Automatic discharging device of rolling machine

An automatic discharge device and kneading machine technology, which is applied in the field of matching with traditional kneading machines, can solve problems affecting kneading operations and pollution, and achieve the effects of simple structure, simple installation and maintenance, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

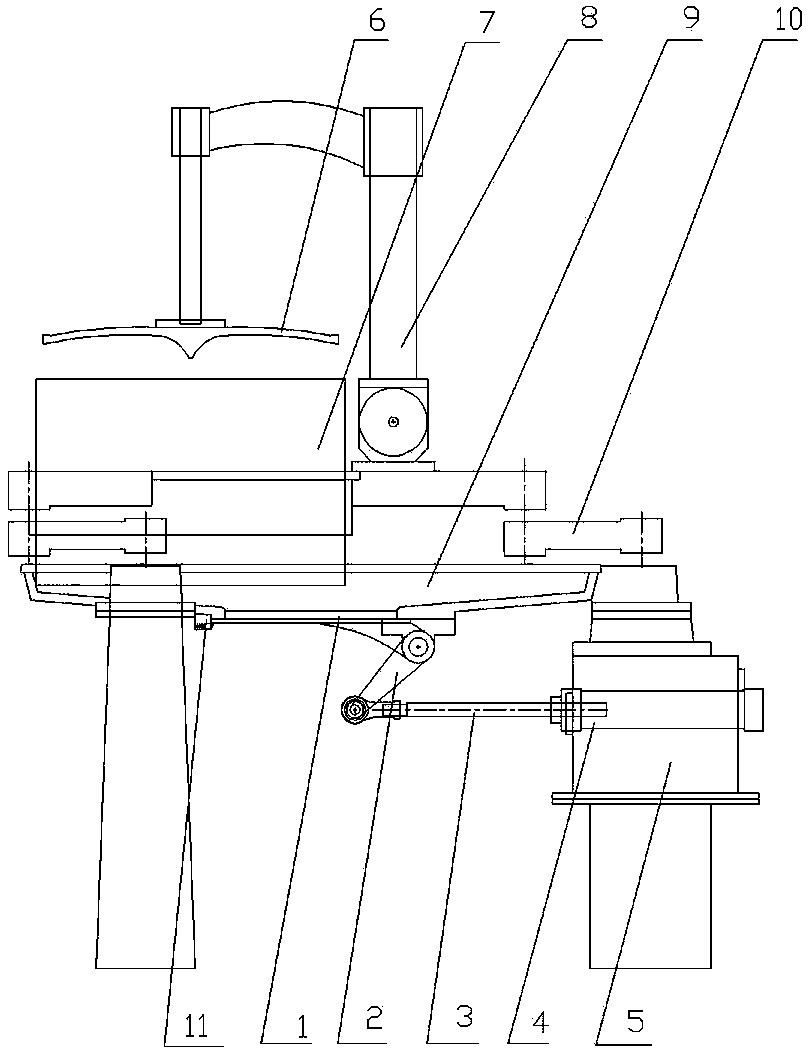

[0011] The tea kneading machine is composed of rocker arm 10, kneading disc 9, pressurized screw rod 8, kneading barrel 7, pressurized cover 6, kneading machine kneading disc base 5, discharge door lock 11, discharge door 1, etc. The automatic discharge device of the kneading machine is composed of a discharge door 1, a discharge door lifting connecting rod 2, a pneumatic element telescopic rod 3, and a pneumatic element 4. Among them: the discharge door lifting connecting rod 2 is installed on the discharge door 1, the pneumatic element telescopic rod 3 is connected with the pneumatic element 4 and the discharging door lifting connecting rod 2, the pneumatic element 3 is installed on the kneading machine kneading plate base 5, the The automatic discharge device of the kneading machine has the characteristics of reasonable structure, simple and portable, easy installation and maintenance, low pressure level, and safe use, which creates conditions for automatic loading and unloa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com