Low-fluorine environment-friendly type aqueous film-forming foam fire extinguishing agent and preparation method thereof

A foam fire extinguishing agent, an environmentally friendly technology, applied in fire protection equipment and other directions, can solve the problem of less research on the combination of fluorocarbon surfactants and silicon-containing surfactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The raw material composition and preparation method of the present invention can be summarized as follows:

[0018] The raw material composition of the invention includes: fluorocarbon surfactant, hydrocarbon surfactant, silicon-containing surfactant, organic solvent, anti-burning agent, foam stabilizer, preservative and water.

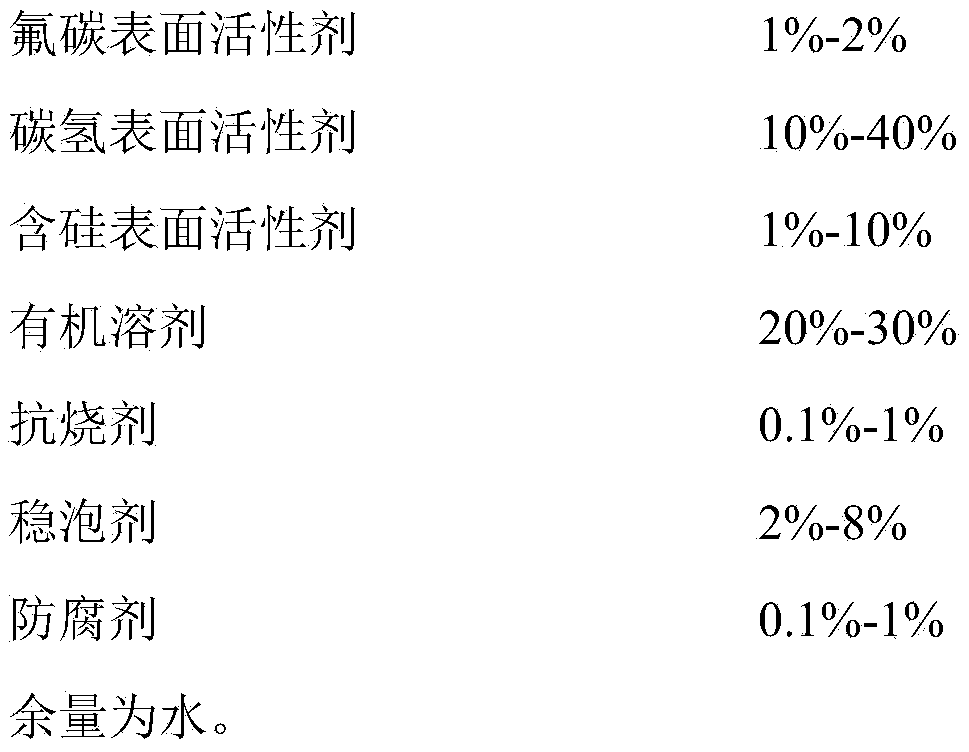

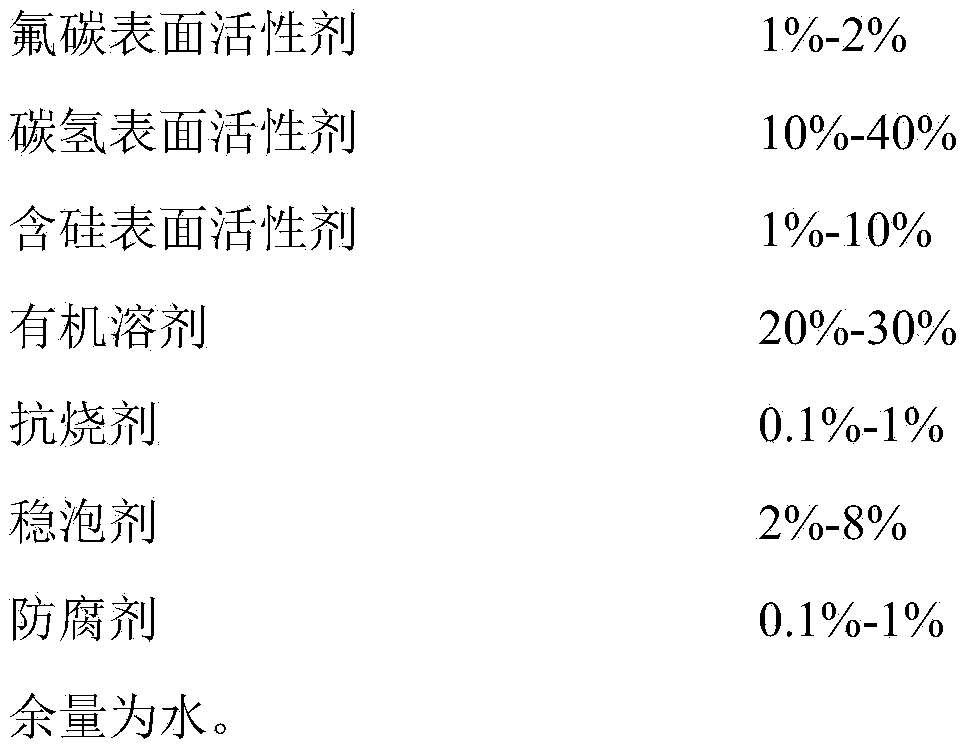

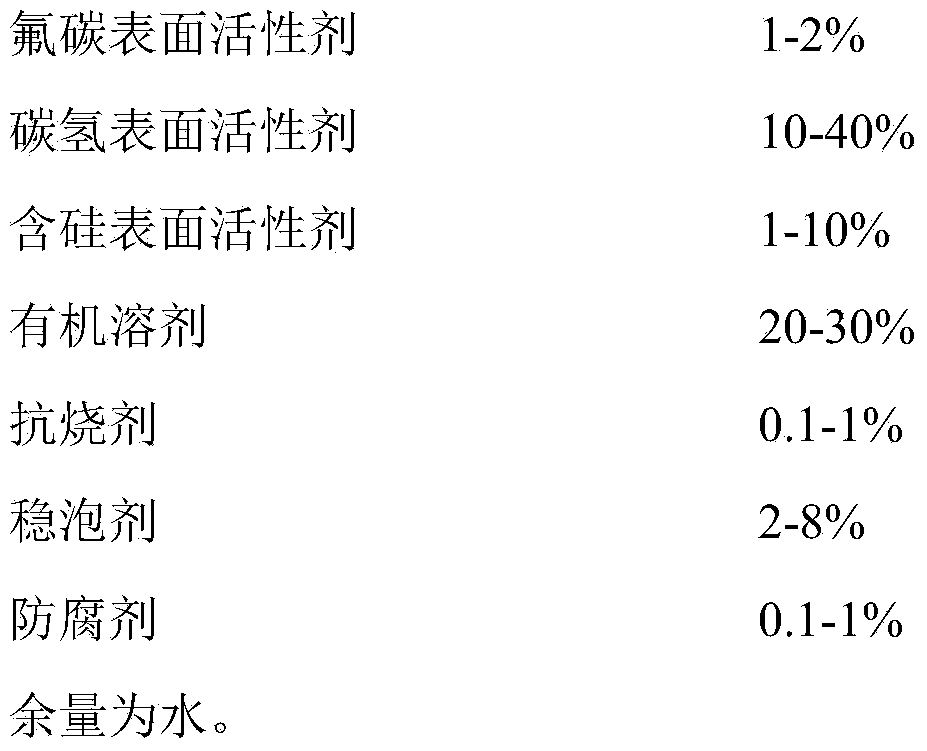

[0019] The combined formula of the present invention is calculated by weight percentage:

[0020]

[0021] The fluorocarbon surfactant used in the present invention is cationic perfluoroalkyl quaternary ammonium iodide FC-911 or non-ionic perfluoroalkylene oxide surfactant FC-001 or zwitterionic fluorocarbon surfactant Ee607 The function