezer at -10℃ 4h to the fat mince all frozen solid;

[0029] 2) Ultrasonic-steaming extraction: The frozen fat mince is ultrasonically treated at a power of 400w and a frequency of 30Hz for 45min. Due to the ultrasonic heating, there is no need to reheat it at this time. Then use 130℃ steam for constant temperature heating and extraction, every 5min Measure the extract until the amount of the extract does not change, contact the steam to heat the extraction, and then use deionized water to wash the extract 3 times to remove impurities to obtain crude oil;

[0030] 3) Sediment filtration: The crude oil is allowed to stand for 1-2 days to settle, and the upper layer of oil is removed for inspec...

Embodiment 2

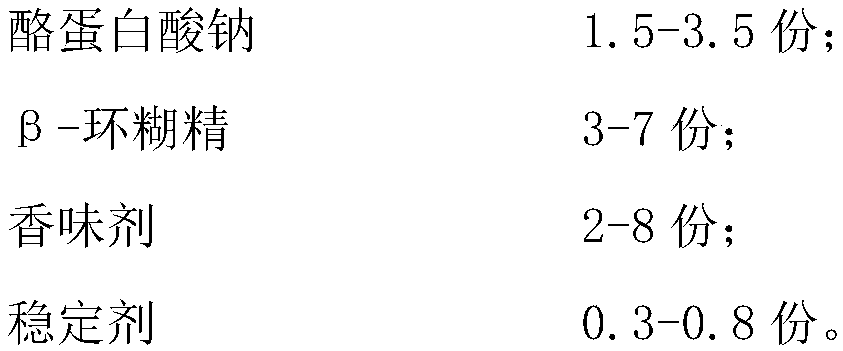

[0035] This example is the same as Example 1, except that the mellow lard contains the following ingredients: 100 parts refined lard; 1.5 parts sodium caseinate; 3 parts β-cyclodextrin; 2 parts fragrance; 0.3 parts stabilizer.

Embodiment 3

[0037] This example is the same as Example 1, except that the mellow lard contains the following ingredients: 100 parts of refined lard; 3.5 parts of sodium caseinate; 7 parts of β-cyclodextrin; 8 parts of flavoring agent; 0.8 parts of stabilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com