Production method of calamine lotion

A technology of calamine lotion and a production method, which are applied in the directions of pharmaceutical formulations, medical preparations without active ingredients, and medical preparations containing active ingredients, etc., can solve the difficulty of controlling the limit of microorganisms, and the suspension stability of the calamine lotion. problems such as poor performance, to achieve good suspension stability, ensure bacteriostatic effect, and reduce the risk of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

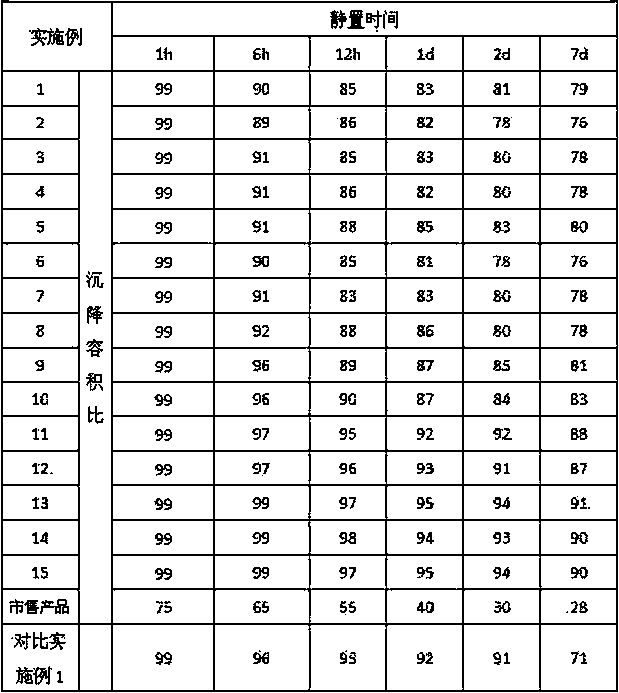

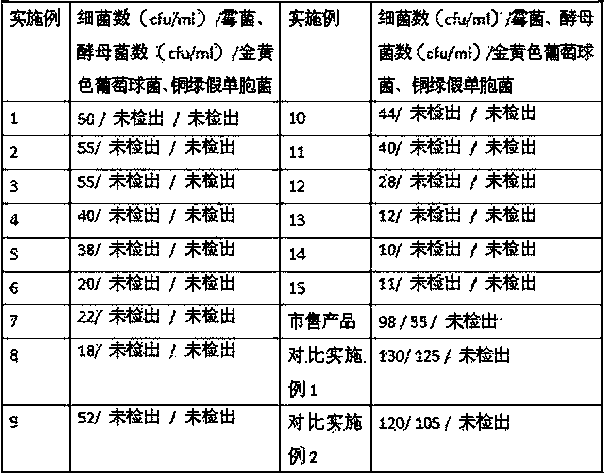

Examples

Embodiment 1

[0030] prescription:

[0031] Calamine very fine powder 50g;

[0032] Zinc oxide ultrafine powder 15g;

[0033] Medicinal glycerin 50g.

[0034] Put 50g of calamine ultra-fine powder and 15g of zinc oxide ultra-fine powder into the mortar, add appropriate amount of sterilized water to moisten, grind, pay attention to replenish water during the process, keep the powder moist, after the grinding becomes viscous, add Rinse with sterile water and filter. Then add 50g of medicinal glycerin, stir and mix to form a viscous shape, add appropriate amount of sterilized water and stir at high speed for 30min to prepare a suspension with a mass concentration of 20%, which is the finished product.

Embodiment 2

[0036] prescription:

[0037] Calamine very fine powder 50g;

[0038] Zinc oxide ultrafine powder 150g;

[0039] Medicinal glycerin 50g.

[0040] Put 50g of calamine ultra-fine powder and 150g of zinc oxide ultra-fine powder into the mortar, add appropriate amount of sterilized water to moisten, and grind. Pay attention to replenish water during the process to keep the powder moist. After the grinding becomes viscous, add Rinse with sterile water and filter. Then add 50g of medicinal glycerin, stir and mix to form a viscous shape, add appropriate amount of sterilized water and stir at high speed for 30 minutes to prepare a suspension with a mass concentration of 25%, which is the finished product.

Embodiment 3

[0042] prescription:

[0043] Calamine very fine powder 50g;

[0044] Zinc oxide ultrafine powder 100g;

[0045] Medicinal glycerin 50g.

[0046] Put 50g of calamine ultra-fine powder and 100g of zinc oxide ultra-fine powder into the mortar, add appropriate amount of sterilized water to moisten, grind, pay attention to replenish water during the process, keep the powder moist, after the grinding becomes viscous, add Rinse with sterile water and filter. Then add 50g of medicinal glycerin, stir and mix to form a viscous shape, add appropriate amount of sterilized water and stir at high speed for 30 minutes to prepare a suspension with a mass concentration of 25%, which is the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com