is to reduce the surface tension of the water, so that the foam solution can form a water film on the oil surface and spread quickly, sealing the oil surface, so as to achieve rapid fire extinguishing.

[0022] The hydrocarbon surfactant used in the present invention is an amphoteric imidazoline or betaine with 12-18 c...

Embodiment 2

[0031] Weigh FC-911 1kg, Ee607 1kg, ethylene glycol 20kg, diethylene glycol monobutyl ether 5kg, and mix well to form Mixture A; weigh 30kg of imidazoline, 3kg of water-soluble silicone oil, and 30kg of water and mix well to form Mixture B ; Add B to A and stir; Weigh 3kg of urea, 0.3kg of xanthan gum and dry mix evenly, slowly add to A, add 0.5kg of sodium benzoate, and finally add water to 100kg, and mix well.

Embodiment 3

[0033] Weigh 2kg of FC-911, 20kg of ethylene glycol, and 5kg of diethylene glycol monobutyl ether, and mix them to form mixture A; weigh 30kg of betaine BS-12, 2kg of water-soluble silicone oil, and 30kg of water to form mixture B; Add to A and stir; weigh 5 kg of urea, 0.2 kg of xanthan gum and dry mix evenly, slowly add to A, add 0.3 kg of potassium sorbate, and finally add water to 100 kg, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com